Slab copper mould plate/continuous casting copper mould plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Description

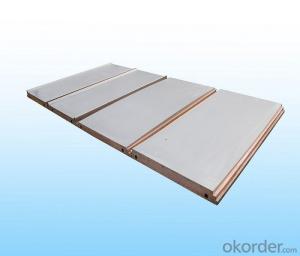

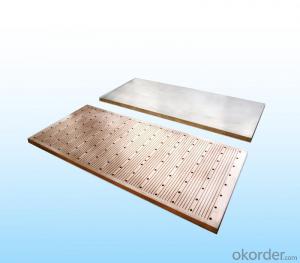

We are supplying High Slab copper mould plate with Size range Length 350-3800 Width 700-1000mm ,Thickness 30-75mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.which are the world's most Renowned and Reputed;

We supply Copper Moulds of Highest Quality, ensuring Maximum Life, excellent Heat Resistivity and smoothest Casting Operational efficiency.

CNBM, is the leading professional designer and manufacturer for copper mould tubes & plates as well as the complete sets of equipments & spare parts used for hundreds of domestic and abroad steel plants. The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market. We commit to supply products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service, and we can also give technical guidance to help our customers to reduce the cost and increase the productivity. We have got high reputation from various customers all over the world.

2.Main Features

Our design and manufature capacity: with slot single taper, double taper, triple taper, quadruplicate taper, parabolic taper and various of continous taper high effiency copper mould tube.

We are supplying High Slab copper mould plate with Size range Length 350-3800 Width 700-1000mm ,Thickness 30-75mm, Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

Steady and high quality,

We can design as per the customer’s specific requirements.

With lots of export expriences all around the world,

Fast shipment; 30-40days for production;

Packing : Strong, export worthy wooden cases.

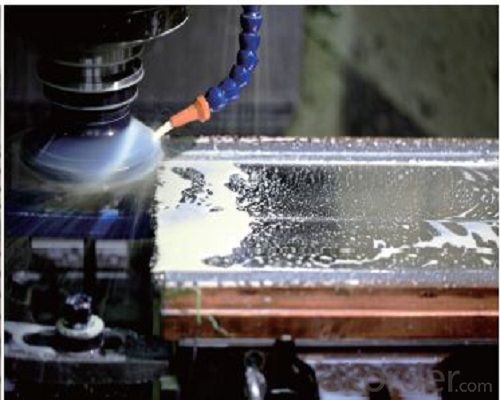

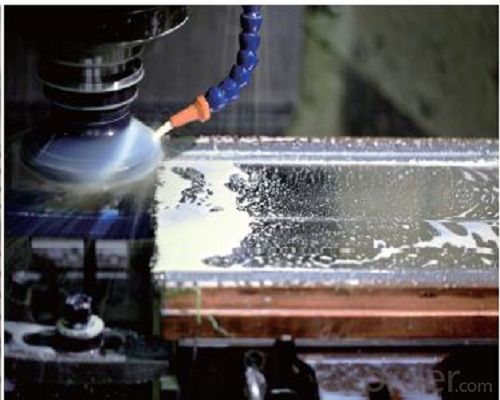

3. Images

4.Specification

Slab

Length 350-3800mm

Width 700-1000 mm

Thickness 30-75mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

* We can design as per the customer’s specific requirements.

- Q: When measuring the heat dissipation rate of copper plate, why should the sample be covered on it?

- In this experiment, the area involved in the heat dissipation is only the lower surface and the side. The upper surface is the part responsible for heat conduction, and a part of the heat is absorbed by the object to be measured, and this part of the heat is neglected.

- Q: Well, I need some help on finding info on slugs for a report. I need as many people to help as possible. I‘m doing some of my own work looking things up, but the more help the better. I‘m trying to persuade people to like slugs, show that they aren‘t too bad. Some interesting facts would be cool too. Thanks in advance. ^_^

- check this stuff out! i found it useful and u might too!! good luck with the report!

- Q: I have a 1984 El Camino that is missing the negative battery cable. I bought a replacement, and for the life of me I cant figure out where the other end attaches. any ideas?

- It is grounded to the frame. There should be a bolt hole near the battery mount.

- Q: I need to make a solar cell for a science project, and the instructions as well as other outside sources (namely, the Internet) all say I need an electric stove to heat the copper sheeting. However, I can‘t find a suitable electric burner because of time and shipping reasons and whatnot. What I actually need to know is whether I can use a gas stove instead of an electric stove and if not, why? Thanks!

- fix a flat will make your tire / wheel un balanced take it to the repair shop and have them put a patch on it

- Q: Laser and inkjet coated paper coated paper what is different

- But the average color laser can enter 250 grams of copper plate is tired, some machines are not able to enter. One word can change the feeder can enter. The Lexmark C910 color laser can print 300 grams of copper, but this machine is expensive. They usually buy 2 hands

- Q: I have copperish colored curtains and copper satin sheets with a brown comforter and bed frame, I don‘t know what colors to paint or to have with a table in the bedroom. Please serious answers only, thank you!

- use the high temperature blue gasket paper if you can find it ,it holds up well under all conditions,i got an older 6 horse power and that's what i use to make them for it,good luck.

- Q: My Sound Level Meter was fallen from the tripod and falling apart. The technican who is in charge of the repairing said we need to replace the battery and signal PCB.What is Signal PCB? I hope it is not Polychlorinated Biphenyls (PCBs).

- A printed circuit board, or PCB, is used to mechanically support and electrically connect electronic components using conductive pathways, or traces, etched from copper sheets laminated onto a non-conductive substrate. Alternative names are printed wiring board (PWB),and etched wiring board. A PCB populated with electronic components is a printed circuit assembly (PCA), also known as a printed circuit board assembly (PCBA). PCBs are rugged, inexpensive, and can be highly reliable. They require much more layout effort and higher initial cost than either wire-wrapped or point-to-point constructed circuits, but are much cheaper, faster, and consistent in high volume production. Much of the electronics industry's PCB design, assembly, and quality control needs are set by standards that are published by the IPC organization.

- Q: Wood GlassCopperNylonNickelPolystyreneCardboardSteel Perspex- I dun know what the hell it isHow many are there for conductor of heat?Mine answer: Three

- among these, copper, nickel and stell are conductors, but wood and glass are pure insulators,

- Q: What grams of coated paper?

- Before 40s, when the lithographic printing quality is low, such as senior art painting copy of classical paintings, mainly used this paper over the net in color art photography (letterpress) printed on coated paper, name it has been down. There are 100, 120, 150 quantitative and 180, 200 square meters, 250 grams Zhang Ping, packaging specifications for 787 x 1092 (mm), 880 x 1230 (mm). Coated paper is composed of a base paper by coating process, base paper is chemical wood pulp or mixed with 100% part of bleaching straw is made, the coating is composed of barium sulfate, kaolin, titanium dioxide and other white pigments casein, gelatin and adhesive composition, also added beeswax, glycerol and other accessories, used for coating paper, drying and super calendering and coating of coated paper. Single and double sided. The surface of white paper, smooth out. It has high smoothness and whiteness. It is suitable for printing color picture album, exquisite picture, advertisement trademark, color illustration and other high-grade printed matter. The domestic manufacturers of coated paper mainly include Shanghai gorgeous copperplate paper mill and so on

Send your message to us

Slab copper mould plate/continuous casting copper mould plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords