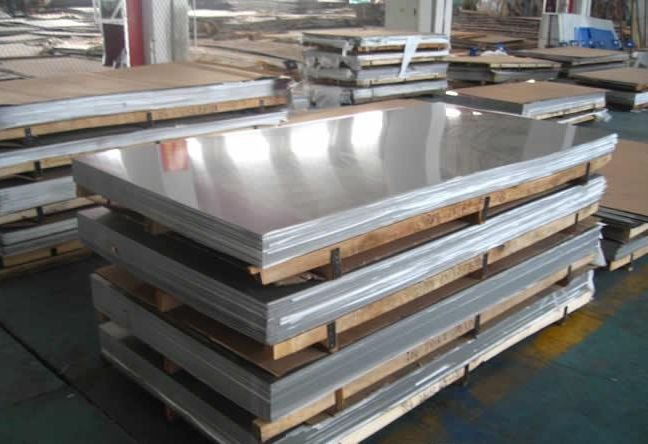

TISCO China 310S Stainless Steel Plate price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| Product: | 310S sheet&plate | |

| Grade: | 304,304L,321,321H,316,316L,317L,310S | |

| Specifications: | Length | 2000-6000mm, or according to customer’s requirement. |

| Width | 32mm-2200mm, or according to customer’s requirement. | |

| Thickness | 0.25-100mm, or according to customer’s requirement. | |

| Standard: | ASTM, GB, JIS, DIN, ASME, etc. | |

| Surface finish: | No. 2B, No. 3, No.4,BA | |

| Application: | construction field, building industry, petroleum & chemical industries, machinary, hardware fields, and so on. | |

| Package detail: | Wraps with kraft paper, steel strip bundled, wooden matting, or as per customers' requirements | |

| Delivery time: | Within 15 days | |

| Payment terms | T/T in advance and the balance by LC | |

| Advantages: | Strong corrosion and decorative effect. | |

| Main product chemical composition |

Grade | C % | Si % | Mn % | P % | S % | Cr % | Mo % | Ni % | Other % |

201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.06 | ≤0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

202 | ≤0.15 | ≤1.00 | 7.5-10.0 | ≤0.06 | ≤0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | - | 6.0-8.0 | - |

302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17-19 | - | 8-10.0 | - |

303 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.2 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | - | 8-10.5 | - |

304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | - | 9-13 | - |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 22-24 | - | 12-15 | - |

310S | ≤0.08 | ≤1.5 | ≤2.00 | ≤0.045 | ≤0.03 | 24-26 | - | 19-22 | - |

316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 10-14 | - |

316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 12-15 | - |

317 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | 3-4 | 11-15 | - |

321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17-19 | - | 9-13 | Ti≥5×C |

430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.04 | ≤0.03 | 16-18 | - | ≤0.6 |

- Q: What's the difference between the 304 stainless steel plate and the 310S stainless steel plate?

- The common marking methods in the field are 0Cr18Ni9, SUS304, in which 06Cr19Ni10 generally means GB standard production, S30408 generally represents ASTM standard production, and SUS 304 represents daily standard production.

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- Stainless steel punching net is a kind of metal plate net made of stainless steel plate punched by punching machine according to certain pass and mould. Common material: stainless steel punching mesh, divided into several materials, there are 201, 304, 321, 316 and 316L.

- Q: How do you remove scratches from stainless steel sheets?

- To remove scratches from stainless steel sheets, there are a few methods you can try. First, you can start by using a non-abrasive cleaner or a mild detergent mixed with warm water. Apply the solution to the scratched area using a soft cloth or sponge, and gently rub in a circular motion. Rinse the area thoroughly and dry it with a clean cloth. If the scratches are still visible, you can try using a stainless steel scratch removal kit. These kits often contain a polishing compound specifically designed for stainless steel. Apply the compound to the scratched area and use a soft cloth to buff the surface in the direction of the grain. Continue buffing until the scratches are no longer visible. For deeper scratches, you may need to use a fine-grit sandpaper or a stainless steel scratch repair pen. Start by lightly sanding the scratched area in the direction of the grain. Be careful not to apply too much pressure, as this can damage the surface. After sanding, clean the area thoroughly and use a polishing compound to restore the shine. It's important to note that these methods may not completely remove deep scratches, and in some cases, a professional repair may be necessary. Additionally, always test any cleaning or repair method on a small, inconspicuous area before applying it to the entire surface to ensure it does not cause further damage.

- Q: Are stainless steel sheets good for cryogenic storage?

- Stainless steel sheets are widely utilized in cryogenic storage owing to their exceptional characteristics. Renowned for its remarkable strength, durability, and corrosion resistance, stainless steel proves to be ideal for extreme temperature settings such as cryogenic storage. Furthermore, stainless steel retains its mechanical properties even under extremely low temperatures, guaranteeing the safety and integrity of stored materials. Moreover, stainless steel sheets exhibit favorable thermal conductivity, enabling efficient heat transfer throughout cryogenic processes. As a result, stainless steel sheets emerge as a dependable option for cryogenic storage purposes.

- Q: What are the color options for stainless steel sheets?

- Stainless steel sheets generally come in a variety of color options, depending on the specific type of finish applied to the surface. The most common color options for stainless steel sheets include silver, which is the natural color of stainless steel, as well as black, gold, bronze, and copper. These colors are achieved through processes such as powder coating, PVD coating, or chemical treatments, which create a thin layer on the surface of the stainless steel sheet. The color options allow for greater versatility in design and can be chosen to complement different aesthetics and applications.

- Q: How do I prevent galvanic corrosion on stainless steel sheets?

- To prevent galvanic corrosion on stainless steel sheets, there are several measures you can take: 1. Ensure proper alloy selection: Choose a grade of stainless steel that is less prone to galvanic corrosion. Grades such as 316 and 317 are more resistant to corrosion compared to 304 stainless steel. 2. Separate dissimilar metals: Avoid direct contact between stainless steel sheets and other metals, especially those with a higher potential for galvanic corrosion. If contact is necessary, use insulating materials such as gaskets or rubber pads to separate the metals. 3. Use protective coatings: Apply protective coatings or paints specifically designed for stainless steel to create a barrier and prevent galvanic corrosion. These coatings act as a sacrificial layer, shielding the stainless steel from direct contact with the corrosive material. 4. Use isolation materials: Install insulating materials between stainless steel sheets and other dissimilar metals. These can include plastic washers, insulating tape, or non-conductive gaskets to prevent direct electrical contact and subsequent corrosion. 5. Proper maintenance: Regularly clean and inspect stainless steel sheets to remove any contaminants or foreign substances that could promote corrosion. Avoid using abrasive cleaners or tools that could damage the protective layer of the stainless steel. 6. Electrochemical protection: Implement cathodic protection techniques, such as using sacrificial anodes or impressed current systems, to provide an external source of electrons that can counteract galvanic corrosion. These methods help shift the corrosion potential of the stainless steel sheets to a more passive range. By following these preventive measures, you can significantly reduce the risk of galvanic corrosion on stainless steel sheets, ensuring their longevity and maintaining their structural integrity.

- Q: What are the different surface textures available for stainless steel sheets?

- There are several different surface textures available for stainless steel sheets, including brushed, mirror, satin, embossed, and patterned.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: Are stainless steel sheets suitable for kitchen countertops?

- Yes, stainless steel sheets are highly suitable for kitchen countertops. They are durable, resistant to stains and corrosion, easy to clean, and provide a sleek and modern look to the kitchen.

- Q: Are stainless steel sheets available in different colors?

- No, stainless steel sheets are typically only available in their natural silver color. Stainless steel is a type of steel alloy that contains chromium, which gives it its characteristic silver appearance. While it is possible to treat stainless steel sheets with various coatings or finishes to achieve a different color, such as black or gold, these are not typically available as standard options. However, there are alternatives like powder coating or painting stainless steel sheets to achieve different colors, but these processes may affect the material's corrosion resistance and durability.

Send your message to us

TISCO China 310S Stainless Steel Plate price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords