Tin Free Steel of Prime Quality for Metal Caps or Crowns

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Tin Free Steel of Prime Quality for Metal Caps or Crowns Description

Also known as chromed steel, tin-free steel (TFS) is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.

2.Main Features of the Tin Free Steel of Prime Quality for Metal Caps or Crowns

Chromium coated

Corrosion Resistant

Sulphur Blackening Resistance: TFS has sulphur resistance properties, which can be used for canning protein- rich food such as fish.

Filiform Rust Resistance: Filiform is superficial corrosion of the base metal. TFS has a superior base metal which makes it corrosion resistance.

Paint Adhesion : TFS possesses better paint adhesion properties, thus making it ideal for DRD cans and adhesive bonded cans.

Weldability: TFS can be welded when metallic coating layers are removed by edge grinding.

TFS should be Lacquered / Coated to prevent rust in humid condition.

Internal Coating / Lacquering can be avoided in the case of TFS used to store motor oil or cooking oil.

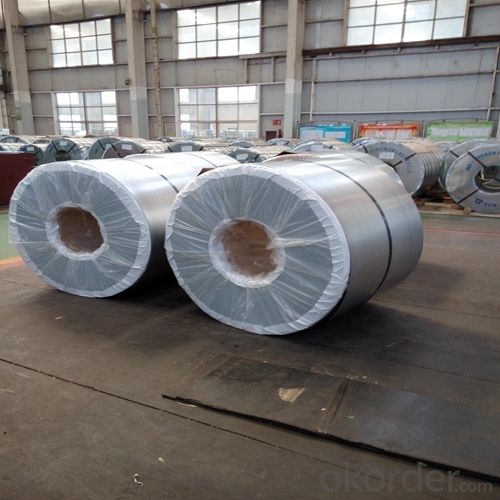

3.Tin Free Steel of Prime Quality for Metal Caps or Crowns Images

4.Tin Free Steel of Prime Quality for Metal Caps or Crowns Specification

Specification of :

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Tin Free Steel of Prime Quality for Metal Caps or Crowns

-What is MOQ?

Our MOQ would be 25 tons.

- Do you only have prime quality TFS ?

We can supply both prime and second quality TFS.

- Q: How thick is tinplate?

- Tinplate typically has a thickness ranging from 0.13 to 0.49 millimeters.

- Q: What are the main applications of tinplate in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for packaging purposes. It serves as a reliable and durable material for manufacturing cans, containers, or closures for various pharmaceutical products. Tinplate provides an effective barrier against moisture, light, and oxygen, helping to preserve the integrity, stability, and shelf life of pharmaceutical drugs. Additionally, tinplate's resistance to corrosion ensures the safety and quality of the packaged medications.

- Q: How does tinplate contribute to the overall portability of packaging?

- Tinplate contributes to the overall portability of packaging by being lightweight and durable, making it easy to transport and handle. It also provides excellent protection against external elements such as moisture, light, and air, ensuring the contents remain intact during transit. Additionally, tinplate's compact and stackable nature allows for efficient storage and maximizes space utilization, further enhancing portability.

- Q: What are the main growth opportunities for the tinplate industry?

- The main growth opportunities for the tinplate industry include the increasing demand for sustainable and eco-friendly packaging solutions, the rapid growth of the food and beverage industry, and the rising popularity of canned products in emerging markets. Additionally, technological advancements in tinplate production and the development of innovative coatings and printing techniques offer opportunities for differentiation and market expansion.

- Q: What are the main applications of tinplate in the marine industry?

- Tinplate is commonly used in the marine industry for various applications including the production of cans and containers for storing food, beverages, and other supplies on ships. It is also utilized for manufacturing components such as panels, fittings, and structural parts due to its corrosion resistance and durability in marine environments. Additionally, tinplate is employed in the construction of ship hulls, bulkheads, and decks, providing protection against rust and enhancing the longevity of marine vessels.

- Q: Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a commonly used material for food packaging due to its durability, corrosion resistance, and ability to protect against light and oxygen. It is also considered safe for food contact and can be easily sterilized, making it suitable for packaging sensitive products like baby food and formula.

- Q: What is the shelf life of tinplate?

- The shelf life of tinplate can vary depending on various factors such as storage conditions and the presence of any protective coatings. However, tinplate typically has a long shelf life, often lasting several years or more if stored properly in a cool, dry place.

- Q: Can you tell me how to deal with the recycling of tinplate?

- General tinplate packaging waste, as long as the rust is not serious, can be converted into hardware products, to achieve the best use of materials. The consumption of tinplate in our country is relatively large (600 thousand tons / year), and 125 tons of tin packing waste can be recovered 1 tons of tin.

- Q: Can tinplate packaging be used for home decor products?

- Yes, tinplate packaging can be used for home decor products. Tinplate is a versatile material that can be easily molded into various shapes and sizes. It provides durability, visual appeal, and can be customized to suit different home decor styles. Additionally, tinplate packaging offers excellent protection for fragile home decor items, making it a suitable choice for packaging and displaying such products.

- Q: How does tinplate impact the ease of opening and closing packaging?

- Tinplate can greatly impact the ease of opening and closing packaging due to its durability and malleability. It provides a sturdy and rigid structure to packaging, ensuring that it maintains its shape and integrity, making it easier to open and close repeatedly without any damage or distortion. Additionally, tinplate's smooth surface allows for effortless sliding and gliding when opening or closing packaging, further enhancing the overall user experience.

Send your message to us

Tin Free Steel of Prime Quality for Metal Caps or Crowns

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords