Stainless Steel Sheet AISI 420 with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate::

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions.

Festures of stainless steel plate:

architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building, decorated inside the train, as well as outdoor works, advertising nameplate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place,kitchen equipment,light industrial and others.

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | product parts manufacturing and stainless steel products tooling and so on |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. |

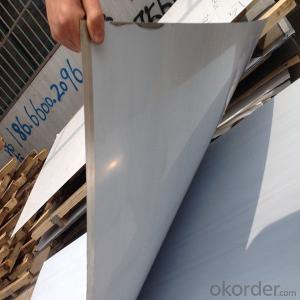

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How is steel wire rod used in the manufacturing of suspension wires for bridges?

- Steel wire rod is used in the manufacturing of suspension wires for bridges by being drawn and processed into high strength steel cables. These cables are then used to support the weight of the bridge, providing stability and strength to withstand the loads and forces acting upon it.

- Q: How is steel wire rod used in the production of wire mesh for erosion control?

- Steel wire rod is an essential component in the production of wire mesh for erosion control. The wire rod is first passed through a series of machines to undergo a process called wire drawing, where it is stretched to a smaller diameter and shaped into a long, continuous wire. This wire is then further processed to achieve the desired thickness and strength required for erosion control applications. In the production of wire mesh for erosion control, the steel wire rod is typically woven or welded together to create a mesh structure. The wire mesh acts as a physical barrier to prevent soil erosion by holding the soil in place, especially on sloping terrain or areas prone to water flow. The wire rod's high tensile strength and durability make it an ideal material for erosion control applications. The wire mesh produced from steel wire rod is capable of withstanding harsh environmental conditions, such as heavy rainfall or strong water currents, without deforming or breaking. The wire mesh can be tailored to specific erosion control needs by adjusting the gauge and spacing of the wires. Thicker wires and smaller spacing are used for applications that require higher strength and stability, such as retaining walls or embankments. On the other hand, thinner wires and wider spacing may be suitable for less demanding erosion control situations, such as stabilizing soil on residential properties or landscaping projects. Overall, the use of steel wire rod in the production of wire mesh for erosion control provides a reliable and long-lasting solution to prevent soil erosion. Its versatility allows for customization based on specific project requirements, ensuring effective erosion control measures are implemented in various applications.

- Q: How is steel wire rod used in the production of wire ropes for elevators?

- Steel wire rod is used as the raw material in the production of wire ropes for elevators. It is first hot rolled into long, thin rods, and then further processed and drawn into the desired diameter and strength. These steel wire rods provide the necessary strength and durability to the wire ropes, ensuring their safe and reliable operation in elevator systems.

- Q: What are the different types of steel wire rod finishes?

- There are several different types of steel wire rod finishes, each designed to provide specific properties and functionalities. Some of the most common types include: 1. Black finish: This is a basic, untreated finish that leaves the steel wire rod with a dark, black color. It provides minimal protection against corrosion, but is commonly used in non-structural applications where aesthetics are not a concern. 2. Galvanized finish: This finish involves coating the steel wire rod with a layer of zinc to protect against corrosion. The zinc coating provides excellent resistance to rust and is commonly used in outdoor applications or in environments where the wire rod may be exposed to moisture. 3. Coated finish: Steel wire rods can also be coated with various materials, such as PVC or nylon, to provide additional protection against corrosion and abrasion. These coatings can also offer improved electrical insulation properties or better grip for specific applications. 4. Stainless steel finish: Stainless steel wire rods are made from an alloy that contains a high percentage of chromium, which provides excellent resistance to corrosion. This finish is commonly used in applications where hygiene, durability, and corrosion resistance are important, such as in the food industry or medical field. 5. Bright finish: This finish involves a mechanical or chemical process that removes any surface impurities or oxidation, leaving the steel wire rod with a smooth, shiny appearance. Bright finishes are often used in decorative applications or where an aesthetically pleasing appearance is desired. 6. Phosphated finish: Phosphating is a chemical process that creates a layer of phosphate coating on the steel wire rod's surface. This finish enhances the wire rod's corrosion resistance and improves its paint adhesion, making it suitable for applications where painting or further coating is required. These are just a few examples of the different types of steel wire rod finishes available. The choice of finish depends on the specific application requirements, such as corrosion resistance, aesthetics, or functional properties needed.

- Q: What are the applications of steel wire rods?

- Due to their strength, flexibility, and durability, steel wire rods find wide-ranging applications across various industries. Examples of their common uses include: 1. Construction: The construction industry heavily relies on steel wire rods to reinforce concrete structures. They are employed to create steel mesh, stirrups, and rebar, significantly enhancing the strength and stability of buildings, bridges, and other infrastructure. 2. Automotive sector: The automotive industry considers steel wire rods indispensable. They are employed to manufacture springs, suspension systems, tire reinforcement, and seat frames, providing the necessary strength and resilience for various automotive components. 3. Manufacturing: Steel wire rods are utilized in the manufacturing of a diverse range of products such as nails, screws, bolts, and wire mesh. These products serve applications in the construction industry, furniture manufacturing, and general fabrication processes. 4. Electrical industry: The electrical industry employs steel wire rods in cable and conductor production. They form the core of electrical cables, ensuring efficient electricity transmission over long distances. 5. Agricultural sector: Steel wire rods are used in the agricultural sector for fencing and animal enclosures. They provide a strong and durable barrier, ensuring the security and safety of livestock and crops. 6. Packaging industry: The packaging industry utilizes steel wire rods to produce wire-based packaging materials like wire baskets, racks, and crates. These products offer a sturdy and reliable solution for transporting and storing various goods. 7. Wire products: Steel wire rods are also transformed into a wide array of wire products, including wire ropes, springs, piano wires, and welding electrodes. These products cater to diverse industries such as mining, marine, manufacturing, and construction. In conclusion, steel wire rods have vast and diverse applications, spanning across construction, automotive, manufacturing, and electrical industries. Their strength, flexibility, and durability make them indispensable, playing a crucial role in enhancing the performance and reliability of various products and structures.

- Q: What are the common production processes for low carbon steel wire rod?

- The common production processes for low carbon steel wire rod include melting and refining the raw materials, continuous casting to form billets, hot rolling the billets into wire rod coils, cooling and coiling the wire rod, and finally, surface treatment and packaging for shipment.

- Q: What are the main factors influencing the choice of steel wire rod order lead time?

- The main factors influencing the choice of steel wire rod order lead time are demand and supply dynamics, production capacity, transportation logistics, and customer requirements. Firstly, demand and supply dynamics play a significant role in determining the lead time for steel wire rod orders. If there is high demand for steel wire rod products, manufacturers may have longer lead times due to increased production requirements and limited availability of raw materials. Conversely, during periods of low demand, lead times may be shorter as manufacturers can allocate resources more efficiently. Production capacity is another crucial factor. The lead time for steel wire rod orders depends on the production capacity of the manufacturer. If a manufacturer has limited production capacity, it may take longer to fulfill orders, resulting in longer lead times. On the other hand, manufacturers with larger production capacities can process orders more quickly, leading to shorter lead times. Transportation logistics also influence the choice of lead time for steel wire rod orders. If the manufacturer is located far from the customer or if there are logistical challenges, such as limited transportation options or customs clearance delays, the lead time may be longer. Efficient transportation networks and streamlined logistics processes can help reduce lead times. Additionally, customer requirements play a role in determining the lead time for steel wire rod orders. Some customers may have specific delivery deadlines or urgent requirements that need to be met. In such cases, manufacturers may prioritize these orders and provide shorter lead times to ensure customer satisfaction. Conversely, if customers have more flexible timelines, manufacturers may allocate resources to orders with shorter lead times. In conclusion, the main factors influencing the choice of steel wire rod order lead time include demand and supply dynamics, production capacity, transportation logistics, and customer requirements. Manufacturers need to consider these factors to determine an appropriate lead time that balances customer needs with operational capabilities.

- Q: How is steel wire rod used in the production of wire mesh baskets for industrial applications?

- The production of wire mesh baskets for industrial applications heavily relies on steel wire rod. This rod acts as the main raw material for creating the wire mesh. To manufacture the wire mesh baskets, the steel wire rod undergoes a process called wire drawing. This process involves passing the rod through a series of dies to decrease its diameter and increase its length. As a result, a long and continuous wire is formed, which is thinner and more flexible than the original rod. The drawn wire is then woven into a mesh pattern using a machine. This weaving process creates a flexible and sturdy structure, with the size of the mesh varying based on the specific requirements of the application. Once the wire mesh is formed, it is usually cut into the desired shape and size to create the basket. The wire mesh can be easily manipulated and bent into different configurations, making it perfect for constructing baskets with specific dimensions and designs. The choice of steel wire rod in the production of wire mesh baskets is justified by its high strength and durability. Industrial applications often demand baskets capable of withstanding heavy loads or harsh environments, and steel wire provides the necessary strength and resilience. Additionally, the wire mesh structure allows for excellent visibility and airflow, making it suitable for various industrial purposes such as storage, transportation, and handling of goods. It offers secure containment while facilitating easy inspection and ventilation. In conclusion, steel wire rod plays a vital role in the production of wire mesh baskets for industrial applications. Its versatility, strength, and durability make it an ideal choice for creating baskets that can endure demanding conditions and effectively store and transport goods.

- Q: What are the different types of steel wire rod packaging options after wire drawing?

- After wire drawing, there are several packaging options available for steel wire rods. These options are designed to protect the wire rods during storage, transportation, and handling. The different types of steel wire rod packaging options include: 1. Coils: Steel wire rods can be packaged in the form of coils. The wire is wound around a cylindrical core, creating a compact and secure package. Coils are widely used for packaging steel wire rods, as they are easy to handle, stack, and transport. They are commonly available in different sizes, ranging from small coils for lightweight wire rods to larger coils for heavier gauge wire rods. 2. Spools: Spools are another popular packaging option for steel wire rods. The wire is wound around a spool, which provides a more organized and controlled arrangement. Spools are commonly used for smaller diameter wire rods, especially in industries where precision and ease of use are important, such as electrical and electronics industries. 3. Straight bars: In some cases, steel wire rods are packaged as straight bars. This packaging option is suitable for wire rods with larger diameters and lengths. Straight bars are often used in industries where the wire rods are further processed or cut into specific lengths for various applications. 4. Bundles: Steel wire rods can also be packaged in bundles. Bundles are created by tying together multiple wire rods using straps or wires. This packaging option is commonly used for longer wire rods that cannot be coiled or spooled. Bundles provide stability and protection to the wire rods during transportation and storage. 5. Pallets: Pallets are used to package wire rods in bulk quantities. The wire rods are stacked and secured on wooden or plastic pallets, ensuring easy handling and efficient storage. Pallets are commonly used for larger wire rod shipments, allowing forklifts or pallet jacks to move and transport the wire rods easily. 6. Containers: For international shipments or long-distance transportation, steel wire rods can be packaged in containers. Containers provide a secure and protected environment for wire rods, preventing damage from moisture, dust, or other external factors during transit. It is important to select the appropriate packaging option based on the size, weight, and specific requirements of the steel wire rods. Proper packaging ensures the integrity and quality of the wire rods, minimizing the risk of damage and facilitating efficient handling and transportation.

- Q: How is the fatigue resistance of steel wire rod tested?

- The fatigue resistance of steel wire rod is typically tested using a cyclic fatigue test. This involves subjecting the wire rod to repeated loading and unloading cycles until it fails. The number of cycles required to cause failure, as well as any changes in the wire rod's mechanical properties during the test, are measured and analyzed to determine its fatigue resistance.

Send your message to us

Stainless Steel Sheet AISI 420 with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords