Stainless Steel Plate AISI 316 with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate:

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions, when the sulfuric acid concentration is less than 15% or greater than 85%, 316L stainless steel with a wide range of purposes.

Festures of stainless steel plate:

| Packaging Details: | standard packing to export 4 eye bands and 3 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges |

| Delivery Detail: | 15-25 days after received your deposit or to your quantity |

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | Kitchenware, decoration construction and building ornament |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. |

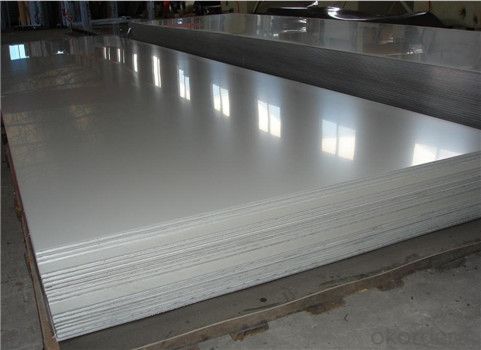

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the main regions for steel wire rod production?

- Asia, Europe, and North America are the primary regions where steel wire rod production takes place. In Asia, China, Japan, and India are the leading countries in steel wire rod production. China, in particular, holds the largest share of global production due to its extensive steel industry and strong domestic demand. Japan is also a significant player, known for its advanced technology and high-quality steel products. India has emerged as a major producer in recent years, driven by its expanding infrastructure and construction sectors. Europe, on the other hand, boasts prominent steel wire rod producers such as Germany, Italy, and France. Germany, with its long history of steel manufacturing, is renowned for its expertise in producing top-notch steel wire rod. Italy specializes in stainless steel wire rod production and is also a significant player in the industry. France benefits from its strategic location and serves as a hub for steel wire rod distribution throughout Europe. North America is another crucial region for steel wire rod production, with the United States and Canada playing key roles. The United States has a well-established steel industry and is known for its advanced production techniques. Canada, although not as large a producer as the United States, still makes a significant contribution to the North American market. Overall, these regions dominate global steel wire rod production and each has its own strengths and specialties. The demand for steel wire rod continues to grow, fueled by various industries such as automotive, construction, and manufacturing, ensuring a strong market for these regions.

- Q: What are the common production processes for francium-coated steel wire rod?

- The common production processes for francium-coated steel wire rod typically involve hot rolling the steel wire rod to the desired diameter, followed by cleaning and preparation of the surface. The wire rod is then coated with a layer of francium using various methods such as electroplating or vapor deposition. After the coating process, the wire rod undergoes further heat treatment and cooling to ensure proper adhesion and durability of the francium coating. Finally, the finished francium-coated steel wire rod is inspected and packaged for distribution.

- Q: How is steel wire rod used in the manufacturing of wire rope turnbuckles?

- Steel wire rod is used in the manufacturing of wire rope turnbuckles as the primary material for creating the wire ropes. The wire rod is first drawn and shaped into individual wires, which are then twisted and braided together to form strong and durable wire ropes. These wire ropes are then incorporated into the construction of turnbuckles, providing the necessary tensile strength and flexibility for adjusting and securing loads in various applications.

- Q: What are the different transportation methods for steel wire rod?

- Different transportation methods are available for steel wire rod, depending on the distance and logistics involved. Some common options include: 1. Trucking: Trucks are a versatile and popular choice for transporting steel wire rod. They can carry large quantities and reach various locations, including remote areas. Trucking is suitable for both domestic and international shipments, particularly for shorter distances. 2. Rail transport: Rail transport is efficient for long-distance transportation of steel wire rod. It has a higher capacity and can handle heavy loads. This method is commonly used to ship steel wire rod from manufacturing plants to distribution centers or ports, providing cost-effective and reliable transportation. 3. Ocean freight: International transportation of steel wire rod can be done through ocean freight. This involves loading the cargo onto cargo ships in containers or as bulk cargo. Ocean freight is suitable for long distances, especially for exporting or importing steel wire rod to different countries. 4. Air freight: Although costly, air freight is an option for fast delivery of steel wire rod. Airplanes can carry smaller quantities and are often used for urgent or time-sensitive shipments. This method is particularly beneficial for international trade or when transporting to remote areas with limited road or rail access. 5. Barge transport: Barge transport is effective for areas with accessible waterways. Barges are flat-bottomed boats designed for heavy cargo, including steel wire rod. This mode of transportation is commonly used for inland waterways like rivers and canals, offering cost-effective and environmentally friendly options. When selecting the appropriate transportation method for steel wire rod, it is important to consider factors such as cost, distance, delivery time, and logistics requirements. Each method has its advantages and limitations, and the choice depends on the specific needs and circumstances of the shipment.

- Q: What are the different types of steel wire rod surface finishes after wire drawing?

- There are several types of steel wire rod surface finishes that can be achieved after wire drawing. These include bright finish, black finish, galvanized finish, and coated finish. The bright finish is achieved by polishing the wire rod, resulting in a shiny and smooth surface. The black finish is obtained through a process called annealing, which involves heating the wire rod to a high temperature and then cooling it slowly, resulting in a darkened surface. The galvanized finish is achieved by applying a layer of zinc coating to the wire rod, providing protection against corrosion. Lastly, the coated finish involves applying a layer of specialized coating, such as PVC or nylon, to the wire rod for specific applications or enhanced properties.

- Q: Can steel wire rod be galvanized?

- Yes, steel wire rod can be galvanized.

- Q: What are the different surface lubricants used for steel wire rod?

- There are several different surface lubricants that are commonly used for steel wire rod. These lubricants are applied to the surface of the wire rod to reduce friction and improve the drawing process. One commonly used lubricant is a water-based emulsion. This type of lubricant contains a mixture of water and oil, along with additives to enhance its lubricating properties. Water-based emulsions are often used for drawing operations that require high-speed and high efficiency. Another type of lubricant used for steel wire rod is a dry lubricant. Dry lubricants are typically powder-based and are applied to the surface of the wire rod in dry form. These lubricants can provide excellent lubrication properties while minimizing the potential for contamination or mess. Some steel wire rod manufacturers also use oil-based lubricants. These lubricants are typically petroleum-based and can provide good lubrication properties for a wide range of drawing operations. However, oil-based lubricants may require additional cleaning steps to remove any residual oil from the wire rod surface. In addition to these commonly used lubricants, there are also specialty lubricants available for specific applications. For example, some wire rod manufacturers may use graphite-based lubricants for drawing operations that require high temperatures or extreme pressures. Overall, the choice of surface lubricant for steel wire rod will depend on factors such as the specific drawing operation, the desired level of lubrication, and any specific requirements or restrictions for the end product.

- Q: What are the common industry skills for steel wire rod distributors?

- Some common industry skills for steel wire rod distributors include knowledge of the steel industry, understanding of market trends and customer demands, strong communication and negotiation skills, ability to analyze data and make informed decisions, proficiency in supply chain management, and excellent customer service skills.

- Q: How is steel wire rod used in the production of wire mesh for automotive filters?

- Steel wire rod is used in the production of wire mesh for automotive filters by being drawn into thin wires, which are then woven together to create a durable and strong mesh structure. This wire mesh acts as a filter by trapping and preventing contaminants from entering the automotive system, ensuring clean air and fluid flow for optimal performance and engine protection.

- Q: How is steel wire rod used in the production of wire strands for electrical transmission lines?

- Steel wire rod is an essential component in the production of wire strands for electrical transmission lines. These wire strands are used to provide the necessary strength and conductivity for transmitting electricity over long distances. The process begins with the steel wire rod being drawn through various dies to reduce its diameter and increase its length. This drawing process helps to refine the steel and improve its mechanical properties, such as tensile strength and flexibility. Once the desired diameter is achieved, the steel wire rod is then twisted and formed into multiple individual wires, usually six or seven, which are then grouped together to form a wire strand. This twisting process helps to enhance the overall strength and durability of the wire strand. The wire strands are then coated with a protective layer, such as zinc or aluminum, through a process called galvanization. This coating not only provides corrosion resistance but also helps to improve the electrical conductivity of the wire strand. The wire strands are finally assembled into a larger conductor, along with other components such as steel or aluminum wires, to create the electrical transmission line. These transmission lines are responsible for carrying high voltage electricity from power plants to substations, where it is then distributed to homes, businesses, and other facilities. In summary, steel wire rod is a crucial raw material in the production of wire strands for electrical transmission lines. Through a series of processing steps, including drawing, twisting, and galvanization, the steel wire rod is transformed into wire strands that possess the necessary strength, conductivity, and durability required for transmitting electricity efficiently and reliably.

Send your message to us

Stainless Steel Plate AISI 316 with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords