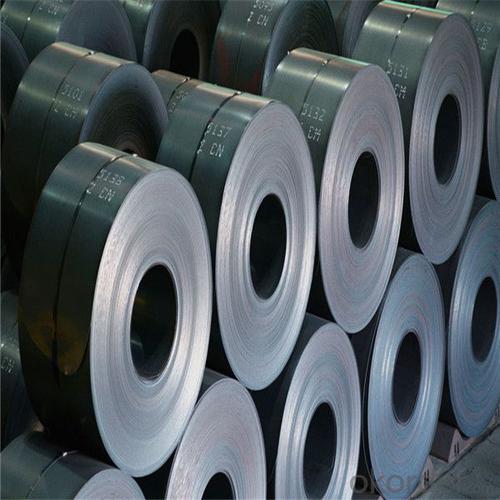

Sheet steel in coil hot rolled for sale in different grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 16792 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot rolled steel actually reconfigures itself during the cooling process, giving the finished product looser tolerances than the original material and when compared to cold rolled steel products. Hot rolled steel is more malleable, allowing it to be forced into a variety of different shapes.

This makes hot rolled steel a good choice for the manufacturing of structural components, such as I beams or simple cross sections, such as rail tracks. It is also used to produce sheet metal.

Our Advantage: High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Standard and Grade :

Hot rolled steel coils | ||||

JIS | ASTM | SAE | EN | |

Commercial quality | G3131 SPHC | A569 A635 A659 A1011 CS Type A,B,C | 1006~1025 |

10111 DD11 |

Drawing quality | G3131 SPHD | 1006~1010 | 10111 DD12 | |

Deep drawing quality | G3131 SPHE | A622 A1011 DS Type A,B | 1006~1010 | 10111 DD13 DD14 |

General structure (T.S.<490N/MM2) | G3101 SS330 SS440 G3106 SM400A G3132 SPHT1 SPTT2 SPHT3 | A36 A283 GR.C A570 GR.30~40 A1001 SS GR.30~40 |

1010~1025 | |

General structure (T.S.≥490N/MM2) | G3101 SS490 G3106 SM490A SM490YA | A570 GR.45~50 A607 GR.45~70 A1011 SS GR.45,50 |

J1392 050X | |

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw

material to final product we have strict quality test;We resolutely put an end to unqualified products

flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: When and where did soldiers wearing steel protective helmets start ?It seems to have been common by the start of WW1

- In WW1 they only wore steel helmets as protection from shrapnel and other debris kicked up by artillery fire. Not protection from bullets oddly enough.

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils play a crucial role in the renewable energy equipment industry by being a key component in the manufacturing of various renewable energy technologies. One of the primary applications of steel coils is in the production of wind turbines. The tower, nacelle, and rotor blades of wind turbines all require steel coils for their construction. In the manufacturing of wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support to the turbine. These coils are typically rolled and welded together to form the tower, ensuring its strength and durability to withstand the forces exerted by the wind. Additionally, steel coils are also used to produce the nacelle, which houses the generator and other essential components of the wind turbine. Moreover, steel coils are used in the production of rotor blades for wind turbines. These blades are responsible for capturing the wind and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength and rigidity to withstand the aerodynamic forces. The coils are often combined with composite materials to optimize the performance and efficiency of the blades. Apart from wind turbines, steel coils are also used in other renewable energy technologies such as solar panels. In the manufacturing of solar panels, steel coils are used to create the frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to efficiently capture sunlight and convert it into electricity. Overall, steel coils are vital in the renewable energy equipment industry as they provide the necessary strength, durability, and structural support to various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector, thereby advancing the global transition towards cleaner and more sustainable sources of energy.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: What are the different methods of recoiling steel coils?

- There are several methods of recoiling steel coils, including the slitting method, the oscillating method, and the rewinding method.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- Elastic Limit Of Steel

- Q: How are steel coils used in the production of infrastructure materials?

- The durability, versatility, and strength of steel coils make them widely used in the production of infrastructure materials. Typically, these coils are made from hot-rolled steel, forming large rolls or coils that are easily transported and handled. One common application of steel coils in infrastructure materials involves producing steel sheets and plates. These coils can be further processed to create flat sheets of steel, which are then utilized in various construction purposes. For instance, steel sheets are frequently employed in manufacturing bridges, highways, and buildings due to their ability to withstand heavy loads and adverse weather conditions. Another important use of steel coils in infrastructure materials is manufacturing pipes and tubes. Steel coils are often processed into seamless or welded pipes that find usage in water and gas pipelines, as well as the transportation of liquids and gases. Infrastructure projects prefer steel pipes and tubes due to their high strength, corrosion resistance, and ability to endure high-pressure environments. Moreover, steel coils are also employed in the production of reinforcing bars or rebars, crucial components in the construction of reinforced concrete structures. These rebars, made from coiled steel, are embedded within concrete to provide tensile strength and enhance the structural integrity of buildings, bridges, and other infrastructure projects. Steel coils enable efficient production of rebars, ensuring consistent quality and size for reinforced concrete constructions. In conclusion, the use of steel coils is essential in the production of infrastructure materials. Their contribution to manufacturing steel sheets, pipes, and rebars ensures the durability, strength, and reliability of infrastructure projects. By providing a versatile and robust material, steel coils contribute to the development of safe and long-lasting structures in our built environment.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This process involves the application of a holographic film or coating onto the surface of the steel coils, creating a visually appealing and unique holographic effect. This coating can be used for various purposes such as branding, security, or aesthetics in industries like automotive, packaging, or electronics.

- Q: How are steel coils used in the shipbuilding industry?

- Steel coils are used in the shipbuilding industry for various purposes such as constructing the ship's hull, decks, and other structural components. These coils are typically cut and shaped to form different sections, plates, or beams that are then welded together to create the ship's framework. Additionally, steel coils are also used for manufacturing equipment, machinery, and other components required for shipbuilding.

- Q: What are the common coil packaging materials?

- The common coil packaging materials include stretch film, shrink wrap, steel strapping, and wooden or cardboard cradles.

- Q: How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings in several ways. Firstly, steel coils are used in the construction of insulated panels and roofs, which provide effective thermal insulation. This insulation helps to reduce heat transfer, keeping the interior of the building cool in hot weather and warm in cold weather. Additionally, steel coils are often used in the manufacturing of energy-efficient windows and doors. These windows and doors are designed to minimize heat loss or gain, thereby reducing the need for heating or cooling systems and saving energy. Furthermore, steel coils are also utilized in the production of energy-efficient appliances, such as refrigerators and air conditioners, which consume less electricity while providing the same level of performance. Overall, the use of steel coils in building construction and appliances contributes to improved energy efficiency, reducing energy consumption and promoting sustainability.

Send your message to us

Sheet steel in coil hot rolled for sale in different grade

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 16792 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords