Solar Mounting System Flat Roof - Triangle Joint Sloped Axis Tracking System for Solar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Triangle joint sloped axis tracking system for solar system

Triangle joint sloped axis tracking system ishigh-tech patented product.

Features:

1. adopt triangle bracket support and framestructure,light weight and easy installation.moving parts used polymer bearingwith self-lubrication and slewing drive with sealing,free of oil andmaintenance free and self-protection from wind and sand.

2. power generating can beincreased by 20-35%.the tracker braket adopt hot-dipped galvanized high-qualitystructural steel Q235B,stainless steel SUS304 and aluminum alloy.

3. working timemore than 25 years.

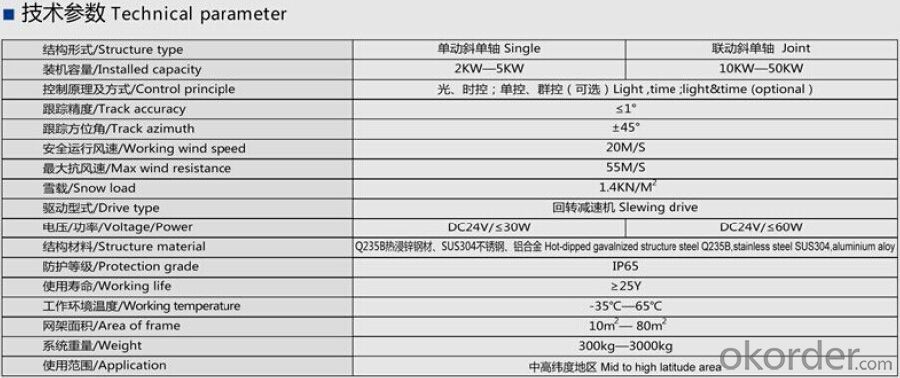

Specification:

•installed capacity | • 1KW—10KW |

•control method | •Light control •time control •light/time control |

•tracking accurancy | • ≤1° |

•Azimuth angle | • ±45° |

•working wind | • 50—70km/h |

•Max wind resistance | • 125—200km/h |

•Driven power | • DC24V/≤30W |

•Structural material | • Q 2 3 5 hot-dip galvanized steel |

•level of protection | • I P 6 5 |

•Quality guarantee | • 25Y/2Y |

•Operating •ambient temperature | • -35℃—65℃ |

•Area of net rack | • 10㎡—80㎡ |

•Unit weight | • 200kg——2000kg |

- Q: What is the expected lifespan of a solar mounting system?

- The expected lifespan of a solar mounting system can vary depending on various factors such as the quality of materials used, installation techniques, and environmental conditions. However, a well-designed and properly installed solar mounting system can typically last for 20 to 30 years or even longer with regular maintenance and inspections.

- Q: What is the expected maintenance cost for a solar mounting system?

- The expected maintenance cost for a solar mounting system can vary depending on various factors such as the type of system, quality of components, installation practices, and local environmental conditions. However, in general, solar mounting systems are designed to be low-maintenance and have minimal ongoing costs. Routine maintenance tasks may include inspecting and cleaning the panels, checking for loose connections or damaged components, and ensuring proper alignment of the system. These tasks can typically be carried out by the system owner or a professional solar installer. Overall, the expected maintenance cost for a solar mounting system is relatively low compared to other renewable energy systems.

- Q: Can a solar mounting system be used in areas with high electricity costs?

- Yes, a solar mounting system can be used in areas with high electricity costs. Installing a solar mounting system allows individuals or businesses to generate their own electricity using sunlight, reducing their reliance on the grid and thus mitigating the impact of high electricity costs. Additionally, solar energy is a renewable and sustainable source, which can provide long-term cost savings and potentially even generate surplus electricity that can be sold back to the grid.

- Q: Can a solar mounting system be installed on a manufacturing or industrial plant?

- Yes, a solar mounting system can be installed on a manufacturing or industrial plant. In fact, many manufacturing and industrial plants are adopting solar energy systems to reduce their carbon footprint and lower their energy costs. These solar mounting systems can be installed on rooftops, parking lots, or even as ground-mounted systems depending on the available space. The installation of solar panels on manufacturing or industrial plants not only helps in generating clean energy but also demonstrates a commitment to sustainability and renewable energy sources.

- Q: Can a solar mounting system be installed on a rooftop with a synthetic roof?

- Yes, a solar mounting system can be installed on a rooftop with a synthetic roof. Synthetic roofs are designed to be durable and capable of supporting the weight of solar panels. However, it is important to consult with a professional installer to ensure that the specific synthetic roof material is compatible with the solar mounting system and to ensure proper installation techniques are followed to avoid any damage to the roof.

- Q: Can a solar mounting system be installed on a university or college campus?

- Yes, a solar mounting system can be installed on a university or college campus. Many educational institutions have embraced renewable energy and are installing solar panels on their campuses to reduce their carbon footprint and promote sustainability. These solar mounting systems can be installed on rooftops, parking structures, or in open areas on the campus grounds.

- Q: Can solar mounting systems be installed on rooftops with skylights?

- Yes, solar mounting systems can be installed on rooftops with skylights. However, careful consideration should be given to the positioning of the solar panels and the skylights to ensure that there is no shading or obstruction of natural light entering the building through the skylights.

- Q: Can a solar mounting system be installed on a desert or arid region?

- Yes, a solar mounting system can be installed on a desert or arid region. In fact, deserts are often considered ideal locations for solar installations due to their high solar irradiance and vast open spaces. However, it is important to consider factors such as extreme temperatures, sandstorms, and dust accumulation, which may require specialized design and maintenance of the mounting system to ensure optimal performance and durability.

- Q: Can a solar mounting system be installed on a rooftop with a dome roof?

- Yes, a solar mounting system can be installed on a rooftop with a dome roof. However, it would require designing and customizing the mounting system to fit the specific shape of the dome roof.

- Q: Are there any specific requirements for installing a solar mounting system?

- Yes, there are specific requirements for installing a solar mounting system. Some of these requirements include ensuring sufficient roof space and orientation for optimal sunlight exposure, structural integrity of the roof to support the weight of the system, compliance with local building codes and regulations, and proper electrical wiring and grounding. Additionally, it is crucial to have a professional installer who is knowledgeable about these requirements and can ensure a safe and efficient installation.

Send your message to us

Solar Mounting System Flat Roof - Triangle Joint Sloped Axis Tracking System for Solar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords