UV Resistance WPC Decking Outdoor Most Popular Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

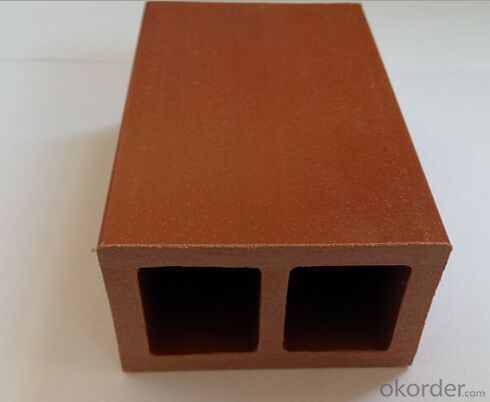

Introduction of UV Resistance WPC Decking Outdoor:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of UV Resistance WPC Decking Outdoor:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of UV Resistance WPC Decking Outdoor:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of UV Resistance WPC Decking Outdoor:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of UV Resistance WPC Decking Outdoor:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: How about the plastic floor?

- Exactly the PVC floor. Not everyone understands the normal plastic. Many advantages. At present, foreign market point eighty percent. Domestic began. Many people don't know yet. Many advantages:

- Q: Now decorated with qVC plastic floor can do

- Can be used, PVC plastic floor is widely used such as

- Q: Wood floors and wood floors in the outdoor anticorrosion materials?

- Wood floor is a new type of environment-friendly wood plastic composite products, in the production process of medium and high density fiberboard in guaiacol, recycled plastic granulator made by adding wood plastic composites, then the extrusion group made of wood.

- Q: PVC plastic floor defects

- Homogeneous PVC floor1, poor resistance to pollution, regular waxing maintenance2, containing a certain amount of stone powder, the surface without PVC wear-resistant layer3, afraid of cigarette burns4, hard texture, soft feel than PVC composite floor5, compared to the composite PVC floor multicolor printing layer, the color is more single, not diversity6, the fire resistance of composite PVC floor

- Q: How many yuan per square meter of plastic floor

- Customer: why is your price so cheap? Shanghai and the United States to answer: factory direct sales! 3, the customer asked: your home a few years ago? Shanghai, Shanghai and the United States replied: plastic floor 50 yuan per square shelf life of 6 years, the price of $180 per square shelf for 15 years! Please understand Shanghai Hu Mei plastic floor for the sports ground facilities, good floor to prevent injuries, foot comfort

- Q: The floor of the wooden floor is a good line of plastic or wood

- Plastic bar, wood is worried that the water will become black and ugly

- Q: Plastic film on the floor for a long time with what method is easier to remove

- No matter what the film is on the ceramic tile and it is not the same material. I would like to use the principle of thermal expansion and contraction of the porcelain and film separation.

- Q: How much is a plastic floor in a ping pong court?

- Table Tennis plastic floor brand domestic price per square meter from dozens of dollars to more than and 100 within this range, foreign imports are more than and 100 to two hundred or three hundred

- Q: What is the plastic floor?

- 3.0mm (mm), the scope of application: family room, hotels, restaurants, airports, schools, hospitals, clinics, light industrial factories, offices, offices, laboratories, shopping malls, entertainment, etc. all kinds of cylindrical wall and ground of indoor space, grade quality, special purpose: wear pattern: wood material.: PVC. Product features: vidon material compared with traditional materials, stone plastic floor model as an alternative to products from the function and purpose has its irreplaceable advantages: A, rich colors, easy splicing,.... Manufacturer of plastic floor is Suzhou Zhaoshun Trade Co. Ltd., plastic floor brand: vidon, specifications: place of origin: Taiwan, wandon, specifications: 178mm brand:

- Q: Home decoration, floor requirements should be very flat

- Winter PVC plastic floor construction must have the conditions:(1) the ground is wet and dry;(2) the ground temperature is low, it is difficult to fully adhere to the ground decoration materials and the ground;

Send your message to us

UV Resistance WPC Decking Outdoor Most Popular Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords