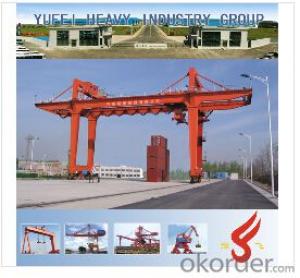

Ship Building Gantry Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ship building gantry crane is a kind of great lifting capacity, large span, high lifting altitude, multi-function, high efficiency of gantry crane, is special for the fragmented transport, end-to-end joint and turning operation of large ship hulls. Ship building gantry crane is used in the place of manufacturing of ship and dock.

In the past ten years, with the development of large-scale ship building, Shipyard gantry crane for sale, ship building gantry crane is the rapid growth of demand. Compared with the traditional portal crane, large ship building gantry crane has the obvious advantage of the installation and transportation of hull sections. It spans the dock (berth), can provide on-site assembly service at the coverage plane in the dock, not only has the lifting, horizontal transport function, but also can implement hull air turnover, adjusting the fragment to the welding position of ship required.

Features:

1. It have multiple functions of single hanging, hoisting, turnover in the air, slight horizontal turnover in the air and so on;

2. The gantry falls into two categories: single girder and double girder. To rationally utilize materials, the girder adopts optimum design of variable section;

3. The gantry rigid legs with a single column and double column type for customer choice.

4. The upper trolley has two main hooks, which are separately fixed at both sides of the main beam, but the lateral movement can be individually or simultaneously 0 - 2m.

5. The lower trolley has a main hook and auxiliary hook, which fixed below at the center of the two girders;

6. Both the upper trolley and the lower trolley can cross each other for operation;

7. All the lifting mechanism and travelling mechanism adopts frequency conversion speed regulating;

8, On the top of the girder at the side of rigid leg is equipped a jib crane to accomplish maintenance of upper and lower trolley;

9. In order to prevent the storm attack, such safe and reliable anti-wind devices as rail clamp and ground anchor are equipped.

Technical Data:

250t×60m | 300t×108m | 600t×60m | |||||

Duty | A5 | ||||||

Lifting weight | Normal lift | t | 250 | 200 | 600 | ||

Rotate lift | t | 200 | 200 | 400 | |||

Span | m | 60 | 108 | 60 | |||

Lifting height | m | 48 | 70 | Above rail 40 Below rail 5 | |||

Top trolley | Lift weight | t | 100×2 | 100×2 | 200×2 | ||

Lifting Speed | m/min | 0.5-5-10 | 0.5-5-10 | 0.4-4-8 | |||

Running speed | 1~28.5 | 3~30 | 1~25 | ||||

Bottom trolley | Lifting weight | Main hook | t | 100 | 150 | 300 | |

Aux hook | 20 | 20 | 32 | ||||

Lifting speed | Main hook | m/min | 0.5-5-10 | 0.5-5-10 | 0.4-4-8 | ||

Aux hook | 10 | 10 | 10 | ||||

Running speed | 1~26.5 | 3~30 | 1~25 | ||||

Jib crane for maintenance | Lifting weight | t | 5 | 5 | 5 | ||

Lifting speed | m/min | 8 | 8 | 8 | |||

Running speed | 20 | 20 | 20 | ||||

Rotate speed | r/min | 0.9 | 0.9 | 0.9 | |||

Crane travelling speed | m/min | 1~26.5 | 3~30 | 1~25 | |||

Max. wheel presure | kN | 200 | 450 | 430 | |||

Power supply | 380V / 10kV; 50Hz; 3 Phase | ||||||

- Q: The construction elevator always jumps

- The starting current is more than three times the running current, and your air switch is low in the maximum current

- Q: Can construction elevators be taken by people or by goods

- According to GB 26557-2011, "a vertical guide for people with vertical navigation". 5.6 lift cage 5.6.1 general When the maximum number of passengers can be carried, the maximum amount of the ceiling shall be calculated according to the area of 0.2 square meters per person, and the weight should be calculated at 75 kg per person.

- Q: Are there any good signs in the construction elevator door

- Above is construction, safety, please stay away from the ground.

- Q: This question asks if a building hoist is capable of lifting objects that vary in size and weight.

- <p>Yes, a building hoist can be used to lift objects of different sizes and weights, but it is crucial to ensure that the hoist's capacity is suitable for the load. Building hoists are designed to handle various materials and equipment during construction, and their lifting capacity can range from a few hundred pounds to several tons. It is essential to check the hoist's specifications and adhere to the maximum load limit to ensure safety and prevent damage to the hoist or the objects being lifted. Always follow the manufacturer's guidelines and safety standards when operating a building hoist.</p>

- Q: Can a building hoist experience failure due to mechanical problems or the natural aging process?

- <p>Yes, a building hoist can malfunction due to mechanical issues or wear and tear. Mechanical problems can arise from various factors such as poor maintenance, overloading, or manufacturing defects. Wear and tear, which is the gradual deterioration of a machine's parts over time, can also lead to malfunctions. Regular inspections and maintenance are crucial to identify and rectify these issues, ensuring the safety and efficiency of the hoist operation.</p>

- Q: The construction of more than many floors must be used for construction elevators

- Elevator drivers must be trained in special safety technology, qualified for examination, and will be on duty. Strict drunken work. The driver must be familiar with the performance, construction, maintenance and maintenance of the elevator, and fill in the mechanical resume and the required reports in time. No inflammable, flammable goods and other sundries shall be piled up in the vicinity of 5m in the construction elevator, and no ditch, pits, or groove shall be dug in this area. The floor feed of the elevator should be set up for protection. When the cage is repaired, if the parts are removed and the weight of the ladder is below the weight, the ladder cage must be locked in the rail. It is strictly forbidden to use the shaft of the construction elevator to support the cable line and other items not related to the elevator. A tower crane or other lifting machine that is built on the same site shall be more than 5m above the elevator and should be properly protected against collision. After the construction elevator is installed, it must be checked and approved by the relevant personnel.

- Q: How to adjust the weight limit of the construction elevator

- It's very simple, there's a couple of buttons down here, okay

- Q: Is it possible to employ a building hoist for demolition purposes?

- <p>While a building hoist is primarily designed for construction purposes, such as lifting materials and personnel to different floors, it is not typically recommended for demolition work. Demolition requires specialized equipment that can handle the specific stresses and hazards associated with breaking down structures. Using a building hoist for demolition could be dangerous and may not comply with safety regulations. It's crucial to use equipment specifically designed for demolition tasks to ensure the safety of workers and the effectiveness of the operation.</p>

- Q: This question asks for the distinctions between two types of building hoists: manual and automatic.

- <p>Manual building hoists require human effort to operate, typically involving a pulley system and manual controls. They are generally less expensive but slower and more labor-intensive. Automatic building hoists, on the other hand, are motorized and can be programmed to lift and lower loads with minimal human intervention. They offer greater efficiency, speed, and safety, but come at a higher cost. Automatic hoists are also more suitable for high-rise construction due to their ability to handle heavier loads and operate over greater distances.</p>

- Q: Whether the construction elevator is a dual-purpose elevator

- Very simple check, the construction elevator is in the construction site, not completely closed, and the human cargo is used commonly in the mall and the factory, is completely closed.

Send your message to us

Ship Building Gantry Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords