Tray heat shrink packaging machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tray heat shrink packaging machine made in China

Description of Tray heat shrink packaging machine made in China

Packaging machinery refers to machinery that can complete all or part of the product and product packaging process. The packaging process includes major processes such as filling, wrapping, and sealing, as well as related processes such as cleaning, stacking, and disassembling.

In addition, packaging also includes processes such as metering or stamping on packages. The use of mechanical packaging products can increase productivity, reduce labor intensity, adapt to the needs of large-scale production, and meet the requirements of cleanliness and hygiene.

Main Features of Tray heat shrink packaging machine made in China

1. The robot has powerful computing functions and high-precision operations, enabling rapid packing, palletizing and demolition work.

2. In the production line, the robot pallets for packing, palletizing, and demolition work can be flexibly laid out. It is ideal for palletizing at the end of the production line to palletize two or more lines at the same time.

3. The servo motors, programmable controllers, and frequency conversion speed controllers use top quality products to ensure the reliability and long life of the system hardware.

4. High-quality hardware is combined with specialized control software designed by experts to achieve a highly automated system. Perfect safety interlock mechanism can provide protection for equipment and operators.

5. Our superior technology, stable and reliable products and perfect services improve the level of factory automation.

Specifications of Tray heat shrink packaging machine made in China

| Package range | 150g~1000g bagged products |

| Packaging Materials | Paper bag, woven bag (film coating) |

| Arranged form | Double warehouse |

| Compressed air | 0.5 to 0.7MPa Maximum air consumption 0.8 m3/min |

| Power supply | 5Kw 380V±10% 50Hz |

| Packing speed | Large bags of 13 to 40 bags/minute and small bags of 110 to 250 bags/minute; the speed of packaging varies according to the product. In general, granular products are faster than powdery products. Sachets are faster than big bags. |

Applications of Tray heat shrink packaging machine made in China

For mineral water, juice, beverage, liquor, beer, infusion bottles and other product development, speciality, stable performance, product packaging, fastening, beautiful.

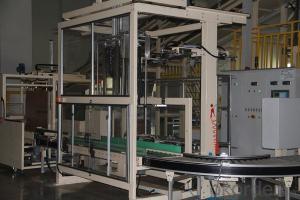

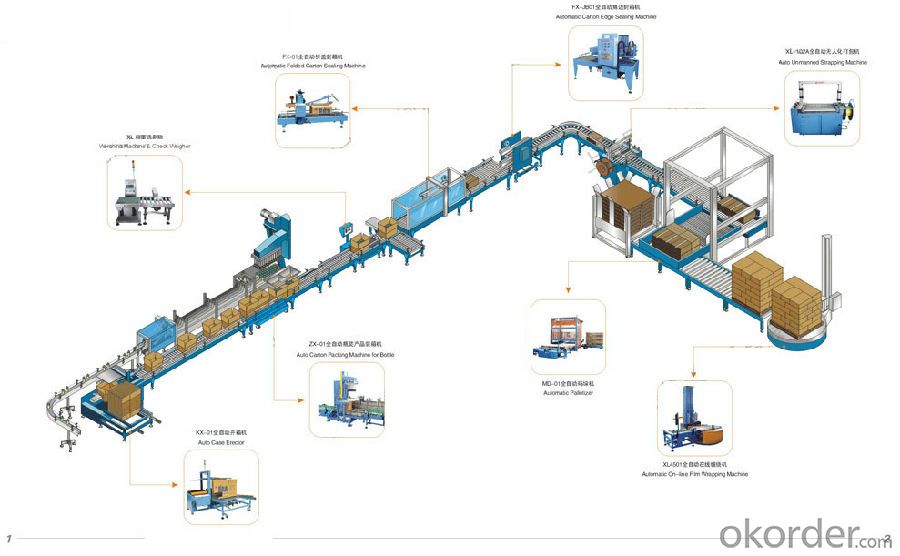

Images of Tray heat shrink packaging machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: What is the general packing cost of beer beverage packaging?

- A privately owned enterprise production and processing, wholesale distribution, production of various types of complete packing machine, sealing machine, packing machine, vacuum machine, sealing machine, electromagnetic machine, packing machine, mushrooms should be material, full automatic filling machine, cuff type packing machine, sending spot

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- This situation is best to find after sale processing, you have difficulty adjusting normal

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

- Q: What is a packaging machine?

- Meet the needs of mass production and meet the requirements of clean sanitationUsually some non-standard equipment, the common is pneumatic and simple combination of electrical components, to meet the requirements of factory automation

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Tray heat shrink packaging machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords