Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

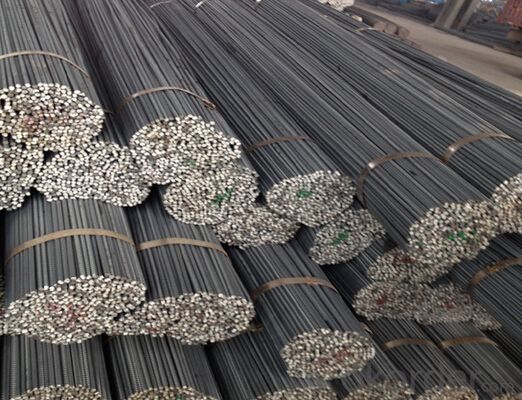

Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

Details of the Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: Can steel rebars be used in seismic-resistant construction?

- Yes, steel rebars can be used in seismic-resistant construction. Steel rebars are commonly used in reinforced concrete structures to enhance their strength and durability, making them suitable for withstanding seismic forces. By reinforcing the concrete with steel rebars, the structure becomes more resistant to the lateral and vertical movements caused by earthquakes, thereby improving the building's seismic performance.

- Q: How are steel rebars marked for identification on construction sites?

- Steel rebars are typically marked for identification on construction sites using a variety of methods. The most common method is through the use of tags or labels that are attached to the rebars. These tags often contain important information such as the diameter, grade, and length of the rebar, as well as any additional specifications or codes that may be required. In addition to tags, rebars may also be marked using paint or ink. This can be done by either spraying or stenciling the required information directly onto the surface of the rebar. Paint or ink markings are often used for temporary identification purposes or when tags are not feasible. Another method of marking rebars is through the use of colored plastic or vinyl caps. These caps are placed on the ends of the rebars and are typically color-coded to indicate various characteristics such as the size or type of rebar. This method allows for quick and easy visual identification on the construction site. It is important to note that the specific method of marking rebars may vary depending on local regulations, project requirements, or the preferences of the construction company or engineer. The goal of these markings is to ensure that rebars can be easily identified and sorted during construction, helping to ensure proper installation and adherence to design specifications.

- Q: What is the minimum cover required for steel rebars in concrete structures?

- The minimum cover required for steel rebars in concrete structures typically depends on the specific design requirements and local building codes. However, a commonly accepted guideline is to have a minimum cover of at least 1.5 inches (or 40 millimeters) for rebars in reinforced concrete structures. This cover helps protect the steel reinforcement from corrosion, fire, and other potential hazards, ensuring the durability and strength of the concrete structure.

- Q: What are the guidelines for proper placement of steel rebars in concrete structures?

- The proper placement of steel rebars in concrete structures is essential to ensure the structural integrity and durability of the construction. Here are some guidelines to follow for the correct placement of rebars: 1. Design Considerations: The first step is to refer to the structural drawings and specifications provided by the engineer. These documents will outline the required rebar sizes, spacing, and any specific details or arrangements needed for the project. 2. Rebar Size and Spacing: The size and spacing of rebars are determined based on the structural requirements and load-bearing capacity of the concrete structure. The diameter and spacing of the rebars should adhere to the design specifications to provide adequate reinforcement. 3. Concrete Cover: The concrete cover refers to the distance between the outer surface of the rebar and the edge of the concrete. This cover protects the rebars from corrosion and provides fire resistance. It is crucial to maintain the specified concrete cover to ensure the longevity of the rebars. 4. Lap Length: In cases where rebars need to be spliced or joined together, a lap length is specified. The lap length ensures sufficient overlap for the transfer of stress between the rebars and prevents any weak points in the structure. 5. Alignment and Positioning: Rebars should be properly aligned and positioned within the concrete formwork. They should be placed in the center of the concrete section to effectively resist tension and compression forces. The use of spacers or chairs can help maintain the desired rebar position during the pouring and setting of the concrete. 6. Clearances and Edge Distance: Adequate clearances must be maintained between rebars to allow for proper concrete flow during casting. Similarly, minimum edge distances should be maintained to prevent rebar corrosion and ensure proper concrete cover. 7. Tying and Fixing: Rebars should be securely tied and fixed at intersections to prevent displacement during concrete placement. Properly tying the rebars using wire or approved connectors helps maintain their position and ensures the structural integrity of the concrete. 8. Inspection and Quality Control: Regular inspections should be conducted during the concrete pouring process to verify that the rebars are placed correctly and according to the design specifications. Any deviations or discrepancies should be addressed promptly to avoid compromising the structural integrity of the concrete structure. By following these guidelines, construction professionals can ensure the proper placement of steel rebars in concrete structures, resulting in safe and durable constructions that can withstand the design loads and provide long-term structural stability.

- Q: Can steel rebars be used in reinforced masonry?

- Yes, steel rebars can be used in reinforced masonry. Reinforced masonry refers to the use of steel reinforcement within masonry walls, columns, or other structural elements to increase their strength and resistance to various forces. Steel rebars are commonly used as reinforcement in reinforced masonry due to their high tensile strength and ability to withstand bending and stretching forces. The rebars are typically embedded within the masonry units or mortar, creating a composite structure that can resist compressive, tensile, and shear forces more effectively. The use of steel rebars in reinforced masonry enhances the structural integrity, durability, and overall performance of the masonry construction, making it a widely accepted and practiced technique in the industry.

- Q: How do steel rebars affect the maintenance requirements of a structure?

- The maintenance requirements of a structure are significantly influenced by steel rebars, also known as reinforcing bars. These bars, which are constructed from steel, are embedded in concrete to provide strength and durability to the structure. Enhancing the overall structural integrity of a building or infrastructure is one of the primary ways in which steel rebars impact maintenance. The presence of rebars greatly increases the load-bearing capacity of concrete, enabling it to withstand external forces such as wind, earthquakes, and heavy loads. This reinforcement helps to prevent cracks, deformations, and structural failures, ultimately reducing the maintenance needs of a structure. Moreover, steel rebars also contribute to the longevity of a structure. By offering tensile strength to concrete, they shield it from the negative effects of shrinkage and expansion caused by temperature fluctuations. These rebars act as a framework that holds the concrete together, minimizing the risk of cracks and ensuring the structural stability of the building over time. As a result, the maintenance requirements are reduced as the structure remains intact and resilient against environmental factors. Nevertheless, it is important to acknowledge that steel rebars can also impact maintenance requirements in specific situations. If the rebars are not designed, installed, or protected properly, they can be vulnerable to corrosion. Corrosion occurs when moisture and oxygen penetrate the concrete and reach the steel, causing it to rust. Rusting rebars can lead to the expansion of steel, creating internal pressure that can result in cracking and spalling of the concrete. Consequently, regular inspections, maintenance, and protection measures such as epoxy coating or cathodic protection systems are necessary to prevent corrosion and ensure the longevity of the structure. In conclusion, steel rebars have a positive impact on the maintenance requirements of a structure by enhancing its strength, durability, and longevity. They decrease the need for repairs and maintenance caused by structural failures and increase the overall resilience against external forces. However, proper design, installation, and protection of rebars are crucial to avoid corrosion-related issues that could increase maintenance needs.

- Q: How do steel rebars affect the overall workability of concrete?

- Steel rebars can greatly enhance the overall workability of concrete. By reinforcing the concrete, rebars provide structural integrity and strength, allowing for better handling and shaping during construction. Additionally, the presence of rebars helps to prevent cracking and increase the durability of the concrete structure.

- Q: How do steel rebars affect the overall construction cost?

- Steel rebars can significantly impact the overall construction cost. While they add to the initial expenses, their use enhances the structural integrity and durability of the building, resulting in long-term cost savings by reducing maintenance and repair expenses. Additionally, steel rebars provide strength and reinforcement, allowing for the construction of taller and more complex structures, which may increase the overall cost but also enhance the building's value and functionality.

- Q: How are steel rebars transported to the construction site?

- Various methods are employed for the transportation of steel rebars, also known as reinforcing bars, to construction sites. One commonly used approach involves the use of trucks. The rebars are loaded onto flatbed trucks or trailers and firmly secured with straps or chains to prevent any shifting during transit. These trucks are specially designed to withstand the weight and length of the rebars, boasting robust frames and loading mechanisms. Another method is rail transportation. Steel rebars can be loaded onto rail cars, either on flatcars or in specialized containers, and transported to the construction site. This method proves particularly advantageous for long-distance transportation, as it offers a more cost-effective and efficient solution for large quantities of rebars. For construction projects situated near waterways, the transportation of rebars can also be accomplished by sea or barge. The rebars are loaded onto ships or barges and properly secured to prevent any damage or movement during transit. This method is commonly employed for projects necessitating substantial quantities of rebars or for construction sites located on islands or in coastal areas. Upon arrival at the construction site, cranes or forklifts are typically utilized to unload the steel rebars. These rebars are then either stored in designated areas or immediately employed for reinforcement in the construction process. It is of utmost importance to handle the transportation of rebars with caution, as this ensures their structural integrity and guards against potential accidents or damage during transit.

- Q: What are the advantages of using corrosion-resistant steel rebars?

- The advantages of using corrosion-resistant steel rebars are that they provide increased durability, longer lifespan, reduced maintenance costs, and enhanced structural integrity in reinforced concrete structures.

Send your message to us

Turkish Ukraine HRB400 Dia.16mm Deformed Reinforcement rebar with Price per Ton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords