Sinter NdFeB Magnet with high quality and low price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rare earth Neodymium magnets (NdFeB) have been available for industrial application since 1984. Neo magnets have extremely high magnetic energy and therefore are used in applications which require high powered magnets, as well as applications where size and weight reduction are of interest or need to be considered. These qualities have made NdFeb magnets preferable over the commonly used larger and less powerful Ferrite magnets.

The main raw materials NdFeB permanent magnets are rare earth metal-Neodymium (Nd) 32%,metal element Iron (Fe) 64% and nonmetal element Boron(B) 1% , and some small amount added Dysprosium (Dy), Terbium(Tb), Cobalt (Co), Niobium(Nb),Gallium (Ga),Aluminum (Al),Copper (Cu) and other elements. Ternary system neodymium permanent materials are of Nd2Fe14B compound as a matrix, its compositions should be similar with the molecular formula of compound Nd2Fe14B, but, when it is proportioning according to the composition of Nd2Fe14B compound, the magnet performances are very low, and even without magnetic, just on the actual magnets, when the content of neodymium and boron are more than on Nd2Fe14B compound, we can get the better permanent magnet performances.

Neodymium magnets can be divided into three main groups:

1.Regular Neodymium

2.High corrosion resistant Neodymium

3.Bonded Neodymium (Isotropic): Manufactured by the injection of plastic material and Neodymium into a mold. This production method yields a very precise magnet which does not require further grinding and does not suffer substantial current loss.

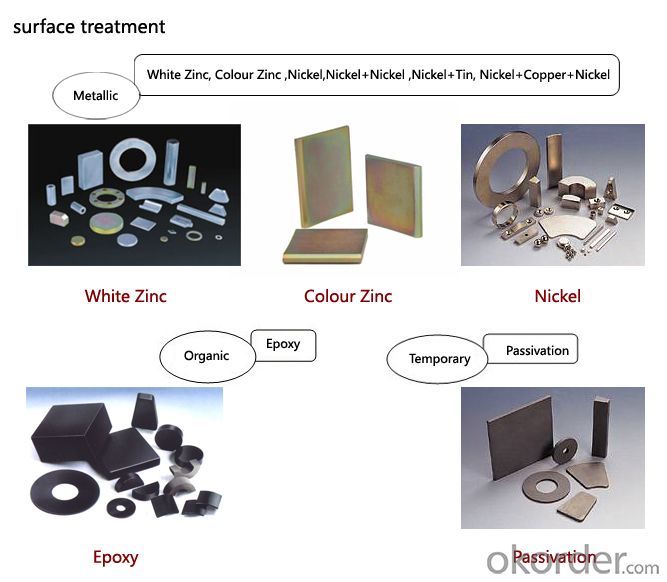

Neo magnets are known for their high temperature resistance, making them durable and functional in temperatures exceeding 200°C. This quality makes them ideal for heavy industry applications. Sintered Neodymium, however, is sensitive to oxidization and can develop corrosion, so magnets are usually coated with Nickel+Copper+Nickel,Nickel+Sn, Zn(galvanization), Epoxy and Passivation for their protection.

Characteristics of Surface Treatment

Coating Performance

| Zn | Colour Zn Cr3+ | NiSn | NiCuNi | Epoxy | Passivation |

Colour | White | Multicolor | Silver | Silver | Black | Silver |

Thickness(μm) | 6-15 | 6-15 | 10-30 | 10-30 | 10-30 | 1-5 |

Pressure Cooker Test (120℃,2atm,100%RH) | >8hr | >8hr | >24hr | >24hr | >24hr | |

Salt Spray Test (35℃,5%NaCl,1.2atm) | >24hr | >72hr | >48hr | >48hr | >96hr |

- Q: What metal will a magnetic sheet stick to best?

- copper and aluminum won't work. Some types stainless steel are magnetic, some are not. Only certain materials are magnetic. Iron, most steels, cobalt and nickel are the main ones. .

- Q: The magnetic permeability needs to be at least 12,000.

- I know what ur talking about and i cant think of the name of it !!

- Q: I bet you answer this question!

- Very simply, all the atoms that make up a magnetic material have a very slight magnetic field. When this is a magnet - which can be caused, for example, using another magnet, like when a magnet is used on a nail - all these atoms line up and their magnetic fields combine, causing an effect that can be observed and used. Any action that causes these atoms to lose their line will reduce the magnet's strength - dropping/hitting a magnet and passing a powerful electric current through it are two things that will do this, eventually removing any noticeable magnetism. Hope that helps!

- Q: SmCo and ferrite in magnetic energy on what is the difference? For brushless motor as specific as possible which good?!

- Ferrite can not be done, it is applied in high frequency, such as switching power supply

- Q: I sorta get that it redirects something, but what does it redirect and can you control where it redirects it to?

- As you suggest, the materials that can provide magnetic shielding work by redirecting the magnetic field. Magnetic materials do this by supporting the formation of a magnetic field and providing a preferred pathway for it to follow. These materials support the formation of magnetic fields by aligning their own magnetism with the field's (an alignment of their magnetic 'domains'). Where this happens the magnetic field follows the magnetic material instead of going through the air so the field is diverted rather than blocked. The strongest magnetic materials contain a high proportion of iron. Iron itself increases the strength of a magnetic field by about 700 times compared to air - ensuring magnetic field lines are diverted to follow a path through iron rather than through air.

- Q: what I thought was a stone skull is actually a magnetite skull. I was in my room when I heard a click, I looked on my night stand one of my buzzing magnets stuck to it but it has little magnetic force so I want to give it more force but how? I already tried rubbing it in a magnet and that has some effect but not enough.

- no car tires are not meant to be rolled onto the side like a m/c tire is

- Q: How is magnetism produced by a magnet?

- It can be thought of as the object, the magnet is a tiny part of the internal circuit for some reason (such as iron long nonmagnetic in constant magnetic field) have been arranged, the intensity of the magnetic field in one direction than other directions, so exhibit magnetic.

- Q: what are your thoughts on using powerful magnetic fields to compress matter, just curious. Like what potential might it really have, and how can it be used and improved. I have my own ideas, but I‘d love to hear others all in the name of curiosity anyway

- I might be wrong, but magnets only pull/ attract ferrous metals. Although, you can place something between two powerful magnets and the attractive forces will compress that material somewhat. We already have hydraulic machines for bailing cars and refrigerators and cardboard. I see no potential, sorry. Hang in there, maybe one of the really smart people on Answers will give you a better answer. Wingman

- Q: How many temperature magnets will degaussing?

- For all magnetic materials, they are not magnetic at any temperature. Generally, a magnetic material has a critical temperature Tc, at which the arrangement of atomic magnetic moments is disordered due to the intense thermal motion of atoms at high temperatures. Below this temperature, the magnetic moment of the atom is arranged in order, producing spontaneous magnetization, and the object becomes ferromagnetic.

- Q: What kind of magnetic material is manganese, paramagnetic or antiferromagnetic?

- Will not produce a magnetic field. This substance is not common, most of the anti ferromagnetic material exists only in low temperature condition. If the temperature exceeds the Neel temperature, usually into paramagnetic properties. For example, chromium, manganese, light lanthanides and so on, are anti ferromagnetic.

Send your message to us

Sinter NdFeB Magnet with high quality and low price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches