Brushed Anodized Thin Aluminum Alloy Sheets for Foil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Thin Aluminum Alloy Sheets used for Foil Stock

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Thin Aluminum Alloy Sheets used for Foil Stock

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Thin Aluminum Alloy Sheets used for Foil Stock

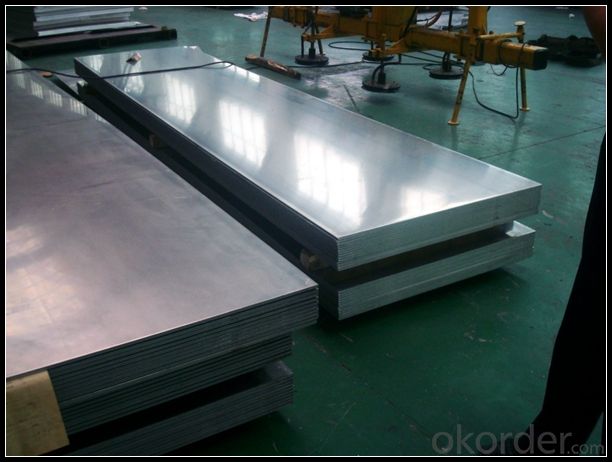

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

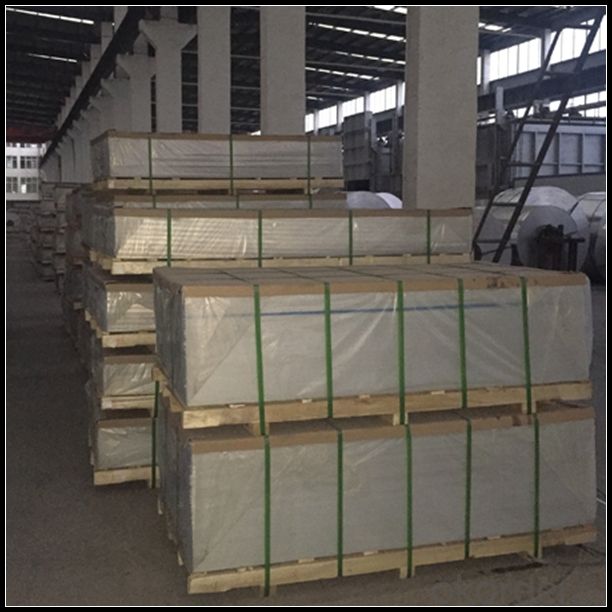

5. Image of Thin Aluminum Alloy Sheets used for Foil Stock

6. Package and shipping of Thin Aluminum Alloy Sheets used for Foil Stock

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean due to their smooth surface and non-porous nature, allowing for easy removal of dirt, grease, and stains with regular cleaning agents.

- Q: What is the price range of aluminum sheets?

- The price range of aluminum sheets can vary depending on various factors such as the size, thickness, and grade of the sheet, as well as the supplier and market conditions. Generally, aluminum sheets can range in price from around $0.50 to $5 per square foot. Thinner sheets or lower-grade aluminum may be on the lower end of the price range, while thicker sheets or higher-grade aluminum can be on the higher end. It is always recommended to compare prices from different suppliers to get the best deal.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered. However, the process for each differs significantly. Welding aluminum typically involves using a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process, which requires a high heat source and a filler material to join the sheets together. The process can be more challenging compared to welding steel due to aluminum's high thermal conductivity and lower melting point. Soldering aluminum, on the other hand, is a process that involves using a low-temperature solder and flux to bond the sheets together. Specialized solders, such as aluminum solder or solder with a high percentage of tin, are typically used. Soldering aluminum is generally less common and more difficult compared to soldering other metals due to aluminum's oxide layer, which can prevent proper adhesion. In summary, while both welding and soldering can be used to join aluminum sheets together, welding is the more commonly used method due to its stronger and more durable results. Soldering aluminum can be more challenging due to the need for specialized solders and the presence of the oxide layer.

- Q: What are the advantages of using 101 aluminum sheets over other materials?

- One advantage of using 101 aluminum sheets is their high strength-to-weight ratio, making them lightweight yet durable. Additionally, aluminum is highly resistant to corrosion, making it suitable for outdoor applications without the need for additional protective coatings. Aluminum sheets are also easy to work with due to their malleability, allowing for various forming and fabrication processes. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: Can aluminum sheet be used in marine environments?

- Yes, aluminum sheet can be used in marine environments. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which helps to prevent further corrosion even in saltwater environments. Additionally, aluminum is lightweight, which makes it an ideal choice for marine applications where weight reduction is crucial. Aluminum sheet is commonly used in boat hulls, decks, and other marine structures due to its durability, strength, and resistance to corrosion.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To determine the thickness tolerance of an aluminum sheet, several factors need to be considered. Firstly, it is important to refer to the industry standards and specifications for aluminum sheets. These standards typically provide guidelines and tolerances for various thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Next, it is crucial to use precise measuring equipment such as calipers or micrometers to accurately measure the thickness of the aluminum sheet. Multiple measurements should be taken at different locations on the sheet to account for any potential variations. Once the measurements are obtained, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance typically represents the acceptable range within which the actual thickness of the sheet can vary. For instance, if the specified thickness tolerance is ±0.002 inches, it means that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is considered to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In some cases, it may be necessary to consult with the manufacturer or supplier of the aluminum sheet to determine the specific tolerance requirements for a particular application. They can provide additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet meets the intended purpose. Overall, determining the thickness tolerance of an aluminum sheet involves following industry standards, using accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This helps ensure that the sheet meets the required specifications and can be used effectively in various applications.

- Q: What is the color range available for aluminum sheets?

- The color range available for aluminum sheets is quite diverse and extensive. Aluminum sheets can be found in a variety of standard colors, including but not limited to silver, black, white, bronze, and gold. Additionally, aluminum sheets can be coated with various finishes, such as anodized, painted, or powder coated, which can further expand the color options. These coatings can provide a wide range of colors, including vibrant shades like red, blue, green, yellow, and more. Furthermore, custom colors can also be achieved through specialized processes, allowing for personalized and unique color choices. Overall, the color range available for aluminum sheets is extensive and flexible, catering to various aesthetic preferences and design requirements.

- Q: How do aluminum sheets perform in terms of thermal conductivity?

- Aluminum sheets are known for their excellent thermal conductivity. They have one of the highest thermal conductivity among common metals, making them highly efficient in transferring heat. This property allows aluminum sheets to quickly absorb and distribute heat, making them ideal for applications where heat needs to be dissipated or transferred rapidly. Additionally, their high thermal conductivity also ensures uniform heat distribution across the surface, minimizing hot spots and enhancing overall heat transfer efficiency. Overall, aluminum sheets are widely recognized for their exceptional thermal conductivity, making them a popular choice in various industries such as automotive, aerospace, and electronics.

Send your message to us

Brushed Anodized Thin Aluminum Alloy Sheets for Foil Stock

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords