Carbon Steel Hot Rolled Wire Rod with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Wire Rod are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Carbon Steel Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

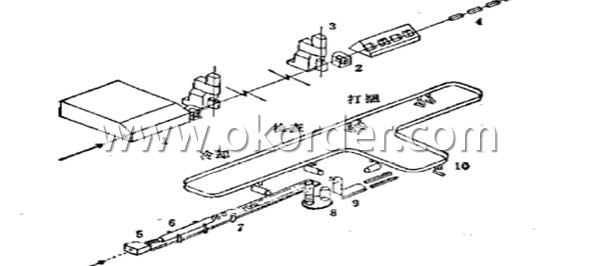

Production Process of Wire Rod

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Image

- Q: How is steel wire rod used in the manufacturing of wire baskets and containers?

- Steel wire rod is used in the manufacturing of wire baskets and containers as the primary raw material. It is first drawn through a series of dies to achieve the desired diameter and shape. This process strengthens the wire and improves its structural integrity. The wire rod is then bent, welded, or woven into the desired basket or container shape, providing a sturdy and durable framework. Additionally, the steel wire rod can be coated or galvanized to enhance its corrosion resistance, ensuring a longer lifespan for the wire baskets and containers.

- Q: How is steel wire rod used in the manufacturing of wire forms for ski lifts?

- Steel wire rod is an essential component in the manufacturing of wire forms for ski lifts. These wire forms are responsible for providing the necessary support and strength to the ski lift system. Firstly, steel wire rod is used to create the primary cables that run along the ski lift structure. These cables bear the weight of the ski lift and its passengers, ensuring their safety and stability. The high tensile strength of steel wire rod is crucial in withstanding the heavy loads and stress that the ski lift system experiences during operation. Additionally, steel wire rod is utilized in the creation of the suspension cables that connect the ski lift cabins to the primary cables. These suspension cables play a vital role in keeping the cabins balanced and levelled while in motion. The durability and reliability of steel wire rod ensure that these suspension cables can withstand the constant movement and varying forces exerted on them. Moreover, steel wire rod is also used in the construction of safety cables that are installed as a precautionary measure. These safety cables act as a backup system, providing an additional level of security for the ski lift passengers. In case of any unforeseen event or malfunction, the safety cables ensure that the cabins remain securely attached to the primary cables, preventing any potential accidents. Overall, steel wire rod serves as the backbone of wire forms for ski lifts by providing the necessary strength, stability, and safety required for their operation. The quality and durability of steel wire rod play a crucial role in ensuring the reliability and longevity of ski lift systems, ultimately contributing to the safety and enjoyment of skiers and snowboarders.

- Q: What are the common applications of pre-stressed and oil tempered steel wire rod?

- Pre-stressed steel wire rod is commonly used in construction and engineering applications, such as for pre-tensioning or post-tensioning of concrete structures, bridges, and high-rise buildings. It helps to improve the load-bearing capacity, durability, and overall structural integrity of these projects. On the other hand, oil tempered steel wire rod is frequently utilized in the manufacturing of springs, suspension systems, and other high-stress applications. Its unique properties, obtained through the tempering process, provide excellent resistance to fatigue and ensure reliable performance in demanding industries such as automotive, aerospace, and machinery.

- Q: What are the different surface defects that can affect the magnetic properties of steel wire rod?

- Some common surface defects that can affect the magnetic properties of steel wire rod include surface roughness, scale formation, decarburization, and surface contamination. These defects can disrupt the magnetic domain alignment and reduce the overall magnetic strength of the wire rod.

- Q: What are the different surface cleaning methods for steel wire rod?

- There are several surface cleaning methods that can be used for steel wire rods. These methods are designed to remove any impurities or contaminants on the surface of the wire, ensuring its cleanliness and enhancing its quality. Some of the different surface cleaning methods for steel wire rods include: 1. Mechanical cleaning: This method involves the use of mechanical abrasion to remove surface impurities. It can be done through processes such as wire brushing, sanding, or shot blasting. Mechanical cleaning is effective in removing rust, scale, or other loose particles from the surface of the wire rod. 2. Chemical cleaning: Chemical cleaning methods use various chemicals to dissolve or react with contaminants on the wire rod's surface. Acid pickling is a common chemical cleaning method used for steel wire rods, where the wire is immersed in an acid solution to remove oxide layers, scale, or other impurities. Alkaline cleaning is another option, which uses alkaline solutions to remove organic contaminants. 3. Electrochemical cleaning: This method involves the use of an electrical current to remove impurities from the wire rod's surface. Electrochemical cleaning processes, such as electrochemical pickling or electrocleaning, use an electrolyte solution and an electric current to dissolve or dislodge contaminants. This method is often used for stainless steel wire rods to maintain their corrosion resistance. 4. Ultrasonic cleaning: Ultrasonic cleaning utilizes high-frequency sound waves to create microscopic bubbles in a cleaning solution. These bubbles, known as cavitation, implode on the surface of the wire rod, effectively removing contaminants. Ultrasonic cleaning is particularly effective in removing oils, greases, or other organic substances from the wire rod's surface. 5. Steam cleaning: Steam cleaning involves the use of high-pressure steam to clean the surface of the wire rod. The steam's heat and pressure help to dislodge and remove contaminants. This method is often used for wire rods that are heavily contaminated with oils, greases, or other sticky substances. It is important to note that the choice of surface cleaning method for steel wire rods depends on factors such as the type and severity of contamination, the desired level of cleanliness, and the specific requirements of the wire's end application. Each cleaning method has its own advantages and limitations, and it is crucial to select the most appropriate method to ensure the highest quality and performance of the steel wire rod.

- Q: How are steel wire rods packaged and shipped?

- To ensure the safety and integrity of steel wire rods during transportation, a specific packaging and shipping process is followed. This process consists of several steps. Firstly, steel wire rods are typically bound together using steel straps or wires. This bundling process ensures that the rods stay aligned and tightly secured, preventing any potential movement or damage while in transit. Furthermore, it helps maintain the shape and structure of the rods. Once bundled, the steel wire rods are loaded onto pallets or wooden skids. These pallets provide a stable base and allow for easy handling with forklifts or cranes. The rods are carefully placed on the pallets, ensuring proper balance to evenly distribute the weight. After being loaded onto pallets, the steel wire rods are often wrapped with stretch film or other protective material. This wrapping not only secures the rods to the pallet but also shields them from moisture, dust, and other environmental factors during transportation. Additionally, to enhance protection, steel wire rods may be packaged in wooden crates or steel frames. These additional packaging options provide an extra layer of security, safeguarding the rods against potential damage during handling and transportation. Once properly packaged, the steel wire rods are ready for shipping. Depending on factors such as destination and volume, they can be transported via trucks, trains, ships, or airplanes. The choice of transportation method is determined by considerations such as distance, cost, and urgency. During shipping, it is crucial to handle the packaged steel wire rods with care. Appropriate equipment should be used for loading and unloading to minimize the risk of damage. Furthermore, the packages must be adequately secured within the transportation vehicle to prevent any movement or shifting during transit. In conclusion, the packaging and shipping of steel wire rods involve bundling, palletizing, wrapping with protective material, and potentially using additional packaging such as crates or frames. The packaged rods are then transported through various means, ensuring proper handling and security to maintain their quality and integrity.

- Q: What are the different types of steel wire rod surface cleaning equipment?

- In today's market, there is a wide range of steel wire rod surface cleaning equipment available. These options include the following: 1. Shot blasting machines: Shot blasting is a popular technique used to clean steel wire rod surfaces. It involves the high-speed projection of small steel balls or beads onto the surface, effectively eliminating dirt, rust, and scale. Shot blasting machines are available in different sizes and capacities, and can be either airless or air-powered. 2. Wire brushing machines: To clean steel wire rod surfaces, wire brushing machines utilize rotating brushes made of stiff bristles. These brushes effectively remove dirt, rust, and scale. They are available in various configurations, including hand-held tools and automated systems. 3. Ultrasonic cleaning machines: Ultrasonic cleaning is a non-abrasive method that employs high-frequency sound waves to eliminate contaminants from steel wire rod surfaces. The rods are immersed in a tank filled with a cleaning solution and then subjected to ultrasonic vibrations. This method is particularly effective in removing stubborn contaminants like oil and grease. 4. Chemical cleaning equipment: Chemical cleaning equipment utilizes cleaning solutions or acids to remove dirt, rust, and scale from steel wire rod surfaces. The rods are typically dipped or sprayed with the cleaning solution and then rinsed with water. The scale of the operation determines whether the chemical cleaning equipment is manual or automated. 5. Mechanical descaling machines: Mechanical descaling machines are specifically designed to eliminate scale from the surface of steel wire rods. These machines utilize rotating brushes, rollers, or abrasive belts to scrape off the scale. Mechanical descaling machines are often used in conjunction with other surface cleaning methods to achieve the desired level of cleanliness. Ultimately, the selection of steel wire rod surface cleaning equipment depends on factors such as the degree of contamination, desired cleanliness, and production capacity. Each type of equipment has its own advantages and limitations, making it crucial to choose the most suitable option based on specific cleaning requirements.

- Q: What are the common production processes for americium-coated steel wire rod?

- The common production processes for americium-coated steel wire rod typically involve surface preparation, application of the americium coating, and post-treatment steps. The surface preparation includes cleaning and degreasing the steel wire rod to ensure proper adhesion of the coating. The americium coating is then applied using techniques like electroplating or physical vapor deposition. Finally, post-treatment steps such as annealing or heat treatment may be performed to enhance the coating's durability and functionality.

- Q: What are the different types of steel wire rod surface defects?

- There are several types of steel wire rod surface defects, including scale, pits, scratches, rust, cracks, and uneven surfaces.

- Q: How is steel wire rod used in the manufacturing of wire forms for garage doors?

- The manufacturing process of wire forms for garage doors heavily relies on steel wire rod. This essential component acts as the primary material for producing sturdy and long-lasting wires used in the construction of garage doors. To begin with, the selection of steel wire rod is a meticulous process that considers specific qualities like strength, flexibility, and resistance to corrosion. These characteristics ensure that the wires created from the rod can endure the daily tension and stress experienced by garage doors. The manufacturing process commences with the introduction of the steel wire rod into a wire drawing machine. This machine progressively elongates the rod, decreasing its diameter while increasing its length. By repeating this process, the wire is shaped to the desired diameter and length suitable for wire forms. Once the wire has been drawn, it is then molded into various forms crucial for the proper functioning of the garage door. For example, it can be bent or coiled to form springs that provide the necessary counterbalance for the door's weight. These springs are vital to ensure the smooth operation and correct balance of the garage door. Moreover, the wire can also be shaped into cables or tracks that guide the movement of the garage door along its designated path. These cables and tracks guarantee a secure and seamless movement of the door, minimizing any potential damage or accidents. Additionally, steel wire rod is utilized in the creation of reinforcement bars, which add strength and stability to different components of the garage door. These reinforcement bars are strategically placed in areas prone to stress and strain, such as hinges and tracks, to prevent deformation or failure. In conclusion, steel wire rod plays an indispensable role in manufacturing wire forms for garage doors. Its strength, flexibility, and resistance to corrosion make it the ideal material for producing wires capable of meeting the demanding requirements of garage door operation.

Send your message to us

Carbon Steel Hot Rolled Wire Rod with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords