Stainless Steel sheet 202 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321,410/420/430/444/443/409L, and 904L.

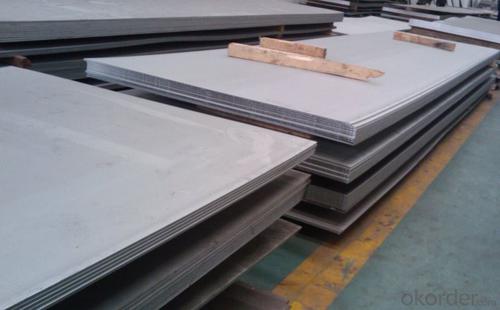

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

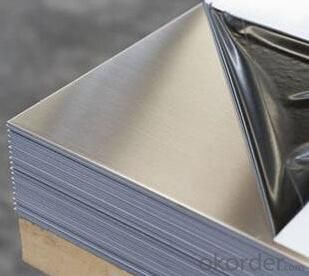

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

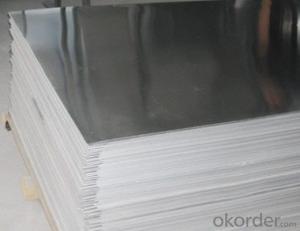

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What's the difference between 304 stainless steel and 301 stainless steel?

- 304 stainless steel is one kind of universal, which is widely used to produce good performance (corrosion resistance and formability) equipment and parts; 301 stainless steel showed obvious hardening during deformation, is used for various occasions with high intensity.

- Q: What are the standard sizes of stainless steel sheets?

- The standard sizes of stainless steel sheets can vary depending on the specific requirements and applications. However, common standard sizes for stainless steel sheets include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet. Other sizes may also be available based on customer needs and supplier capabilities.

- Q: Can stainless steel sheets be used for conveyor belts?

- Yes, stainless steel sheets can be used for conveyor belts. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various industrial applications, including conveyor belts. Stainless steel sheets can withstand high temperatures, heavy loads, and abrasive materials, making them ideal for conveying purposes. Additionally, stainless steel's smooth surface allows for easy movement of products and minimizes friction, resulting in efficient and reliable conveyor operations.

- Q: How do I determine the hardness of stainless steel sheets?

- To determine the hardness of stainless steel sheets, there are a few methods you can use. One common method is the Rockwell hardness test, which measures the depth of penetration of an indenter into the material. The Rockwell scale has different scales depending on the material, so you will need to use the appropriate scale for stainless steel. To perform the Rockwell hardness test, you will need a Rockwell hardness tester and a diamond or tungsten carbide indenter. Start by placing the stainless steel sheet on a flat, stable surface. Then, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. Once the load has been applied and released, the hardness value will be displayed on the Rockwell hardness tester's dial or digital display. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to note that the Rockwell hardness test provides a relative measurement of hardness and does not necessarily reflect the material's physical properties. Additionally, the hardness of stainless steel can vary depending on factors such as the alloy composition, heat treatment, and manufacturing process. Therefore, it is recommended to consult the material's specifications or conduct additional tests to obtain more accurate and comprehensive information about the stainless steel sheet's hardness.

- Q: Are stainless steel sheets available in different thicknesses?

- Stainless steel sheets of different thicknesses are readily available. They can be found in a range of thicknesses, from very thin to thick. For various applications, common thicknesses include 0.4mm, 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, and even thicker. The required thickness will depend on the intended use and the specific requirements of the project, whether they be structural or aesthetic. Different thicknesses of stainless steel sheets provide varying levels of strength, durability, and resistance to corrosion.

- Q: What are the different types of perforated finishes available for stainless steel sheets?

- Stainless steel sheets offer a range of perforated finishes, each with its own distinct appearance and functionality. The most widely used finish is the round hole, which features evenly spaced circular perforations, providing a sleek, contemporary look. For a more simplistic yet noticeable finish, the square hole is a popular choice. Like the round hole, it has evenly spaced perforations, but in a square shape. Another option is the slotted hole finish, which offers elongated holes that can be either straight or staggered. This finish is often chosen for its decorative appeal and ability to enhance ventilation. For a visually captivating pattern, the hexagonal hole finish is an excellent choice. With its six-sided holes, it creates a modern and eye-catching design, making it ideal for architectural applications. In addition to the standard hole shapes, stainless steel sheets can also be perforated with decorative patterns. These patterns can range from floral designs to abstract shapes, allowing for a personalized and unique finish. When selecting a perforated finish for stainless steel sheets, it is crucial to consider factors such as the desired appearance, functional requirements, and the specific application. By taking these factors into account, one can choose the perfect perforated finish to meet their needs.

- Q: Can stainless steel sheets be custom-cut?

- Yes, stainless steel sheets can be custom-cut to specific sizes and shapes according to the requirements of the project or application.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- Fretting corrosion can be a common issue with stainless steel sheets, but there are several steps you can take to prevent it: 1. Proper Handling: When handling stainless steel sheets, it is crucial to avoid any scratching or rubbing of the surface that could lead to fretting corrosion. Use gloves and avoid contact with other metals or rough surfaces. 2. Cleaning: Regularly clean the stainless steel sheets using mild detergents or specialized stainless steel cleaners. This helps remove any contaminants that can initiate corrosion and also prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Lubrication: Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion. This is especially important in applications where there is repeated movement or vibration. 4. Avoiding Metal-on-Metal Contact: Whenever possible, try to isolate stainless steel sheets from direct contact with other metals. This can be done by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular Inspection: Periodically inspect the stainless steel sheets for any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Protective Coatings: Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. Consult with a professional to determine the most suitable coating for your specific application. 7. Proper Storage: When not in use, store stainless steel sheets in a clean, dry environment to minimize exposure to moisture or corrosive substances. Ensure that the storage area is well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, you can significantly reduce the risk of fretting corrosion on stainless steel sheets and prolong their lifespan.

- Q: Can stainless steel sheets be used for electrical enclosures?

- Yes, stainless steel sheets can be used for electrical enclosures. Stainless steel has excellent corrosion resistance, good mechanical properties, and high durability, making it suitable for protecting electrical components in various environments. Additionally, stainless steel's conductivity and ability to dissipate heat make it a reliable choice for electrical enclosures.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, there are several measures that can be taken: 1. Regular cleaning and maintenance: Keeping the stainless steel sheets clean and free from any contaminants is crucial in preventing crevice corrosion. Regular cleaning with mild detergent and water, followed by thorough rinsing and drying, helps remove any potential corrosive agents. 2. Avoiding accumulation of debris or moisture: It is important to ensure that there are no crevices or gaps where debris or moisture can accumulate. Regular inspection and maintenance can help identify and rectify any such areas. Additionally, maintaining good drainage systems and avoiding water pooling can help prevent the accumulation of moisture, which can contribute to crevice corrosion. 3. Applying protective coatings: Applying a protective coating on the stainless steel sheets can provide an additional barrier against crevice corrosion. There are various types of coatings available, such as paints, epoxy coatings, or specialized corrosion-resistant coatings specifically designed for stainless steel. 4. Using appropriate gaskets and sealants: When fastening or joining stainless steel sheets, it is important to use compatible gaskets and sealants. These should be resistant to corrosion and provide a barrier against moisture and contaminants. Silicone-based sealants or gaskets made from PTFE (polytetrafluoroethylene) are commonly used for this purpose. 5. Preventing galvanic corrosion: Galvanic corrosion can occur when dissimilar metals come into contact with each other in the presence of an electrolyte, leading to corrosion of the less noble metal. To prevent this, it is important to avoid using dissimilar metals in close proximity to stainless steel sheets. If it is necessary to use dissimilar metals, insulating materials or coatings can be used to separate them. 6. Regular inspection and maintenance: Regularly inspecting the stainless steel sheets for any signs of corrosion and addressing them promptly is essential in preventing crevice corrosion. This includes checking for any signs of pitting, discoloration, or degradation of the protective coatings. Any identified issues should be addressed immediately to prevent further corrosion. By following these preventive measures, crevice corrosion on stainless steel sheets can be effectively minimized, ensuring their longevity and maintaining their aesthetic appeal.

Send your message to us

Stainless Steel sheet 202 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords