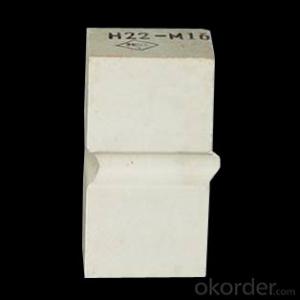

Silica Brick for Hot-Blast Stoves S-95B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX silica brick is a kind of acid refractory product which is mainly made of tridymite and cristobalite, and a small amount of quartz and vitreous. CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

Coke oven

Hot blast stoves

Glass furnace

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Technical Data

ITEM | For Hot-Blast Stoves | For Glass Furnace | ||||||

S-94 | S-95 | S-95B | G-94 | G-95A | G-95B | G-96A | G-96B | |

SiO2, % | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 94 | ≥ 95 | ≥ 95 | ≥ 96 | ≥ 96 |

Fe2O3, % | ≤ 1.5 | ≤ 0.5 | ≤ 1 | ≤ 1.5 | ≤ 1.2 | ≤ 1.2 | ≤ 0.8 | ≤ 1 |

Residual Quartz, % | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ||||

Apparent Porosity | ≤ 23 | ≤ 23(24) | ≤ 21(23) | ≤ 24 | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) | ≤ 22(24) |

True Density, g/cm 3 | ≤ 2.35 | ≤ 2.34 | ≤ 2.33 | ≤ 2.35 | ≤ 2.35 | ≤ 2.34 | ≤ 2.34 | |

Cold Crushing Strength, Mpa | ≥ 29.4 | ≥ 30(27) | ≥ 30(20) | ≥ 30 | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) | ≥ 30(35) |

Refractoriness Under Load, º C | ≥ 1650 | ≥ 1600 | ≥ 1630 | ≥ 1660 | ≥ 1650 | ≥ 1680 | ≥ 1670 | |

Permanent Linear Change, % | 1500º CX4h, ± 0.2 | 1450º CX2h, ± 0.5 | ||||||

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Classification of chemical components of refractory materialsAccording to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: What role does silica play in refractories?

- The production of clay brick refractory clay raw material is natural, its main mineral is kaolinite (formula Al2O3 - 2SiO2 - 2H2O), clay brick containing SiO2 in 45% ~ 65%, belongs to the weak acid refractory materials, have a certain ability to resist acid slag, but easy to be alkaline slag erosion.

- Q: The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: Brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Silica Brick for Hot-Blast Stoves S-95B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 14 m.t

- Supply Capability:

- 30000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords