Stainless Steel Sheets Per Ton Price in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

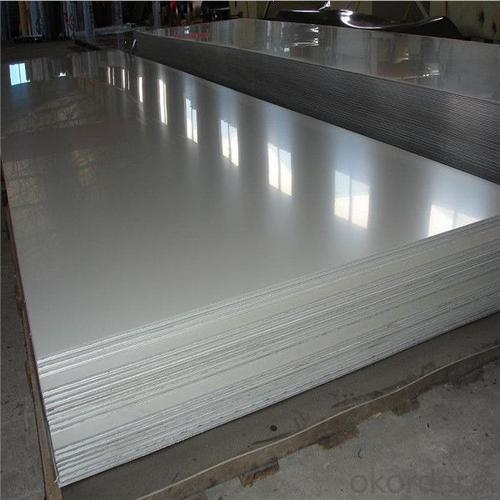

Stainless Steel Sheets Per Ton Price in China

Features Stainless Steel Sheets Per Ton Price in China:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information Stainless Steel Sheets Per Ton Price in China:

1. Steel grade: 321,304,316l

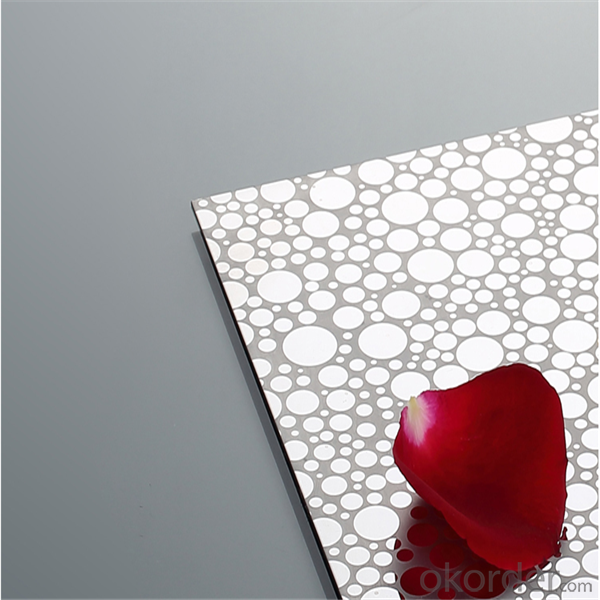

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6 Supplier Product Code: SDJM

7. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

| Commodity | Stainless Steel Sheets Per Ton Price in China | |||||||

| Thickness | 0.3 mm-120mm | |||||||

| Width | 500mm, 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm, etc | |||||||

| Length | 1000mm-6000mm or as customer request | |||||||

| Standard | AISI, ASTM, EN, BS, SUS, DIN, JIS, etc | |||||||

| Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 410S, etc | |||||||

| Surface | 2B, BA, HL, 8K, No. 4, etc | |||||||

| Brand name | TISCO, LISCO, JISCO, ZPSS, BAOSTEEL, etc | |||||||

| Packaging | Standard export sea-worthy packing | |||||||

| Technique | Hot rolled / cold rolled | |||||||

| Delivery time | Within 7-10 days after receive your desipot | |||||||

| Supply ability | 500 metric tons/ week | |||||||

| Certification: | ISO9001: 2008 | |||||||

| Payment terms | 30% T/T as deposit and the balance should be paid by L/C or against copy of B/L | |||||||

| Applications | 201 Stainless Steel hot rolled plate applies to construction field, ships building industry, petroleum and chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. | |||||||

| Advantages | Strong corrosion and decorative effect; Excellent and high quality control; competitive price; Timely, reliable and efficient delivery; Customer service. Cheap, better, faster | |||||||

| Note | We can produce other standard as the customers' requirement | |||||||

- Q: Can stainless steel sheets be used for elevator doors or panels?

- Yes, stainless steel sheets can be used for elevator doors or panels. Stainless steel is a popular choice for elevator applications due to its durability, corrosion resistance, and sleek appearance. It provides a clean and modern look, making it a suitable material for elevator doors or panels.

- Q: How do you prevent scratching on stainless steel sheets during handling and installation?

- To avoid scratching stainless steel sheets while handling and installing them, there are several precautions you can take: 1. Apply protective covering: Prior to handling or installation, it is advisable to apply a protective film or covering on the surface of the stainless steel sheets. This covering acts as a barrier, safeguarding against scratches and scuff marks during transportation and installation. It is important to ensure that the chosen covering is suitable for stainless steel and leaves no residue when removed. 2. Handle with caution: It is crucial to be mindful of how you handle the stainless steel sheets. Avoid dragging or sliding them against rough surfaces or each other, as this can result in scratches. Instead, use appropriate lifting techniques and handle the sheets with clean, dry hands or gloves to minimize the risk of leaving marks. 3. Utilize suitable tools: When working with stainless steel sheets, ensure that you use tools specifically designed for this purpose. Refrain from using tools with rough or abrasive surfaces that could potentially scratch the stainless steel. Opt for tools made from soft materials or those with protective coatings to reduce the chances of surface damage. 4. Keep work areas clean: Before installing stainless steel sheets, it is essential to ensure that the work area is clean and free from any debris or particles that could potentially scratch the surface. Use a clean cloth or soft brush to wipe down the area, removing any dirt, dust, or loose materials that could cause scratches during the installation process. 5. Secure sheets during transportation: If you need to transport stainless steel sheets, it is crucial to secure them properly to prevent any movement or shifting that could lead to scratches. Utilize appropriate packaging materials such as foam inserts, edge protectors, or straps to keep the sheets in place and minimize the risk of damage. By adhering to these preventive measures, you can significantly reduce the likelihood of scratching stainless steel sheets during handling and installation, ensuring a flawless finish and preserving the quality of the material.

- Q: What are the advantages of using stainless steel sheets?

- Using stainless steel sheets in various applications offers several benefits. First and foremost, stainless steel is renowned for its outstanding resistance to corrosion. It is highly effective in preventing rust and stains, making it an ideal option for environments where moisture and corrosive substances are present. This exceptional durability ensures that stainless steel sheets maintain their aesthetic appeal and structural integrity over time. Furthermore, stainless steel is exceptionally strong and durable. It possesses a high tensile strength, enabling it to withstand heavy loads and resist deformation. This makes stainless steel sheets perfect for applications that require robustness, such as construction, automotive, and industrial projects. Additionally, stainless steel is sanitary and easy to clean. Its non-porous surface prevents the growth of bacteria and other microorganisms, making it a popular choice for food processing equipment, medical tools, and healthcare facilities. Moreover, stainless steel sheets are simple to maintain, as they can be easily wiped clean or sterilized without causing any damage to the material. Moreover, stainless steel sheets offer both versatility and aesthetic appeal. They feature a sleek and modern appearance that can enhance the visual appeal of architectural designs, interior decorations, and kitchen appliances. With a variety of finishes available, including brushed, mirror, or textured, stainless steel sheets can be customized to suit specific design preferences. Lastly, stainless steel is an environmentally friendly material. It is 100% recyclable, meaning it can be reused and repurposed without any loss in quality or performance. This makes stainless steel sheets a sustainable choice, reducing the necessity for new raw materials and minimizing waste. In conclusion, the benefits of using stainless steel sheets include exceptional corrosion resistance, strength and durability, hygienic properties, aesthetic appeal, and environmental sustainability. These characteristics make stainless steel sheets a versatile and dependable choice for a wide range of applications.

- Q: Are stainless steel sheets resistant to saltwater?

- Yes, stainless steel sheets are resistant to saltwater. Stainless steel is known for its corrosion resistance, and it is particularly well-suited for environments with high levels of saltwater exposure. The chromium content in stainless steel forms a protective layer on the surface of the metal, preventing rust and corrosion. This makes stainless steel sheets an excellent choice for applications in marine environments, such as boat construction, offshore structures, and coastal infrastructure. Additionally, stainless steel's resistance to saltwater also makes it suitable for other applications like coastal architecture, kitchen equipment, and medical instruments.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are indeed suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity, which allows for efficient heat transfer. It also has high corrosion resistance and can withstand high temperatures, making it a reliable choice for various heat transfer applications.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Yes, stainless steel sheets can be used in the aerospace industry. Stainless steel possesses excellent strength, corrosion resistance, and high-temperature stability, making it suitable for various aerospace applications such as aircraft frames, engine components, and structural parts.

- Q: Are stainless steel sheets suitable for elevator flooring?

- Yes, stainless steel sheets are suitable for elevator flooring. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for high-traffic areas like elevator floors. It can withstand heavy loads and is resistant to scratches, stains, and dents, ensuring a long-lasting and aesthetically pleasing flooring option. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for elevator flooring.

- Q: Can stainless steel sheets be used for elevator cabs?

- Yes, stainless steel sheets can be used for elevator cabs. Stainless steel is a popular material choice for elevator cabs due to its durability, resistance to corrosion, and aesthetic appeal. It provides a sleek and modern look, making it a desirable option for both commercial and residential elevators. Stainless steel sheets can be easily fabricated and customized to fit the specific dimensions and design requirements of an elevator cab. Additionally, stainless steel is easy to clean and maintain, which is important for high-traffic areas like elevators. Overall, stainless steel sheets are a suitable and reliable choice for elevator cabs.

- Q: Can stainless steel sheets be used for railway station facades?

- Railway station facades can indeed utilize stainless steel sheets. These sheets are made from a resilient and corrosion-resistant material, capable of enduring severe weather conditions. As a result, they are well-suited for outdoor applications. Moreover, stainless steel boasts an appealing and contemporary look, making it highly favored in architectural design. Its ease of cleaning and maintenance is also noteworthy, particularly in heavily trafficked zones such as railway stations. All in all, stainless steel sheets prove to be a fitting and pragmatic choice for railway station facades.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

Send your message to us

Stainless Steel Sheets Per Ton Price in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords