Stainless steel round bar Q234 for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

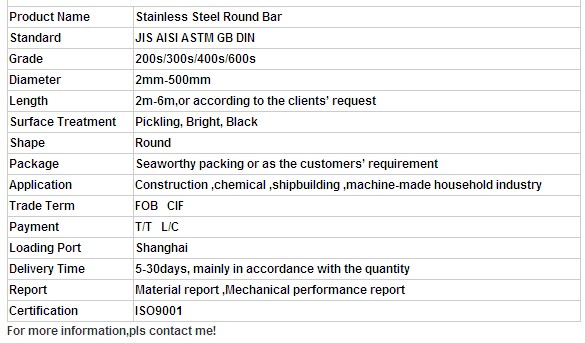

Product Description:

OKorder is offering Stainless steel round bar Q234 for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Stainless steel round bar Q234 for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Stainless steel round bar Q234 for construction are durable, strong, and resist corrosion.

Main Product Features:

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What is the difference between a rough turned and a hot rolled steel round bar?

- A rough turned steel round bar and a hot rolled steel round bar differ in their manufacturing processes and resulting properties. A rough turned steel round bar is produced by first heating a steel billet or ingot to a high temperature and then subjecting it to rough machining processes. The rough machining involves removing excess material from the surface of the bar to achieve a desired size and shape. This process results in a slightly smoother surface compared to the hot rolled bar, but it may still have some minor imperfections. Rough turned bars are often used in applications where a smoother surface finish is required, such as in machining operations. On the other hand, a hot rolled steel round bar is manufactured by heating a steel billet or ingot to extremely high temperatures and then passing it through a series of rolling mills. The hot rolling process involves reducing the thickness and increasing the length of the steel bar by compressing it between a set of rotating rolls. As a result, hot rolled bars have a rough, scaled surface with variations in diameter along their length. This textured surface provides excellent adherence for paint, coatings, or further processing. Hot rolled bars are commonly used in construction, manufacturing, and structural applications where mechanical properties such as strength and durability are important. In summary, the main difference between a rough turned and a hot rolled steel round bar lies in their manufacturing processes and surface finish. Rough turned bars undergo rough machining to achieve a smoother surface, while hot rolled bars are formed through high-temperature rolling, resulting in a rough, scaled surface. The choice between these two types of bars depends on the specific application and the desired properties, such as surface finish, strength, and adherence.

- Q: Are steel round bars suitable for welding applications?

- Yes, steel round bars are suitable for welding applications. Steel is a commonly used material in welding due to its high strength and durability. Round bars have a consistent shape and provide good stability and support during the welding process. They can be easily welded using various methods such as MIG, TIG, or stick welding, making them ideal for a wide range of welding applications in industries like construction, manufacturing, and automotive.

- Q: What is the difference between a bright and a black steel round bar?

- The main difference between a bright and a black steel round bar is the surface finish. A bright steel round bar has a smooth and shiny surface due to the additional processing steps it undergoes, such as pickling or cold drawing. On the other hand, a black steel round bar has a rough and dark surface due to the absence of these additional processing steps. Additionally, the black steel round bar may also have a coating of oil or rust inhibitor to protect it from corrosion.

- Q: Excuse me and steel disc round what is the difference?

- Round steel is a solid strip of steel whose cross section is round. Its specifications are expressed in diameter, in units of millimeters (mm), such as "50mm", which means a diameter of 50 millimeters of round steel. Round bar is divided into three parts: hot rolling, forging and cold drawing. Standard Specification for hot rolled round steel is 5.5-250 mm. Where: 5.5-25 mm small round steel mostly straight bundles of supply, used for steel, bolts and various mechanical parts; greater than 25 mm round steel, seamless steel pipe is mainly used for the manufacture of mechanical parts of the tube, etc..

- Q: How do you calculate the strength of a steel round bar?

- To calculate the strength of a steel round bar, several factors need to be considered. The primary factor is the material's yield strength, which represents the stress level at which the steel begins to deform permanently. This value is typically provided by the manufacturer or can be found in engineering handbooks. Next, the cross-sectional area of the round bar needs to be determined. This can be done by measuring the diameter of the bar and using it to calculate the area using the formula A = πr^2, where A is the cross-sectional area and r is the radius. Once the cross-sectional area is known, the ultimate tensile strength (UTS) can be calculated using the formula UTS = Yield Strength / Safety Factor. The safety factor is a numerical value that accounts for uncertainties and potential variations in the material's strength. It is typically specified by the design requirements or industry standards. Finally, the maximum load that the steel round bar can withstand before failure can be determined by multiplying the ultimate tensile strength by the cross-sectional area. This value represents the strength of the round bar and can be used to assess its suitability for a particular application. It is important to note that other factors such as the bar's length, shape, and any additional treatments or modifications can also affect its strength. Therefore, consulting with a structural engineer or referring to relevant design codes and standards is recommended to ensure accurate calculations and safe application of steel round bars.

- Q: Can steel round bars be used for making security grilles?

- Yes, steel round bars can be used for making security grilles. The strength and durability of steel make it an excellent choice for security applications, providing protection and ensuring the safety of premises.

- Q: Can steel round bars be used for making sway bars?

- Yes, steel round bars can be used for making sway bars.

- Q: What is the difference between carbon steel and stainless steel round bars?

- The main difference between carbon steel and stainless steel round bars lies in their composition. Carbon steel round bars are primarily made of iron and carbon, while stainless steel round bars contain iron, carbon, and at least 10.5% chromium. This chromium content in stainless steel gives it its characteristic resistance to corrosion and staining, making it suitable for various applications in industries such as construction, automotive, and food processing. On the other hand, carbon steel round bars are generally stronger and more durable but lack the corrosion resistance of stainless steel.

- Q: Are steel round bars available in different shapes?

- No, steel round bars are typically only available in a cylindrical or circular shape. The term "round bar" refers specifically to the shape of the steel, which is typically a solid cylindrical piece. However, there are other types of steel bars available in different shapes, such as square bars, flat bars, or hexagonal bars, which offer different properties and uses.

- Q: How do steel round bars perform under vibration or resonance?

- Steel round bars generally perform well under vibration or resonance due to their high strength and stiffness. The inherent properties of steel, such as its high modulus of elasticity and low damping characteristics, make it an ideal material for applications that involve vibration or resonance. When subjected to vibration or resonance, steel round bars tend to exhibit minimal deformation or deflection. This is because steel has a high natural frequency, which allows it to resist the excitation caused by external forces or vibrations. The high stiffness of steel also helps in maintaining its shape and integrity under these conditions. Furthermore, steel round bars have good fatigue resistance, which means they can withstand repeated loading and unloading cycles without significant degradation in performance. This is especially important in applications where the material is subjected to cyclic loading or vibrations over an extended period. However, it is worth noting that the performance of steel round bars under vibration or resonance can be influenced by factors such as the design of the structure, the applied loads, and the frequency and amplitude of the vibrations. In some cases, additional measures, such as damping materials or isolation systems, may need to be implemented to mitigate the effects of vibration or resonance on steel round bars. Overall, steel round bars are known for their excellent performance under vibration or resonance, making them a popular choice in various industries, including construction, automotive, and aerospace. Their high strength, stiffness, and fatigue resistance make them reliable and durable materials for applications that involve dynamic loads or vibrations.

Send your message to us

Stainless steel round bar Q234 for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords