310S Stainless Steel Sheet Price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

430 201 304 321 316L 310S 2507 317L 904L 2205 Hard Stainless Steel Sheet Price Per Kg

Type | 430 201 304 321 316L 310S 2507 317L 904L 2205 Hard Stainless Steel Sheet Price Per Kg |

Thinckness | Hot rolled: 3.0mm-20mm |

Widthness | 1000-2000mm or as customized |

Length | 1000mm-6000mm |

Finish | 2B, BA, HL, Mirror, NO1,NO 4, 8K |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS |

Material | mainly:201, 202, 304, 304L, 316, 316L,316 300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,3 200series:201,202,202cu,204 400series:409,409L,410,420,430,431,439 |

Application range | Decoration Industry Kitchenwave Building Elevator Upholstery |

Delivery time | 10-15 days subject to the clients' requirement and quantity |

Productivity | 3000 tons/month |

Note | We can produce other standard as the customers’ requirement |

| Surface | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

| 2B | Those finished, after cold rolling, by heat treatment,pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction,Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size | Building Construction. |

| BA(No.6) | Those processed with bright heat treatment after cold rolling. | Kitchen utensils. Electric equipment,Building construction. |

| Mirror(No.8) | Shinning like a mirror | Building construction |

No. | Grade | Chemical Composition % | ||||||||||

C | Cr | Ni | Mn | P | S | Mo | Si | Cu | N | Other | ||

201 | 1Cr17Mn6Ni5N | ≤0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ≤0.060 | ≤0.030 | - | ≤1.00 | - | ≤0.25 | - |

2205 | 00Cr22Ni5Mo3N,S31803 | ≤0.030 | 21.00-23.00 | 4.50-6.50 | ≤2.00 | ≤0.030 | ≤0.020 | 2.5-3.5 | ≤1.00 | - | 0.08-0.2 | |

202 | 1Cr18Mn8Ni5N | ≤0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ≤0.060 | ≤0.030 | ≤1.00 | - | ≤0.25 | - | |

204 | 03Cr16Mn8Ni2N | ≤0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | 0.15-0.30 | ||||||

301 | 1Cr17Ni7 | ≤0.15 | 16.00-18.00 | 6.00-8.00 | ≤2.00 | ≤0.065 | ≤0.030 | - | ≤1.00 | - | - | - |

304 | 0Cr18Ni9 | ≤0.07 | 17.00-19.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

304L | 00Cr19Ni10 | ≤0.030 | 18.00-20.00 | 8.00-10.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

310S | 0Cr25Ni20 | ≤0.08 | 24.00-26.00 | 19.00-22.00 | ≤2.00 | ≤0.035 | ≤0.030 | - | ≤1.00 | - | - | - |

316 | 0Cr17Ni12Mo2 | ≤0.08 | 16.00-18.50 | 10.00-14.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

316L | 00Cr17Ni14Mo2 | ≤0.030 | 16.00-18.00 | 12.00-15.00 | ≤2.00 | ≤0.035 | ≤0.030 | 2.00-3.00 | ≤1.00 | - | - | - |

431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | ≤0.80 | ≤0.035 | ≤0.030 | - | ≤0.80 | - | - | - |

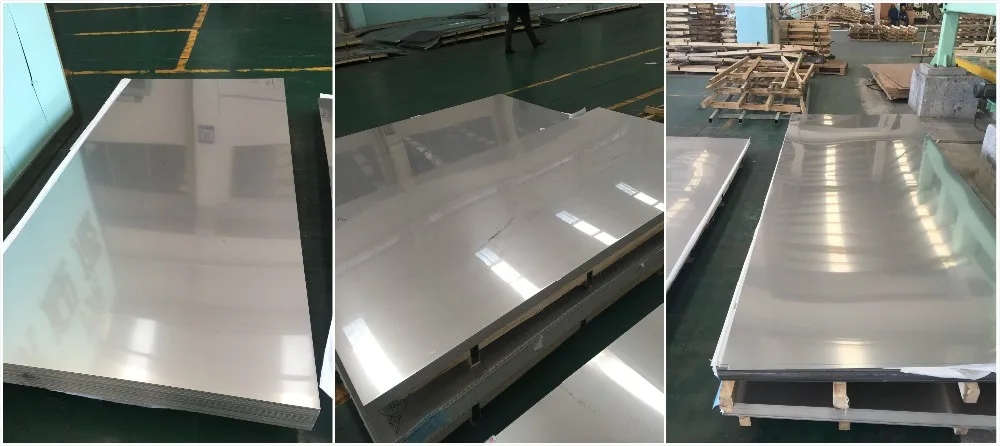

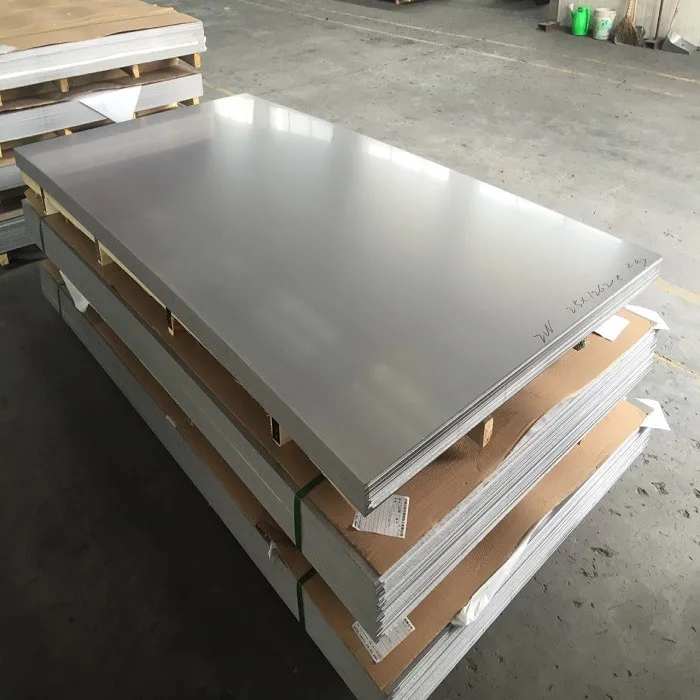

Shows of products

Printing processing

simple process of stainless steel

1.GRINDING

Grinding finish, also called brushed, directional or satin finish. coil or sheet...

2.POLISHING

polished stainless steel sheet uses grinding fluid to polish by polishing equipment on stainless steel ..

3.PVD COLOR COATING

PVD means Physical Vapor Deposition,working in vacuum condiction.....

4.ETCHING

Etching is corrode different kinds of patterns on stainless steel surfaces by chemical methods.

5.EMBOSSING

It is physical rolling on the stainless steel surface, pattern comes from metal roller....

Related Products

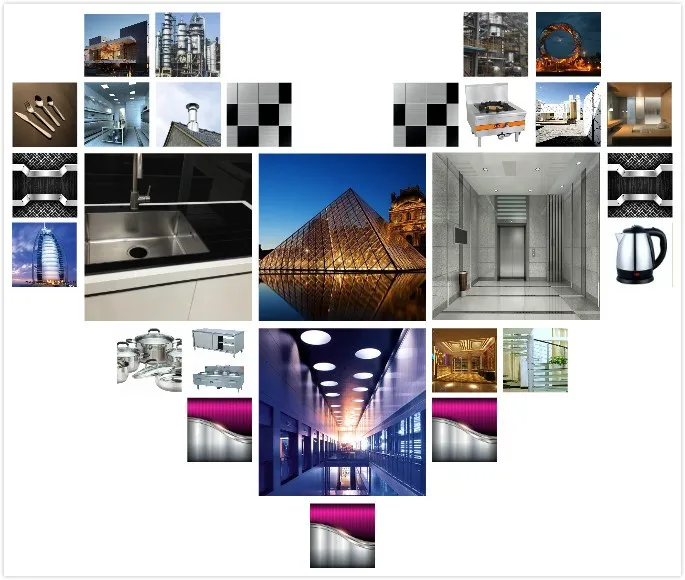

Applications

Stainless steel is widely used such as elevator decoration, luxurious doors, outdoor projects, wall decoration, advertisement nameplates, sanitary ware, ceiling, corridor, hotel hall, shop facade,kitchenware, food industry, electronic industry, medical equipment, etc.

Packaging & Shipping

Standard export package with water proof paper, and metal pallet, and angle bar protection, and steel strip or as required

20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM, 23MTS

40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM, 27MTS

40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM, 27MTS

MOQ | 1 Ton |

Price Term | FOB CIF |

Payment | L/C at sight or 30% TT as deposit |

Delivery Time | 20-30 days after receiving deposit by T/T or L/C. |

Sample | Samples free and express charges bear by you |

- Q: How do you remove rust or corrosion from stainless steel sheets?

- There are several effective methods to remove rust or corrosion from stainless steel sheets. One common approach is to use a mixture of baking soda and water to create a paste, which can be applied to the affected areas and gently scrubbed using a soft cloth or sponge. Another option is to use vinegar or lemon juice, which have natural acidic properties that can help dissolve the rust. Simply soak a cloth in either of the liquids and rub the affected areas until the rust is removed. For more stubborn rust or corrosion, using a commercial stainless steel cleaner or a fine-grit sandpaper can be effective. It is important to always follow the manufacturer's instructions and to test any cleaning method on a small, inconspicuous area before applying it to the entire surface.

- Q: How do I prevent pitting on stainless steel sheets?

- To minimize the occurrence of pitting on stainless steel sheets, there are several steps that can be taken: 1. Opt for the appropriate grade of stainless steel: The resistance to corrosion varies among different grades. It is advisable to select a higher-grade stainless steel, such as 316 or 304, as they offer better protection against pitting. 2. Maintain proper cleaning and upkeep: It is essential to regularly clean the stainless steel sheets using mild soap or a non-abrasive cleaner. Harsh chemicals and abrasive scrubbers should be avoided, as they can scratch the surface and create areas prone to pitting. 3. Prevent exposure to corrosive substances: Shield the stainless steel sheets from extended contact with corrosive substances like saltwater, strong acids, or chlorides. If unavoidable in certain environments, consider applying a protective coating or finish. 4. Control the environment: Ensure that the stainless steel sheets are not exposed to excessive moisture, humidity, or high temperatures. These factors can expedite corrosion and promote pitting. If feasible, store the sheets in a controlled environment with adequate ventilation. 5. Conduct regular inspections and maintenance: Regularly inspect the sheets to detect any signs of pitting or corrosion. If pitting is observed, take immediate action to remove it and prevent further damage. Promptly address any scratches or damages on the surface to prevent the initiation of corrosion. 6. Utilize protective coatings: Consider applying a protective coating or film on the stainless steel sheets. These coatings act as a barrier against corrosive substances and enhance overall resistance to pitting. By adhering to these preventive measures, the risk of pitting on stainless steel sheets can be minimized, ensuring their longevity and durability.

- Q: What are the benefits of using brushed stainless steel sheets in hospitality design?

- Using brushed stainless steel sheets in hospitality design offers several benefits. Firstly, brushed stainless steel has a sleek and modern appearance that adds a touch of elegance to any space, making it a popular choice in the hospitality industry. Additionally, stainless steel is highly durable and resistant to corrosion, ensuring that it can withstand the demands of a busy hospitality environment. It is also easy to clean and maintain, making it a practical choice for surfaces that require frequent sanitation. Furthermore, brushed stainless steel sheets are versatile and can be used in various applications, from countertops and backsplashes to furniture and fixtures, allowing designers to create cohesive and visually appealing spaces.

- Q: What are the benefits of using embossed stainless steel sheets in elevator interiors?

- Embossed stainless steel sheets offer several benefits in elevator interiors. Firstly, they add a touch of elegance and sophistication, enhancing the overall aesthetics of the elevator. Additionally, the embossed pattern provides a unique texture, creating visual interest and making the interior more visually appealing. Moreover, stainless steel is highly durable, resistant to corrosion and staining, ensuring the longevity and easy maintenance of the elevator interior. Lastly, the reflective properties of stainless steel sheets can help to brighten the space, making it feel more open and spacious.

- Q: What are the benefits of using mirror-finish stainless steel sheets?

- There are several benefits to using mirror-finish stainless steel sheets in various applications. Firstly, the mirror-like surface of these sheets adds a touch of elegance and style to any space. Whether it is used in interior design, architecture, or decorative pieces, the reflective nature of the mirror finish enhances the overall aesthetic appeal. Additionally, mirror-finish stainless steel sheets offer exceptional durability and longevity. The high-quality stainless steel material used in their production ensures resistance to corrosion, rust, and staining, making them suitable for both indoor and outdoor use. This quality also makes them easy to clean and maintain, saving time and effort in upkeep. Another advantage of mirror-finish stainless steel sheets is their ability to reflect light. This characteristic makes them an excellent choice for spaces that require enhanced lighting or for applications where light distribution is essential. The reflective surface helps to brighten up the environment, making it ideal for areas such as kitchens, bathrooms, and commercial spaces. Moreover, mirror-finish stainless steel sheets are highly versatile and can be used in a wide range of applications. From countertops and backsplashes in kitchens to wall claddings, elevator interiors, and even custom-made furniture, their versatility allows for creative and unique designs in various industries. Furthermore, mirror-finish stainless steel sheets have excellent heat resistance properties, making them suitable for applications that involve high temperatures. This feature makes them a popular choice in commercial kitchens, industrial settings, and other environments where heat exposure is a concern. Lastly, mirror-finish stainless steel sheets are an environmentally friendly option. Stainless steel is highly recyclable, and using mirror-finish sheets promotes sustainability by reducing the need for new materials. This aspect aligns with the growing emphasis on eco-friendly practices and the desire to reduce the carbon footprint. In conclusion, the benefits of using mirror-finish stainless steel sheets include their elegant appearance, durability, light reflection capabilities, versatility, heat resistance, and eco-friendliness. These qualities make them a desirable choice for various applications, providing both aesthetic appeal and functional advantages.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel is known to have a relatively high electrical resistance compared to other metals. This is due to its composition, which includes a significant amount of chromium and other alloying elements that hinder the flow of electric current. However, the exact value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Therefore, it is crucial to consult the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are several different types of stainless steel sheet embossing patterns available. Some of the most common patterns include: 1. Diamond: This pattern features a series of diamond-shaped indentations evenly spaced across the surface of the sheet. It creates a visually appealing and textured appearance. 2. Linen: The linen pattern resembles the texture of linen fabric, with a series of parallel lines running in one direction and perpendicular lines intersecting them. It adds a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the surface of the sheet. It is commonly used in architectural applications to add visual interest and a tactile feel. 4. Leather: This pattern replicates the texture of leather, with a series of irregular lines and indentations. It provides a unique and luxurious appearance to stainless steel sheets. 5. Hammered: The hammered pattern features a series of irregular indentations that resemble the marks made by a hammer. It adds a rustic and handcrafted look to stainless steel sheets. 6. Checkerboard: This pattern consists of a grid of squares, with alternating squares raised or recessed. It creates a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern features a series of curved lines that resemble ocean waves. It adds a dynamic and flowing look to stainless steel sheets. These are just a few examples of the many different types of stainless steel sheet embossing patterns available. Each pattern can be customized in terms of size, depth, and spacing to suit specific design preferences and applications.

- Q: Are stainless steel sheets good for chemical processing?

- Yes, stainless steel sheets are ideal for chemical processing due to their exceptional corrosion resistance, high strength, and durability. They can withstand exposure to various chemicals, acids, and alkalis without getting corroded or contaminated, making them an excellent choice for such applications.

- Q: Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

- Q: Are stainless steel sheets suitable for cryogenic storage containers?

- Yes, stainless steel sheets are suitable for cryogenic storage containers. Stainless steel is known for its excellent low-temperature properties, making it an ideal choice for cryogenic applications. It has a high resistance to thermal expansion and contraction, making it less prone to cracking or leaking at extremely low temperatures. Additionally, stainless steel is highly durable, corrosion-resistant, and can withstand the extreme conditions of cryogenic storage, ensuring the safety and integrity of the stored materials. Therefore, stainless steel sheets are widely used in the construction of cryogenic storage containers in various industries such as pharmaceuticals, aerospace, and scientific research.

Send your message to us

310S Stainless Steel Sheet Price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords