Tenax Uniaxial Geogrids Fiberglass with Non-Woven Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

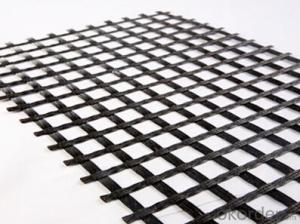

Fibergalss Geogrid Profile

Fiberglass geogrid is a new excellent maeterial used for reinforcing road surface and base, it made by fiberglass filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance, widely used in asphalt road surface, concrete road surface and reinforceing road base.

Main feature of Fiberglass Geogrid with Non Woven Production Line

Fiberglass geogrid is for asphalt road, highway, expressway, strengthen its intension

Main features as the following:

1. High intensity

2. Low elongation

3. Heating stability

4. Easily mixing with asphalt

5. Anti-high temperature

6. Anti-low temperature

Detail Specifications of Fiberglass Geogrid

Specification | 1×1 | 1×1 | 1×1 | 1×1 | 1×1 | 2×2 | 2×2 | |

Strength | Long . Horiz | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 |

≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 | ||

Percentage of Elongation | 4% | 4% | 4% | 4% | 4% | 4% | 4% | |

Size of Hole mm | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 12.7×12.7 | 12.7×12.7 | |

Flexibility | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width M | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | |

Temperature | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | |

FAQ

1. What's the usage of Polypropylene Biaxial geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of Polypropylene Biaxial geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

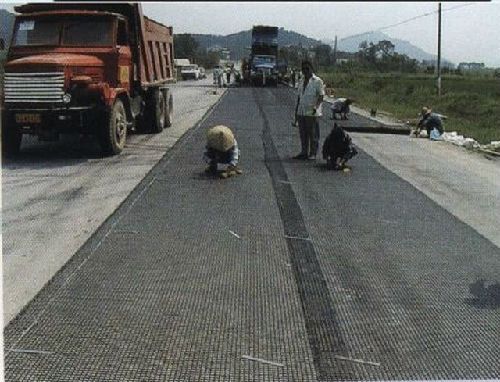

Product Photos

- Q: What are the installation methods for geogrids?

- Geogrids can be installed using various methods such as direct placement, mechanical connection, and soil reinforcement techniques. Direct placement involves laying the geogrid directly on the subgrade or soil surface. Mechanical connection refers to connecting the geogrid to existing structures or other geosynthetic materials using fasteners or anchors. Soil reinforcement methods involve embedding the geogrid within the soil to enhance its tensile strength and stability. The choice of installation method depends on the specific project requirements and the desired outcome.

- Q: How do geogrids help in pavement design?

- Geogrids help in pavement design by providing reinforcement and stabilization to the pavement structure. They distribute the load and improve the overall strength and performance of the pavement, reducing the chances of cracking, rutting, and other forms of distress. Additionally, geogrids enhance the longevity and durability of the pavement, reducing maintenance requirements and costs in the long run.

- Q: What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of the material used in the geogrid, the load applied to the geogrid, the environmental conditions in which the geogrid is placed, and the duration of the load application. Additionally, factors such as installation technique, strain rate, and the presence of moisture can also influence the long-term creep behavior of geogrids.

- Q: Are geogrids resistant to corrosion?

- Yes, geogrids are typically resistant to corrosion. They are made from materials such as high-density polyethylene (HDPE) or polyester, which are not prone to corroding when exposed to moisture or chemical elements. This corrosion resistance makes geogrids suitable for various applications, including soil stabilization, erosion control, and reinforcement in civil engineering projects.

- Q: Can geogrids be used in gabion wall construction?

- Yes, geogrids can be used in gabion wall construction. Geogrids are often used to reinforce the structure of gabion walls, providing additional strength and stability. They are typically placed within the gabion baskets to improve the overall performance and durability of the wall.

- Q: How to ensure the quality of geogrid laying?

- The main role of Geogrid in railway construction in the road surface is the basic links in the whole railway roadbed laying a layer of geogrid can be added to the roadbed closely together, and the geogrid can adapt to a variety of soil environment, can effectively extract high reinforcement bearing surface, occlusal interlocking effect, greatly enhance the bearing capacity of foundation and effectively restrain the soil lateral displacement of reinforced foundation stability performance of geogrid. These performance characteristics make it widely used in the railway. A recent railway department on quality construction of railway engineering construction report disclosed in central and southern Shanxi railway channel

- Q: Are geogrids suitable for stabilizing soft soils?

- Yes, geogrids are suitable for stabilizing soft soils. They are commonly used in geotechnical engineering to enhance the stability and strength of weak or unstable soils. Geogrids provide reinforcement by distributing loads and restricting lateral movement, thereby improving the overall stability of the soil.

- Q: Can geogrids be used in reinforcement of soil-nailing systems?

- Yes, geogrids can be used in reinforcement of soil-nailing systems. Geogrids are commonly used in soil reinforcement applications, including soil-nailing systems, to provide additional stability and strength to the soil. They are typically installed behind the soil nails to distribute the loads and prevent soil movement, enhancing the overall performance of the system.

- Q: Geogrid specification TGSG40-40 what meaning

- I would like to tell you about, TGSG40-40: biaxial tensile plastic geogrid, the vertical and horizontal strength indicators are not less than 40KN, to meet the national standards.

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing typically include several steps and processes to ensure the product meets the required standards and specifications. These measures may include regular inspections and testing of raw materials, such as polymer resins, to ensure their quality and consistency. During the manufacturing process, strict monitoring is carried out to ensure proper mixing and blending of materials, as well as accurate temperature and pressure controls. Additionally, the geogrids are subject to various tests, including tensile strength, elongation, aperture size, and aperture stability tests, to verify their performance and durability. These quality control measures help ensure that the geogrids produced are of high quality and capable of meeting the intended engineering applications.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Tenax Uniaxial Geogrids Fiberglass with Non-Woven Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords