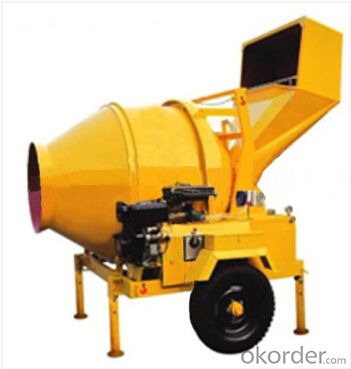

Small Volume Drum Concrete Mixer with Large Output

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: JZ350 Small Volume Drum Concrete Mixer for Sale

1. Specification

JZ Series conical inverted material mixer is the international advanced level of mixer, mixer drum can mix forward to mixing and reverse to discharge material, can mix dry hard, plastic, cartilage aggregate concrete, cement mortar, stabilized soil and other granular or powdered mixtures.

Model | JZ-350 | JZ350-R | JZ-200 | JZC-200 | Unit |

Feed capacity | 350 | 350 | 200 | 200 | L |

Discharge capacity | 560 | 560 | 320 | 320 | L |

Productivity | 10-14 | 10-14 | 6-8 | 6-8 | m3/h |

Mixing speed | 14 | 14 | 17 | 17 | r/min |

Maximum aggregate size | 60 | 60 | 60 | 60 | mm |

Water supply precision | ≤2 | ≤2 | ≤2 | ≤2 | % |

Mixing motor power | 5.5 | 15(diesel engine) | 3 | 3 | kw |

Lifting motor power | 5.5 | — | — | — | kw |

Water pump power | 0.55 | — | 0.75 | 0.75 | kw |

Dimensions (L × W × H) | 3850×2200×2800 | 3850×2200×2800 | 2250×1850×2750 | 2250×1850×2750 | mm |

Total Weight | 2200 | 2500 | 1300 | 1300 | kg |

2. Application

JZ Series conical inverted material mixer is the international advanced level of mixer, mixer drum can mix forward to mixing and reverse to discharge material, can mix dry hard, plastic, cartilage aggregate concrete, cement mortar, stabilized soil and other granular or powdered mixtures. They're the ideal equipment applicable to medium-sized buildings, roads, airports, ports, bridges, water, minerals and other projects.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce JZ350 Small Volume Drum Concrete Mixer for Sale according to customers request?

A4: Yes, we can produce JZ350 Small Volume Drum Concrete Mixer for Sale according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary faclities &skilled personnel at site for training.

Images:

- Q: What kind of machinery does the concrete wet spray machine belong to?

- It is mainly used in the fields of defense construction, transportation construction, energy industry construction and production, mining and other raw materials industrial construction and production, agriculture and forestry water conservancy construction, industrial and civil construction, urban construction, environmental protection and other fields.

- Q: Does the concrete wet spray machine need to be equipped with an air compressor?

- The domestic Xuguang Group New Construction Group, China Railway Construction Jiale, etc., imported wet jet cars are now supporting the Italian Matai vane air compressor, unique shape, machine integration control, compression efficiency is higher, and

- Q: What should you pay attention to when spraying concrete with a wet spray machine for tunnel works?

- Our site is the use of five new tunnel wet spray machine, a wide range of construction, easy to suck

- Q: Are there any differences between concrete dry and wet spray?

- Dry spray use of the mechanical structure is relatively simple, mechanical cleaning and troubleshooting easy.

- Q: What is the use of concrete wet spray machine

- 2, pump wet spray machine operating efficiency can reach 10m3 / h, greatly improving the construction efficiency.

- Q: What is concrete concrete and net spray concrete?

- The concrete is for reinforced concrete, prestressed concrete and so on.Net spray concrete is arranged on the surface of the steel mesh shotcrete.

- Q: What is the difference between concrete wet spray machine and dry spray machine?

- Wet spraying machine is a vegetation greening machinery and equipment, mainly used for highway (railway) slope greening, slope protection, mountain governance, mine green, desertification, landfill and other projects.

- Q: What is the difference between pouring concrete and shotcrete?

- 2, when the site of the day and night the average temperature of 3d below 5C or the minimum temperature below -3C, the winter construction should be handled, the concrete into the mold temperature should not be less than 5C.

- Q: What is the difference between artificial wet spray concrete and mechanical wet spray concrete?

- The efficiency of artificial injection is low, less than the robot spray fast; artificial spray angle is not the best, especially in the pouring arch, the nozzle is always tilted, the machine can be completely vertical, to achieve better spray;

- Q: What is the working principle of concrete wet spray machine?

- In the second beach, Xiaolangdi and other large water conservancy projects used, such as Switzerland MEYNADIER company's Robojet041 type concrete jet

Send your message to us

Small Volume Drum Concrete Mixer with Large Output

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords