Three Sides Hot Sealing Laminated Bags For Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Three Sides Hot Sealing Laminated Bags For Packaging:

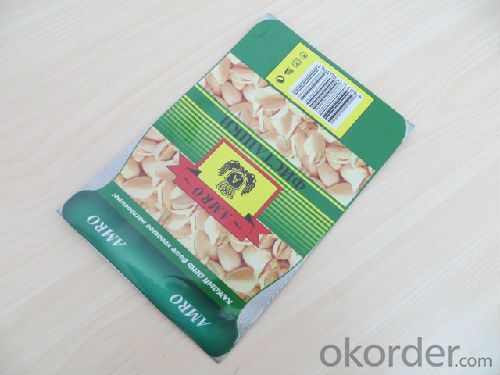

Three Side Hot Sealing Laminated Bags For Packaging are processing with imported materials, we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Three Side Hot Sealing Laminated Bags For Packaging mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Of Three Sides Hot Sealing Laminated Bags For Packaging:

Excellent quality control

Experienced factory produced

SGS passed

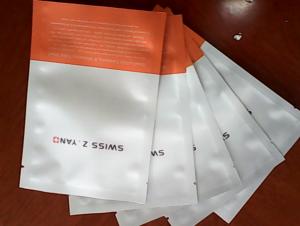

3. Three Side Hot Sealing Laminated Bags For Packaging Photos:

4. Three Side Hot Sealing Laminated Bags For Packaging Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Three Side Hot Sealing Laminated Bags For Packaging:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How do you determine the 210mm*300mm package and determine its version and length?

- Usually 1 meters, or 1 meters, 2 of the lengthWidth 300,3, leave 40 margin, roll on the design length of 940, version 420 weeks, diameter 133.75

- Q: What are the characteristics of a good package?

- According to the statistics of the foreign trade department, because of the backward packaging of export commodities, China has reduced the foreign exchange earnings by at least 10% per year. This shows that the good packaging design for the importance of national economic development.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is low density polyethylene, and PE-LD should be low density polyethylene. Because according to the PE classification, LDPE (low density polyethylene), MDPE (medium density polyethylene), HDPE (high density polyethylene), VLDPE (low density polyethylene), LLDPE (linear low density polyethylene (mPE), metallocene PE). See, "LD" means "low density".

- Q: Why is the higher the elevation, the more food bags inflate? From a physical point of view

- The higher the altitude, the thinner the air outside, the lower the air pressure; and the air pressure inside the food bag is high, which causes the food bag to drum up. As the height gets higher, the air pressure outside may be lower, and food bags are likely to burst because of the pressure inside and outside

- Q: What are the requirements of the gas in the package?

- Some of the most common baked foods, moon cakes, fried foods, potato chips, which are filled with nitrogen, are required to be food grade, high purity, minimum requirement is no harmful gas impurities!

- Q: What about the table of nutrition values on food packages?

- Since each manufacturer may have different sizes of "one", it is better to use 100 grams or 100 milliliter units when comparing the nutrients in a similar product. Quantity of heatHeat is often listed in thousands of joules, and, where possible, the least calorie products should be selected. ProteinIs the total protein content in the food, G is the unit of measurement.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q: How about the material difference of food packaging bag?

- Reason: PE has better heat sealing property, which is easy to sealPA has better printability and is used in the outer layer to print beautiful picturesPVDC EVOH, good separation performance, prevent oxidation. The film closed light is good, not easy to see the light of the product is appropriate.Specific more professional, no longer introduce one by one

- Q: How many kinds of packing bags are there in the packaged foods?

- PE's softness and mechanical properties are worse than those of PP. It represents shopping bags, plastic wrap, garbage bags and so on.PP is stiffer, anisotropic (with a notch that is easily ripped), has good mechanical properties, and is superior to PE in high-temperature performance, representing bread bags.I wonder if this answer has met your requirement.

Send your message to us

Three Sides Hot Sealing Laminated Bags For Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords