Valve with Best Price from 50year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

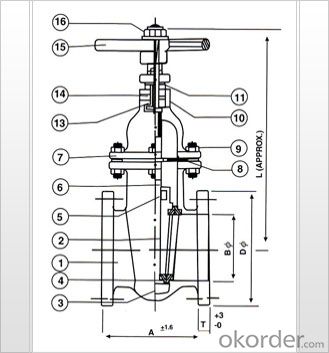

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.

- Q: Measure the temperature with a thermocouple, and then how to make the valve open when the temperature reaches a certain value. When the temperature is lowered, will the valve be closed?Or tell my brother what is the knowledge, I can see it myself. Good. How much extra?!

- Switching type (one on and off)Block digital display with the upper and lower limit control valve opening and closing is goodProbably more than 100Regulating type (to keep temperature at a constant value)With PID valve position regulator can be very good controlAbout 300 more

- Q: Pump, valve, these belong to the material?

- Pumps, valves are electromechanical equipment, belonging to a class of hardware fittings, but not material!

- Q: What does the whole copper valve mean?

- Except the handwheel, all the material of the valve body is copper

- Q: What kind of valve is it? How do you see the status of the switch?

- This is a ball valve, that is, usually said cut-off valve, to determine the switch state is carefully look at, there is a switch on the status of the arrow, you will understand.

- Q: Who knows which kind of water valve is good?

- Classification of domestic valves:pipeline valveBathroom valves, kitchen valves, etc faucetsPipeline valve is generally sealed with rubber valve is better, rubber sealed valve sealing performance is very good and durable;Bathroom valves, kitchen valves and other faucets will use copper into the Dian valve, copper valve is not rusty, durable. ,Hope to help you.

- Q: What is the valve before and after the pump?

- Pump in front of the gate valve + one-way valve, after the pump connected valve, so that in the regulation can be clearly aware of the actual pump lift is large, without the impact of system pressure.Valve is the general name of pumps and valves.A valve that is not used in a pump or with a pump.Pump and valve are often associated with the use of the occasion. In other words, where there is a pump, there is usually a valve, where a valve is often required. They are all used for liquid delivery.

- Q: How to check if the gas valve is open?

- The gas valve has a handle, and the handle is parallel to the pipe and is opened, and the vertical is closed. If there is no handle, there is a rectangular main handle on the valve, the principle is the same as above.

- Q: What are the technical requirements of valves, such as "Z15W-25T"?

- Threaded copper gate valve. Z15W-25T is a valve type, wherein each byte has a specific meaning, see detailed People's Republic of China machinery industry standard JB/T 308 "valve model establishment method", "JB/T" model establishment of power station valveValve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Model refers to the product performance, specifications, sizes, materials and other indicators of the set of code.

- Q: What is the BV valve?

- It should be the meaning of BREATH VALVE, breather valve

Send your message to us

Valve with Best Price from 50year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords