TDS Ellipse Uniform-Thickness Vibrating Screen,Vibration Screen

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

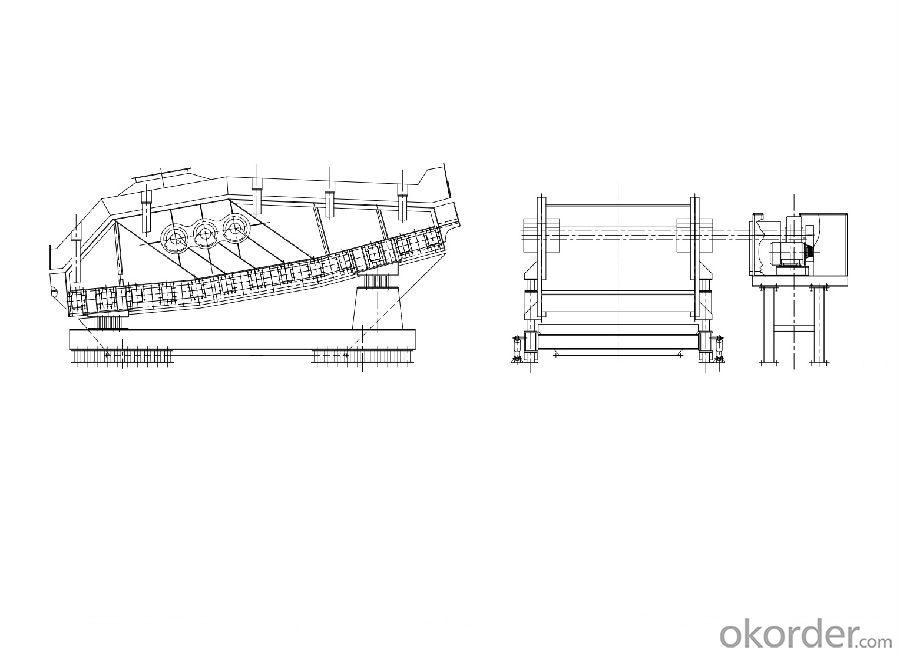

The ellipse uniform-thickness vibrating screen is a kind of vibration screen that it makes a ellipse motion orbit, which has following advantages, such as efficient, high precision of screening and wide applicable and other advantages.

Comparing with the the same specification common screening machine, it has a larger handling capacity and more high-efficiency screening. It is suitable for screening the solvent, sinter in cold condition in metallurgic industry and mineral classification in mine industry, classification, dehydrate and de-medium in mining industry. It is an ideal replaced product to replace present large vibration screen and foreign introduced product.

The ellipse uniform-thickness vibrating screen is mainly made up of straining box, exciter, vibration isolation system, gearing device, deck base with road wheel and other parts. Mostly of the snifter is dual-layer. The structure of the sieve plate is made of cast steel and adopts broach sieve plate. Also, the various sieve plate can be adopted in according to the requirements of the user.

Structural features

It applies the three-phase screen surface design to form the uniform-thickness screening layer.

The materials flow velocity is stable and uniform with high screen efficiency.

It applies three-axis driving and forced synchronous vibration principle to make the stable operation.

There are multiple screen plates for selection.

It is equipped with secondary vibration isolation system to alleviate the foundation load.

The inspection of the screen before the starting:the following items should be inspected.

Firstly, the sanitation should be inspected. Checking all of the connecting bolts to assure whether if they are completed,fastened and intact. Then the exciter should be check to assure that whether if it is intact. Checking the spring vibration aims to assure that whether if there exists no damage, lack, breakage and other phenomenons. Checking the triangular belt aims to assure whether if it is tense and whether if it is in of breakage. Checking the straining box and sieve plate aims to assure whether if it is damaged. Checking the sieve plate aims to assure that whether if it is blocked by the sundries. And the surface of the sifter must be smooth without loose and damaging phenomenon. Checking the inlet and outlet chute aims to assure that whether if it is available. Checking the cross beam aims to assure whether if there exists snap phenomenon. Checking the protective device aims to assure whether if it is reliable and safe. Checking the controlling box, communication and light aim to assure whether if it normal. Checking the ground connection aims to assure that whether if it is reliable and whether if the control buttons are flexible and safe.

Starting: when the vibration screen is started, the operator should stand by the vibration screen to monitor the starting of the machine, which aims to assure whether if there exists abnormal phenomenon. If it does, the machine must be stopped immediately. When the vibration screen is started normally, the operator should patrol all the nozzles on each vibration screen to assure whether whether if it is blocked or it falls off. The operator should often check the the temperature, sound of the machine and vibrator. Observing the vibrated condition aims to assure whether if the vibration in four corners are in the same frequency and whether if there exists coal leakage and loose triangular belt phenomenon. Always, the effectiveness of dehydrate and de-medium. Checking the condition of the inlet and outlet phenomenon of screen aims to assure whether if it is blocked or normal.

Halting:after all of the materials in the screen have been ejected, the vibration screen can be halted. The operator should observe the screen to check whether if it will clash with other equipment when it go through the point of resonance during halting. When it happens, the machine should be halted immediately. When the machine will jeopard the safety of the operator and machine, or the the area of the screen is stacked with much sundries,or the feeding is not successful, or the screen is damaged serious, or the chute under the screen is blocked seriously, or the straining box shakes violently and or abnormal phenomenons, the fault should be excluded firstly and then restart the system of vibration screen.

Technical specification

Model | Screen surface area | Classification point | Amplitude | Vibration time | Handling capacity | Power | Inclination angle on the screen surface | |||

㎡ | Mm | Long axis | Minor axis | r/min | t/h | Kw | Head | Central | Tail | |

TDS3690 | 32.4 | 5-20 | 8-10 | 3-5 | 800 | 400-950 | 2×55 | 15 | 10 | 5 |

TDS3090 | 27 | 5-20 | 8-10 | 3-5 | 800 | 300-800 | 2×45 | 15 | 10 | 5 |

TDS3075 | 22.5 | 5-20 | 8-10 | 3-5 | 850 | 300-600 | 2×30 | 30 | 20 | 10 |

TDS2575 | 18.75 | 5-20 | 8-10 | 3-5 | 800 | 200-500 | 2×30 | 15 | 10 | 5 |

TDS2460 | 14.4 | 5-20 | 8-10 | 3-5 | 850 | 150-300 | 2×15 | 30 | 20 | 10 |

TDS2060 | 12 | 5 | 10-15 | 4-6 | 850 | 150-200 | 2×15 | 15 | 10 | 5 |

The foregoing attached table shall only be used for reference. The actual application shall be appropriately modified according to customers requirements.

FAQ:

What’s the meaning of the ellipse uniform-thickness in the ellipse uniform-thickness vibrating screen?

Ellipse means that the ellipse uniform-thickness vibrating screen adopts three sets of vibrator devices. The material in the ellipse uniform-thickness vibrating screen will make a ellipse motion. Thus, it is named as ellipse vibrating screen. Why it is named as uniform thickness is that each zone for stacking the materials has the same thickness. It can be called as the the same thick material layer. This model has the highest screening efficient by vibration. It has the greatest performance.

What pattern do the scale board adopt?

There exists various models can the scale board adopt, such as molten plate, PU plate and wear-resisting steel plate.

Generally, what type do the vibrator adopt?

The vibrator will adopt box-type vibrator, which is convenient to maintain and install.

- Q: How many screens of vibrating screen is better?

- This depends on the requirements of your screening materials, if it is to remove impurities, and with a layer of screen can be, and that is the best, if it is used for grading, it depends on how many points you have,

- Q: What does the model of linear vibrating screen mean?

- The running track of the linear vibrating screen is straight, and the YK series vibrating screen is a circular vibrating screen, and the running track is straight

- Q: ZKR type of linear vibrating screen

- ZKR series vibrating screens are suitable for coal, water power, mines, building materials, chemicals and other industries. The DZSF type linear vibrating screen is the principle of double vibration motor drive and vibration motor vibration excitation. The utility model has the advantages of high screening accuracy, large processing capacity, simple structure, good tightness, convenient maintenance and automatic operation in assembly line production. It is suitable for screening of any dry material of size 0.74-10mm, water content less than 7% and non sticky material. Widely used in abrasives, chemical raw materials, plastics, medicine, resin powder, ceramic raw materials, metallurgy, building materials, food, food, chemical and other industries in the dry powder, fine granular or fine powder materials screening.

- Q: Vibration exciter of linear vibrating screen

- Choose a linear vibrating screen, you can go to Nanchang Yangtze River CISCO mining machinery official website to understand, there should be the vibration screen you want.

- Q: How to solve the problem of vibrating screen clay?

- Vibration screen: vibrating screen is the use of vibrator excitation vibration generated by reciprocating spiral vibration and work. The upper rotating heavy hammer of the vibrator causes the screen surface to produce a plane whirling vibration, while the lower rotating heavy hammer causes the screen surface to have a conical rotary vibration, and the combined action of the rotating heavy hammer causes the screen surface to generate a complex rotary vibration. The vibration trajectory is a complex space curve. The curve is projected on the horizontal surface into a circle, and the projection on the vertical surface is an ellipse. Adjusting the exciting force of the upper and lower rotating weights can change the amplitude. While adjusting the spatial phase angle of the upper and lower heavy weights, the curve shape of the screen surface movement track can be changed, and the movement track of the material on the screen surface can be changed.

- Q: How does a feed vibrating screen work?

- Feed screening, it is necessary to choose a linear vibrating screen and the like,The effect of the linear vibrating screen in removing impurities is better, and it can be used safely

- Q: What are the reasons for the small amount of circular vibrating screen?

- Check the wiring mode, whether the line meets the reverse

- Q: Is Derek's high frequency vibrating screen the same as an ordinary high frequency vibrating screen?

- Dissimilarity。 In principle, a good separation condition is achieved by using high frequency and low amplitude, so that smaller than the size of the separation of particles, especially larger than the particles and pulp, through the sieve hole to become the product of the screen. But Derek high frequency vibrating screen structure adopts a layered structure, realizes the multi-channel parallel feeding at the same time, it not only has the advantages of high processing capacity, high screening efficiency, and screening machine occupies little space classification size can reach 300 orders, to choose the design process, is one of the most widely used equipment and tailings slurry the process of ore dressing plant. And with a high wear-resistant polyurethane screen, not only has high porosity and long screen life, is 10~15 times of ordinary screen, these advantages are Derek high frequency vibrating screen is widely used in mineral processing technology. However, imported products will be relatively high prices, the current domestic products have similar products can replace imports.

- Q: What is the required opening rate of the vibrating screen?

- You mean screen or something?. In fact, each kind of vibrating screen is different, each has its advantages and disadvantages. You can search Xinxiang for major materials introduction.

- Q: Working principle of scree vibrating screen?

- You can use the stone mine linear vibrating screen, the principle of work is: two motor synchronous reverse placed to generate reverse exciter exciting force, forcing the mesh sieve body driven to do the vertical movement, the material on the exciting force and periodic thrown forward in a range, thus completing the material screening operation. Beijing Yan Sen Tengda vibration screening equipment production. You can contact us by telephone or visit the company website for details of the product

Send your message to us

TDS Ellipse Uniform-Thickness Vibrating Screen,Vibration Screen

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords