Gold Anodized Thick and Thin 5083 Aluminum Sheet for Hot Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Thick and Thin 5083 Aluminum Sheet Description:

5000 series aluminum alloy is a common aluminum alloy series, the main alloy elements are magnesium, the content of magnesium is 3-5%.It's non-Heat treatable aluminum alloy with good corrosion resistance, good machinability, good electric arc welding performance,beautiful surface after anodic treatment.Commonly used in aviation,shipping field,also extensive used in the conventional industry,such as cars,planes,welding pieces,Metro and light rail,need strict fireproof pressure vessel,such as liquid tankers,refrigerated trucks, refrigerated container,refrigeration equipment,television tower,drilling equipment,transportation equipment,missile parts,armor,etc.

Aluminium 5083 is known for exceptional performance in extreme environments. 5083 is highly resistant to attack by both seawater and industrial chemical environments. Alloy 5083 also retains exceptional strength after welding. It has the highest strength of the non-heat treatable alloys but is not recommended for use in temperatures in excess of 65º C

2.Main Features of Thick and Thin 5083 Aluminum Sheet:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

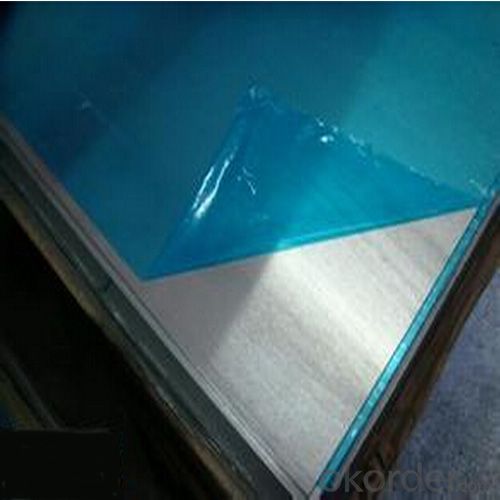

3. Thick and Thin 5083 Aluminum Sheet Images:

4. Thick and Thin 5083 Aluminum Sheet Specification:

Alloy NO. | 1000 series:1050 1060 1070 1100 1200 1235 3000 series:3003 3004 3005 3105 3A21 5000 series:5052 5083 5086 5754 5251 |

Temper | O\H12\H14\H16\H18\H22\H24\H26\H32\H34 |

Specification | thickness:0.15mm-350mm Width:200mm-3000mm |

Surface treatment | coated,polished,embossed, etc |

Colors | Customized |

Features | High weather resistance \anti scratch anticorrosion \ easy processing,installation\ high brightness. |

Application | Construction /Furniture/decorate/industry/cookware/ Roofing sheet/Marine/Fuel tanks/Trailer ,etc. |

Package | Standard seaworthy export packing: wooden pallets with plastics protection |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: What are the distinctions between standard aluminum windows and those that are custom-made?

- <p>Standard aluminum windows are mass-produced and come in set sizes and styles, offering affordability and quick installation. They may not fit perfectly into unique spaces and may lack customization options. Custom-made aluminum windows, on the other hand, are tailored to specific dimensions and design preferences, ensuring a perfect fit and enhanced aesthetics. They often come with more features and options, such as energy efficiency, security, and unique styling, but are typically more expensive and have a longer lead time for production and installation.</p>

- Q: i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- No... all of their computers are made of aluminum (except for the old white macbook) so it'd be kind of hard for them to stop selling aluminum computers. Which one were you looking at? the iMac, mac mini, macbook pro? If you were looking for the regular macbook you probably only saw the plastic white one because as of today, apple decided that the 13inch aluminum unibodies were going to be added to the pro line. They saw a slight spec bump and now come with a new and improved battery and I believe faster processors, but all in all, still the same macbook, just with a new name. Check the macbook pro section.

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to many chemicals. Aluminum has a natural oxide layer on its surface that provides a protective barrier against corrosion and chemical reactions. This oxide layer is stable and resists most acids, alkalis, and organic solvents. However, aluminum can be corroded by certain chemicals, such as strong acids or bases, and some halogenated compounds. Additionally, prolonged exposure to certain chemicals or extreme conditions may weaken the oxide layer and make aluminum more susceptible to corrosion. Therefore, while aluminum sheets are generally resistant to chemicals, it is important to consider the specific chemical environment and potential interactions before using aluminum in certain applications.

- Q: What is the fatigue strength of 101 aluminum sheets?

- The fatigue strength of 101 aluminum sheets refers to the maximum stress level that the sheets can endure without experiencing fatigue failure. The fatigue strength of a material is typically determined through fatigue testing, where the material is subjected to repeated cyclic loading until failure occurs. However, it is important to note that the fatigue strength can vary depending on a range of factors such as the sheet's thickness, surface condition, heat treatment, and other mechanical properties. Therefore, without specific information on these variables, it is not possible to provide an accurate value for the fatigue strength of 101 aluminum sheets. To determine the fatigue strength of 101 aluminum sheets, it is recommended to consult the material's technical datasheet or reach out to the manufacturer or supplier for specific information. They can provide details on the fatigue properties, including the endurance limit or the stress level at which the material can withstand an unlimited number of cycles without fatigue failure.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: Can aluminum sheets be stamped or engraved?

- Aluminum sheets possess the capability to undergo stamping or engraving procedures. Aluminum, being a versatile material, can be easily manipulated through various techniques such as stamping and engraving. Stamping entails the utilization of a stamping machine to press a design or pattern onto the surface of the aluminum sheet. This technique finds extensive usage in industrial settings to generate embossed or raised designs. Conversely, engraving encompasses the act of carving or etching a design onto the aluminum surface using a specialized engraving tool. This method is frequently employed to create intricate and precise designs or to incorporate personalized markings onto aluminum sheets. Both stamping and engraving can be employed on aluminum sheets to accomplish diverse decorative or functional objectives.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Yes, 101 aluminum sheets are generally easy to work with in terms of cutting, drilling, and shaping. Aluminum is known for its lightweight and malleable properties, making it more manageable compared to other metals. The 101 aluminum alloy specifically offers good formability and weldability, making it suitable for various fabrication processes. When it comes to cutting, aluminum sheets can be easily cut using common tools such as a saw, shears, or even a simple utility knife. Similarly, drilling holes in aluminum sheets is relatively easy and can be done with standard drill bits. Lastly, shaping aluminum sheets can be achieved through bending, folding, or using specialized tools like a brake press. However, it's always important to use appropriate safety measures and equipment when working with any metal, including aluminum.

- Q: How do aluminum sheets perform in terms of electrical conductivity?

- Known for their excellent electrical conductivity, aluminum sheets are highly conductive and rank second only to copper among common metals. This exceptional conductivity makes aluminum sheets ideal for a range of electrical applications, including wiring, power transmission, and electrical components. The low resistivity of aluminum enables efficient electricity transfer, leading to minimal energy loss during transmission. Furthermore, the lightweight nature of aluminum sheets makes them a preferred material for electrical systems that prioritize weight reduction. In conclusion, aluminum sheets provide exceptional electrical conductivity and are a reliable and efficient choice for electrical applications.

Send your message to us

Gold Anodized Thick and Thin 5083 Aluminum Sheet for Hot Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords