Biodegradable Geotextile Fabric - Staple Fibers Punched Non Woven Geotextile Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

Staple fibers needle punched non woven geotextile is made of PP or PET staple fibers on carding cross- laying equipment and needle punched equipment.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Properties of Staple fibers needle punched non woven geotextile

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

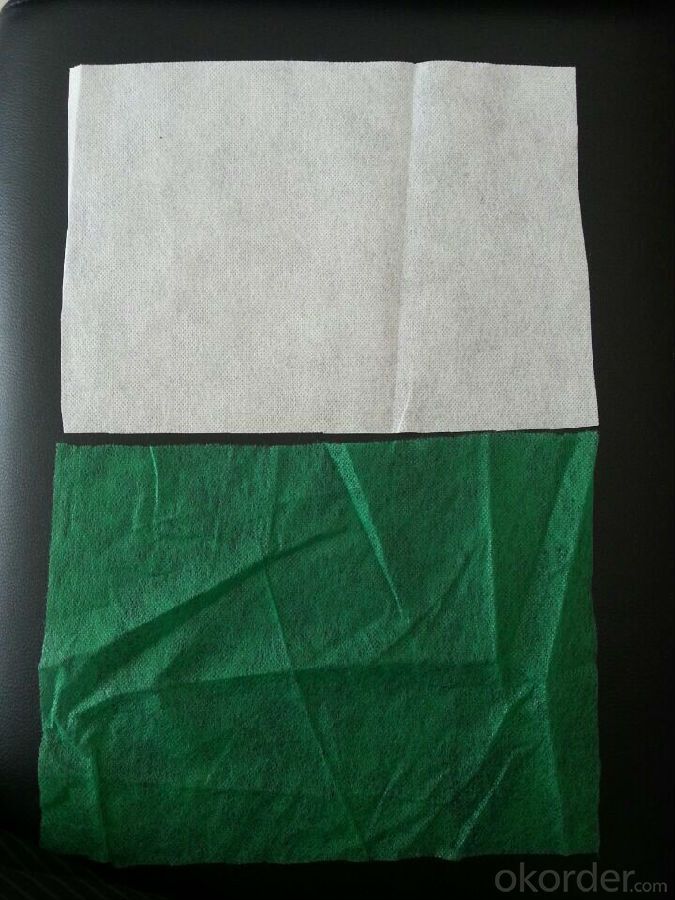

Images of non woven geotextile

- Q: Geotextile geotextile geotextile construction geotextile specific application

- Geotextile in the construction of the main building is to protect the concrete: 1, in the summer construction of geotextile is to protect the concrete in the water; 2, in the winter construction of geotextile that can protect the concrete moisture also play a role in insulation.

- Q: Textile geotextile lap length how much

- Lap width is generally 10-15cm

- Q: What are the different geotextile manufacturing processes?

- There are several different geotextile manufacturing processes, including needle punching, thermal bonding, spunbonding, and weaving. Each process has its own advantages and is used depending on the desired properties and applications of the geotextile. Needle punching involves mechanically interlocking fibers, thermal bonding uses heat to bond fibers together, spunbonding creates a nonwoven fabric through extrusion and stretching, and weaving involves interlacing yarns to create a fabric. These processes allow for the production of geotextiles with various strengths, permeabilities, and filtration capabilities, making them suitable for a wide range of civil engineering and environmental applications.

- Q: How do geotextiles help in preventing sinkhole formation?

- Geotextiles help in preventing sinkhole formation by providing a stable base for the soil and reducing the risk of erosion. They act as a barrier to prevent the movement of soil particles, thus preventing the formation of voids or cavities that can lead to sinkholes. Additionally, geotextiles can improve the overall structural integrity of the soil, enhancing its load-bearing capacity and minimizing the potential for sinkhole development.

- Q: This is a large sample of gravel anti-filter how this project count

- Visual inspection of the slope of the distance from the clay layer is equal to the thickness of the gravel layer, that is 200mm, so even if it came out scattered Simple function. Also, I used a simple method is to draw in CAD, fill, measure the area, area by length, the volume came out

- Q: What are the maintenance requirements for geotextile installations?

- The maintenance requirements for geotextile installations typically involve regular inspections to ensure proper functioning and longevity. This may include removing any accumulated debris or sediment that could hinder its performance, checking for any signs of damage or wear, and addressing any issues promptly to prevent further deterioration. Additionally, periodic testing and evaluation of the geotextile's performance may be necessary to ensure it is meeting the desired objectives.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavier materials like rocks or concrete. This results in reduced labor and transportation costs. Secondly, geotextiles offer excellent filtration and drainage properties, allowing water to pass through while preventing the migration of fine particles. This helps in stabilizing the soil and preventing erosion, which is particularly beneficial in areas prone to heavy rainfall or water runoff. Additionally, geotextiles provide increased strength and reinforcement to the soil, enhancing overall stability and load-bearing capacity. This is especially useful in areas with weak or unstable soils, where traditional materials may not provide adequate support. Furthermore, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring long-term durability and reducing the need for frequent maintenance or replacement. Overall, the use of geotextiles in construction offers cost-effective, sustainable, and versatile solutions for various soil-related challenges, providing numerous advantages over traditional construction materials.

- Q: Polyester filament nonwoven is filament geotextile

- Yes, generally do geotextile material, polyester filament nonwoven fabric refers to filament geotextile. Huazhi geotechnical materials manufacturers to answer your questions

- Q: Can geotextiles be used in the protection of underground tanks?

- Yes, geotextiles can be used in the protection of underground tanks. Geotextiles are often used as a protective layer in tank installations to prevent damage from sharp objects, provide a barrier against soil contaminants, and help with drainage and filtration.

- Q: What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

Send your message to us

Biodegradable Geotextile Fabric - Staple Fibers Punched Non Woven Geotextile Direct Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords