Steel Deformed Rebar In Coil Small Sizes for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Deformed Rebar In Coil Small Sizes for Construction Description:

Steel deformed rebar in coil small sizes for construction is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel deformed rebar in coil small sizes for construction is usually made of structural steel and is used in construction and civil engineering. The steel deformed rebar in coil small sizes for construction resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel deformed rebar in coil small sizes for construction theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Deformed Rebar In Coil Small Sizes for Construction:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

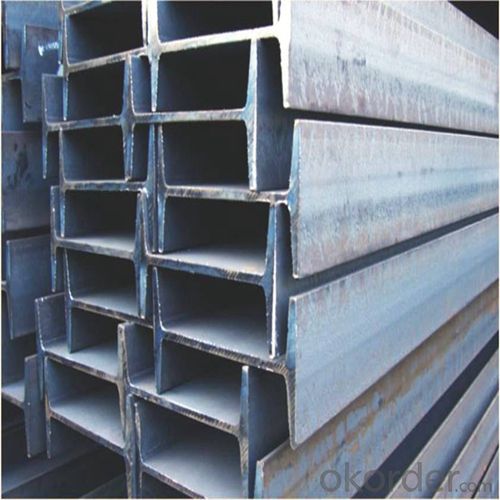

3. Steel Deformed Rebar In Coil Small Sizes for Construction Images:

4. Steel Deformed Rebar In Coil Small Sizes for Construction Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How are steel rebars protected during the concrete pouring process?

- During the concrete pouring process, steel rebars are protected in several ways to ensure their longevity and structural integrity. Firstly, before the concrete is poured, the rebars are carefully cleaned to remove any rust, dirt, or other contaminants that could compromise the bond between the rebar and the concrete. This is typically done by using a wire brush or other mechanical means. Once the rebars are cleaned, they are usually coated with a protective layer or coating. One common method is to apply an epoxy coating to the rebars. This coating acts as a barrier, preventing moisture and chemicals from reaching the steel and causing corrosion. Epoxy coatings are often used in high-risk environments such as marine structures or areas with high chloride content. Another method of protection involves using corrosion inhibitors. These inhibitors are added to the concrete mix, which then forms a protective layer around the rebars. The inhibitors work by reducing the corrosive effects of chloride ions, oxygen, and other chemicals that could lead to corrosion. Additionally, during the pouring process, it is important to ensure proper concrete cover over the rebars. Concrete cover refers to the thickness of the concrete layer between the surface and the rebar. Adequate concrete cover helps protect the rebars from exposure to moisture, chemicals, and other environmental factors. To achieve the required concrete cover, steel stirrups or spacers are placed around the rebars to maintain a specific distance between the rebar and the formwork. This ensures that the concrete is evenly distributed around the rebars, providing them with the necessary protection. In summary, steel rebars are protected during the concrete pouring process through various methods such as cleaning, applying protective coatings, using corrosion inhibitors, and maintaining proper concrete cover. These measures help to prevent corrosion and ensure the durability and strength of the reinforced concrete structure.

- Q:How do steel rebars affect the overall crack resistance of concrete structures?

- Steel rebars play a crucial role in enhancing the crack resistance of concrete structures. When embedded within the concrete, rebars provide reinforcement and increase the tensile strength of the structure. Concrete is inherently strong in compression but weak in tension, and steel rebars help overcome this weakness by absorbing the tensile forces that may cause cracks in the concrete. The presence of rebars in concrete structures allows for the redistribution of stress, preventing cracks from propagating and spreading. As the concrete undergoes shrinkage or experiences external loads, the rebars act as a reinforcement grid and help to resist the formation and expansion of cracks. By absorbing and distributing the tensile stresses, rebars ensure that the concrete remains intact and can withstand higher loads without significant cracking. Moreover, steel rebars also contribute to the overall durability of concrete structures. When corrosion of the rebars occurs due to exposure to moisture or other environmental factors, it can lead to an increase in volume, causing internal pressure and potential cracking of the concrete. However, the use of corrosion-resistant rebars, such as epoxy-coated or stainless steel rebars, can significantly mitigate this risk and improve the crack resistance of the structure. In summary, steel rebars enhance the crack resistance of concrete structures by providing reinforcement, increasing tensile strength, redistributing stress, and preventing crack propagation. Their presence ensures that the structure can withstand various types of loads and environmental conditions, improving both the strength and durability of the concrete.

- Q:Can steel rebars be used in retrofitting existing structures?

- Yes, steel rebars can be used in retrofitting existing structures. They are commonly employed to enhance the strength and stability of buildings, bridges, and other infrastructure. By reinforcing the existing concrete or masonry elements, steel rebars help improve their load-carrying capacity and resistance to various forces, such as seismic activity or increased loads. This makes them an ideal choice for retrofitting projects, ensuring the safety and longevity of existing structures.

- Q:What is the impact of moisture on steel rebars?

- Moisture can have a detrimental impact on steel rebars as it promotes corrosion and rust formation. When moisture comes into contact with steel rebars, it creates an electrochemical reaction that leads to the formation of rust. This process weakens the steel, reduces its load-bearing capacity, and compromises the structural integrity of the reinforced concrete. Over time, the expansion of rust can cause cracks and spalling in the surrounding concrete, further accelerating the deterioration of the rebar and potentially causing structural failure. To prevent these issues, proper measures such as adequate concrete cover, waterproofing, and regular maintenance should be implemented to minimize the exposure of rebars to moisture.

- Q:What are the guidelines for protecting steel rebars during concrete placement and compaction?

- The guidelines for protecting steel rebars during concrete placement and compaction are essential to ensure the structural integrity and durability of the concrete structure. Here are some key guidelines to follow: 1. Covering and Support: Steel rebars should be adequately covered and supported to protect them from corrosion and damage. The minimum cover requirements should be met as specified in the design or relevant standards. The rebars should be positioned accurately and must not touch the ground or formwork directly. 2. Cleanliness: Before placing concrete, the rebars should be thoroughly cleaned to remove any rust, scale, dirt, or other contaminants. This can be achieved by wire brushing, sandblasting, or using other appropriate methods. Clean rebars provide a better bond with the concrete and reduce the risk of corrosion. 3. Moisture Control: The rebars should be kept dry during concrete placement and compaction. Excessive moisture can accelerate corrosion, especially in areas with high humidity or chloride exposure. Proper drainage systems and the use of waterproofing membranes can help prevent moisture accumulation. 4. Spacing and Tying: Rebars should be adequately spaced and tied together to maintain the desired concrete cover and prevent displacement during concrete placement and compaction. This ensures that the rebars are properly embedded in the concrete and provide the required structural strength. 5. Vibrating and Compaction: During concrete placement, care should be taken to prevent direct contact between the vibrator and the rebars, as this can cause damage or displacement. Vibrating should be done carefully and gradually, ensuring that the concrete is compacted uniformly and tightly around the rebars. 6. Concrete Placement Techniques: Proper concrete placement techniques should be followed to minimize the risk of rebar displacement. The concrete should be placed gently and evenly, avoiding excessive dropping or splashing that could displace the rebars. Proper compaction and consolidation techniques should also be employed to eliminate voids and ensure full encapsulation of the rebars. 7. Protection from External Factors: The rebars should be protected from environmental factors that can cause corrosion, such as exposure to moisture, chemicals, or aggressive soils. Adequate curing of the concrete is crucial to prevent rapid drying or carbonation, which can lead to corrosion and reduced durability. By following these guidelines, the rebars can be effectively protected during concrete placement and compaction, ensuring the longevity and safety of the concrete structure. It is recommended to consult the relevant design codes, specifications, and industry best practices for specific guidelines applicable to the project at hand.

- Q:Can steel rebars be used in the construction of residential communities?

- Yes, steel rebars can be used in the construction of residential communities. Steel rebars provide strength and durability to reinforced concrete structures, making them suitable for a wide range of construction projects, including residential buildings. The use of steel rebars helps ensure the structural integrity and longevity of the buildings, making them a reliable choice for residential communities.

- Q:What are the factors that determine the spacing and diameter of steel rebars?

- The factors that determine the spacing and diameter of steel rebars include the structural design requirements, the load and stress distribution within the concrete structure, the type and size of the structure being reinforced, and the concrete's strength and durability requirements. Additionally, local building codes and regulations may also influence the spacing and diameter of steel rebars.

- Q:Can steel rebars be used in heritage building restoration?

- Yes, steel rebars can be used in heritage building restoration. They are commonly used to reinforce and strengthen the structural integrity of old buildings, helping to preserve their historical significance and ensure their longevity.

- Q:Can steel rebars be used in cold weather conditions?

- Yes, steel rebars can be used in cold weather conditions. Steel has excellent cold weather performance and can maintain its structural integrity even in extremely low temperatures. However, it is important to ensure that proper construction practices are followed, such as protecting the rebars from moisture and using appropriate concrete curing methods to prevent freezing and cracking.

- Q:Can steel rebars be used in solar power plant construction?

- Yes, steel rebars can be used in solar power plant construction. Steel rebars are commonly used as reinforcement in concrete structures, including the foundations and structural components of solar power plants. They provide strength, durability, and stability to the construction, ensuring the long-term performance and safety of the solar power plant.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Deformed Rebar In Coil Small Sizes for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords