SK-220 Vertical Form Fill Seal Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wespecializein the production of packaging machinery soonkepillow packing machine, candy packaging machine, biscuit packaging machine, moon cake packaging machines, packaging machines preserves, candied fruits packaging machines, masks packaging machines, food packaging machine, packing machine, vertical packing machine, powder packing machine, liquid automatic packaging machine, tablet packing machine, automatic packaging machines, electronic weighing packaging machines, multi-functional packaging machine, puffed food packaging machines, snack food packaging machines, frozen food packaging machine, fried food packaging machines, milk powder packaging machine, soybean milk powder packaging machine, coffee powder packaging machine, packaging machine starch, flour packing machine, bulk packaging machines, strip packing machine, biscuit packaging machines, packaging machines crispy rice, peanut packaging machines, packaging machines seeds, beans packaging machine , potato chips packing machine, shrimp packaging machines, packaging machines banana slices, apple slices packaging machine, tea packing machine, jelly packing machine, packaging machine dumplings, dumpling packing machine, washing powder packaging machine, mung bean powder packing machines, metal parts packaging machine, plastic accessories packaging machine, nuts packing machine, salt packing machine, vegetable packing machine, ketchup packing machine, rice packing machine, beans packing machine, seed packaging machine, roasted packaging machines, feed packaging machine, tea packing machine, liquid packaging machines, semiautomatic packaging machines, packaging machines provincial labor, the provincial labor packaging machines, spices packing machine, water packing machine, popcorn packaging machines, packaging machines shower gel, shampoo packaging machines, cream packaging machines, juice packing machine, water packaging machines, animal kits installed, plum packaging machines, packaging machines soybeans, and small machines, small particle packing machine, powder material packing machine, rice packing machine, fruit packing machine, pharmaceutical packaging machines, etc. At present, the company's products has developed more than 20 series, widely used in food, chemical, pharmaceutical, hardware, daily necessities and other industries, in various fields to achieve the automatic measuring, feeding, filling, bag making, date printing, transportation, and all work is to improve the efficiency of preferred equipment; Meanwhile, pine may also manufacturers for many different industries, tailored some non-standard machine and get a lot of customers! Professional casting brand, brand achievements in the future.

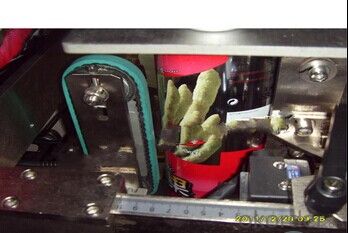

SK-220 vertical form fill seal machinery

Feature:

1. Featured with compact structure, stable, simple operation, convenient on repairing.

2. Adopts PLC with touch control screen,human machine interface,easy to learn and operation.

3. Servo film transporting system for accurate positioning, the bag is looking nice.

4. It can finish automatically all processes, from measuring, filling, bag forming , date printing and finished goods conveyance with different devices.

Applications:

Suitable for packing different kinds of products with different metering devices.

1. Electronic Weighing System

2. Volumetric Cup Metering Device

3. Semi-automatic Feeding Device

4. Auger Filler

5. Liquid Filling and Weighing Device

Optional Function:

1. Air flushing system

2. Nitrogen gas flushing

3. Hole punch device

4. Gusset device

5. Tear notch device

6. Linking bag device

7. Flip device

8. PE bag device

Model | SK-220 |

Air Consumption | 0.65Mpa,3M3/min,6kg/cm2 |

Packing Film Width | 180-420mm |

Bag Length | 80-300mm |

Bag Width | 80-200mm |

Packing Film Roll Diameter | Max.360mm |

Packing Speed | 5-70bags/min |

Packing Film Thickness | 0.04-0.08mm |

Packing Film Material | OPP/CPP,OPP/PE,BOPP/VMPET/PE etc. |

Power Supply | 220V,50/60Hz,2.4Kw |

Machine Size | (L)1100x(W)925x(H)1600mm |

Machine Net Weight | 400kg |

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width & bag length

3. Bag shape

4. Packing film material

5. Machine frame

- Q: Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: What are the main functions of packaging machinery and equipment?

- Sealing and other major operations, and related processes before and after,

- Q: What is the name of the paper used in packing machine parts and yellow?

- Also, according to the use of composite PE or textile cloth, in order to improve the physical strength and tightness.Hope to help you.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: What are the structures of the packaging machinery?

- Is far from a professional engaged in "packaging machinery" research and development, production, sales as one of the multinational enterprise groups. It is the largest manufacturer of packaging machinery in china. Located in the Chinese science and Education City - Hefei, the geographical position is superior, the traffic condition is convenient, and the sale network extends the whole country. Is far from, with a group of the world's top machinery manufacturing R & D team, specializing in all walks of life packaging enterprises, for the efficient production of enterprises to provide power. It is a large enterprise that put forward the concept of packaging automation earlier in china. Brand with strong economic strength, first-class R & D level, advanced business philosophy and good brand service, more and more people all over the world are respected and trusted. The entire manufacturing process in full accordance with the highest standards of global manufacturing; at the same time according to the quality standard of global market development process, operating procedures and quality control system of production, all is "far Machinery" have reached world-class standards. "Far distance machinery" combines the characteristics of all kinds of products in China, such as packaging machinery, food packaging machines, two times packaging machines, powder packaging machines, particle packaging machines, liquid packaging machines, weighing machines, and so on. It is well received by Chinese enterprises!

- Q: What's the fastest packing machine?

- Because the packaging machine type is more complicated, according to the state, liquid, bulk, powder, granular packing machine; according to the function of packaging, packaging, packaging machine in outsourcing; according to the packaging industry, food, daily chemical industry, metal parts, textiles and other packaging machine; according to the packing station. A single station and multi station packing machine; divided by automation, automatic packing machine, also has semi-automatic and so on. According to the form of sealing, it can be divided into back sealing type, three sides sealing, four sides sealing, triangle and so on. According to the product form, it can be divided into pillow type packaging machine, vertical packaging machine, vacuum packaging machine, sealing machine and so on

- Q: What is a packaging machine?

- Well, before and after the associated processes, such as cleaning, stacking and disassembly. In addition, the package also includes the measurement or in the processes of stamp packages. Mechanical packaging products can improve productivity, reduce labor intensity

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Molding: mainly used for thermosetting resins. There is a special molding machine. Molding pressure is much greater than the above. The mold structure is also more complex.

Send your message to us

SK-220 Vertical Form Fill Seal Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords