Steel coil AZ50 aluzinc 0.17~4.0mm galvalume coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Galvalume should not be used on, in, or around concrete or mortar. Concrete and mortar are highly

alkaline environments. Bare Galvalume and painted Galvalume sheets suffer rapid corrosion when

in contact with mortar and concrete. Bare Galvanized and painted Galvanized perform better in this

type of environment.

While Galvalume has excellent durability in many settings, it should not be used adjacent to concrete or mortar.

Due to the high alkaline content in these environments, bare and painted Galvalume rapidly corrode.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

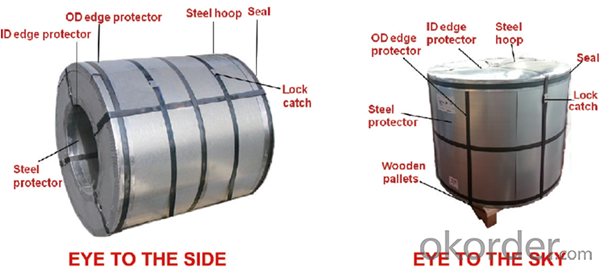

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties through a combination of destructive and non-destructive testing methods. Destructive methods involve conducting tensile, hardness, and impact tests on samples taken from the coils. Non-destructive methods, such as ultrasonic or magnetic particle testing, are also employed to detect surface and internal defects without damaging the coils. These inspections ensure that the steel coils meet the required mechanical specifications for their intended applications.

- Q: How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems to create various components such as gears, shafts, and bearings. These coils are often transformed into flat sheets or strips, which are then shaped and processed to form the required parts. The strength and durability of steel make it an ideal material for transmission systems as it can withstand the high stress and torque associated with transmitting power from the engine to the wheels efficiently and reliably.

- Q: How do steel coils contribute to the circular economy?

- The recyclability and reusability of steel coils make them valuable contributors to the circular economy. The main goal of the circular economy is to minimize waste and promote the continuous use of resources, and steel coils align perfectly with this concept. To begin with, steel coils are manufactured using recycled steel, which reduces the need for extracting raw materials and the associated negative environmental effects. By utilizing recycled steel, we can conserve natural resources and decrease energy consumption in the manufacturing process. This practice not only lowers carbon emissions but also decreases the overall ecological footprint. Furthermore, steel coils can be easily recycled once they reach the end of their lifespan. Steel has one of the highest recycling rates globally. When the coils are no longer in use, they can be collected, processed, and transformed into new steel products without losing their properties or quality. This closed-loop recycling system ensures that steel resources are continuously utilized, reducing the need for virgin steel production. In addition, steel coils support the circular economy by enabling the production of durable and long-lasting products. Steel is renowned for its strength and durability, making it ideal for various applications such as construction, automotive, and packaging. By using steel coils, we can manufacture products with extended lifespans, minimizing the need for frequent replacements and reducing waste generation. Moreover, steel coils can be reused multiple times before being recycled. They can be rewound, reshaped, or repurposed for different applications, thus extending their lifecycle and reducing the demand for new coils. This aspect of reusability contributes to resource efficiency and waste reduction. To summarize, steel coils play a significant role in the circular economy by being made from recycled steel, easily recyclable themselves, enabling the production of durable products, and promoting reuse. Their contribution helps close the loop in the steel industry, conserves natural resources, reduces waste generation, and minimizes environmental impact.

- Q: steel structure

- Disadvantages Of Steel

- Q: Can steel coils be coated with aluminum?

- Yes, steel coils can be coated with aluminum. This process is commonly known as the coil coating or the prepainting process, where a layer of aluminum is applied onto the steel coils to enhance their corrosion resistance and improve their aesthetic appearance.

- Q: the comparison needed between other steel

- *Mild steel is ductile and can be easily machined. Generation of heat is less than that of steel machining.So, the tool can have better life and you can do more machining. Cost factor is of prime importance as other steel are more costly than Mild steel. Mild steel, a grade of steel that does not harden when heated and chilled with cold water, so further machining can be easy. Mild steel is easily available.You will find it in your scrape yard. No need to change the tool repeatedly and no special tools are required for machining. Above is the comparisation between alloy steel,SS and superalloys. Cutting speed and feed does not required special skills.

- Q: I want an EDC (Every Day Carry) Knife that:~folds~is non-serrated~has a pocket clip~has a blade length of about 4 in. long~is concealable~urban environment friendly~priced around $50What do you suggest? I am currently thinking on purchasing the Cold Steel 4 inch Zytel Ti-Lite.

- Based okorder /

- Q: How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as the primary material for producing pipes and tubing. These coils are processed and formed into various shapes and sizes to create the necessary components, such as the main exhaust pipe and smaller sections for mufflers and catalytic converters. The steel's strength and durability make it an ideal choice for withstanding the high temperatures and corrosive nature of exhaust gases, ensuring the longevity and functionality of the system.

- Q: What are the common problems encountered with steel coils during production?

- Some common problems encountered with steel coils during production include surface defects such as scratches, rust, and scale formation, dimensional deviations, coil breaks or tears, edge defects, and coil slippage. Other issues may include coil handling and storage problems, coil winding or coiling defects, and quality control problems such as inconsistent chemical composition or mechanical properties.

- Q: Does aluminum or steel hold up better? We found a steel for 1/2 the price of aluminum, obviously its heavier but any other downsides? rust faster ect? also, does anybody know, in PA do you pay sales tax on trailers? and do dealers normally give you license plates to get the trailer home with? we live 3 hours away from the dealer so thats why i want all details :) would stink if i messed up!!

- We have an aluminum trailer over a steel frame. We used to have a steel trailer. There are two differences I see are the weight and how quickly they deteriorate. I personally prefer the aluminum over the steel, the upkeep is easier and they don't weigh as much which equates to fuel savings. Also if you have a lighter truck an aluminum trailer makes the wear and tear a little easier. You can also look at the size of the truck you are going to tow the trailer with, and the size of the horses inside. All together you definately don't want to exceed the weight limits of the truck. Hope this helps...

Send your message to us

Steel coil AZ50 aluzinc 0.17~4.0mm galvalume coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords