SMC Sheet - Wool Board Insulation with Excellent Fire Resistance and Thermal Properties

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Rock Wool:

Rock Wool Continuous conveyors transport the mat to the COLD END of

the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete rock wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

2.Main features of Rock Wool :

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

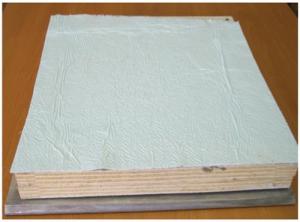

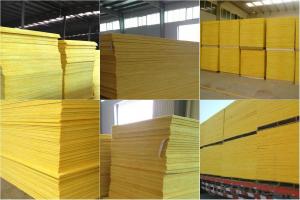

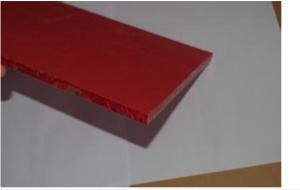

3. Rock Wool Images:

4. Rock Wool Technical Parameters:

Performance: high / low temperature resistance, oil resistance, fuel resistance,

Weather resistance, tolerance, etc.

There are a lot of practical use - rockwool products; the following are some of the major areas:

In - rockwool thermoacoustic field used for various types of buildings and the use of thermal insulation, such as housing, Department store,

Office buildings, stadiums, airports, etc..

In the insulation of industrial plants and machinery systems, etc.:

Cool store.

Refinery.

Chemical and petrochemical plant.

Central air-conditioning

Hot water and chilled water system.

For industrial purposes, - rockwool used in many industries:

Industrial furnaces and ovens.

It is widely used in heat preservation and industrial plants, prefabricated houses, portable cabins, warehouses, public facilities, exhibition centers, large shopping centers, the sound absorption, as well as a variety of indoor amusement parks, sports venues, etc..

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rock wool is one of the large

scale professional investment casting production bases in China.Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Where are the differences between the products made of stone and resin?

- At present, the latest home improvement, tooling, polymer composite suspended ceiling is the use of high-grade ester SMC sheet production, there is no pollution problems, you can use a lot, installation is relatively simple and fast.

- Q: What composite material is used for composite manhole covers?

- The composite well covers adopts unsaturated polyester resin as matrix and fiber reinforced thermosetting composite material, also called group molding plastics (DMC). It is made of pressing molding technology, and it is a new type of environmental protection type electric power cover plate.

- Q: Is the gas released from the heating of the SMC sheet poisonous?

- SMC sheet is made of unsaturated polyester resin, glass fiber and aluminium hydroxide powder by certain process

- Q: Is the quality of the resin wall the same?

- From the installation form, it is divided into the gusset and the panel, the gusset plate is installed with the keel, and the panel is pasted on the wall with glue.

- Q: Which is good for SMC composites and honeycomb composites?

- 3D printing can now print cellular structures directly.

- Q: Does floor heating emit toxic gas?

- In the ceramic tile surface drops the right amount of water, after a period of time, looks at the ceramic tile bottom surface whether has the seepage phenomenon, if does not have, is the high grade ceramic tile, if has, is inferior ceramic tile

- Q: Who knows what is the process flow of FRP splicing water tank?

- Description of production process of glass fiber reinforced plastic water tank:Raw material purchasing: resin paste, glass fiber, laminating, coiling, thickening, cutting, weighing, molding, dressing, drilling, assembling.The prepared raw material is prepared according to a prescribed proportion, and then the paste is stirred into a resin paste; the resin paste and the glass fiber yarn are impregnated with SMC sheets to form a SMC sheet;

- Q: Why outdoor SMC table tennis table longer service life?

- SMC composite and its SMC molded products have excellent electrical insulation properties, mechanical properties, thermal stability and chemical resistance. Therefore, SMC products have a wide range of applications.

- Q: In recent years, what new materials have come into use in the automotive interior, or in the future?

- LFT is a kind of advanced fiber reinforced lightweight materials in the field, with design, low density, high specific strength, high specific modulus and strong impact resistance and other characteristics, it appears to Aluminum Alloy, fiber reinforced thermoset composites poses huge challenges, and gradually become the mainstream material production of auto parts.LFT Long-Fiber Reinforce is English Thermoplastic, Chinese for long fiber reinforced thermoplastic plastics, used to call the long fiber reinforced thermoplastic composites, it is a kind of advanced fiber reinforced lightweight polymer material field.

- Q: SMC sheet pressing out the product is not bright, what is the reason?

- Different grades of tree ester use different raw materials, new glycol, propylene glycol content of higher tree ester, made out of sheet pressure product brightness is better, but the higher the cost.

Send your message to us

SMC Sheet - Wool Board Insulation with Excellent Fire Resistance and Thermal Properties

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords