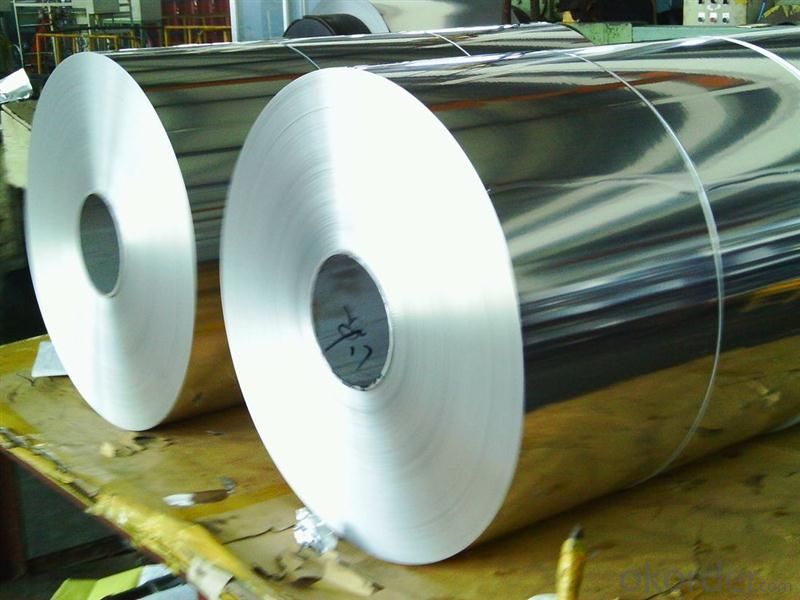

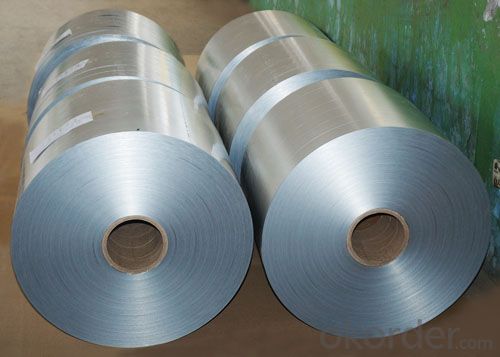

Sheet Aluminum Coil 1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: How do aluminum coils contribute to energy-efficient windows and doors?

- Aluminum coils play a significant role in making windows and doors energy-efficient. Firstly, aluminum is a highly conductive material, meaning it can efficiently transfer heat and cold. This property allows aluminum coils to act as a thermal barrier, preventing the transfer of heat from the outside to the inside and vice versa. By minimizing heat transfer, aluminum coils help to reduce the amount of energy needed to cool or heat a building, resulting in lower energy consumption and reduced utility bills. Additionally, aluminum coils are often used in the construction of window and door frames due to their lightweight and durable nature. This lightweight property makes it easier to install and operate windows and doors, while their durability ensures long-lasting performance. The use of aluminum coils also allows for the creation of sleek and narrow frame designs, maximizing the glass area and allowing more natural light to enter the building. This reduces the need for artificial lighting during the day, further contributing to energy savings. Moreover, aluminum is a highly recyclable material, and the use of aluminum coils promotes sustainability. By using recycled aluminum to manufacture these coils, energy-efficient windows and doors can be created with a lower carbon footprint. This reduces the environmental impact of the building industry and contributes to a more sustainable future. In conclusion, aluminum coils contribute to energy-efficient windows and doors through their thermal barrier properties, lightweight and durable nature, and recyclability. By minimizing heat transfer, facilitating efficient installation, and reducing the use of artificial lighting, aluminum coils play a key role in creating sustainable and energy-saving building solutions.

- Q: What is the maximum coil weight for aluminum coils?

- The maximum coil weight for aluminum coils can vary depending on various factors such as the thickness and width of the coil, as well as the specific alloy being used. Generally, the maximum coil weight for aluminum coils ranges from around 5,000 to 25,000 pounds. However, it is important to note that these figures are approximate and can differ depending on the manufacturer's guidelines and equipment capabilities. Additionally, it is always recommended to consult the manufacturer or supplier for specific coil weight limitations to ensure safe handling and transportation.

- Q: What are aluminum coils?

- Aluminum coils are long, flat strips of aluminum that have been rolled up into a cylindrical shape. They are commonly used in various industries, including automotive, construction, and HVAC, for their excellent heat conductivity and corrosion resistance properties. These coils can be further processed and fabricated into different products such as roofing materials, heat exchangers, and electrical wiring.

- Q: How do aluminum coils contribute to sustainable transportation systems?

- Aluminum coils contribute to sustainable transportation systems by being lightweight, durable, and recyclable, which helps reduce the overall weight of vehicles, resulting in improved fuel efficiency and reduced emissions. Additionally, the recyclability of aluminum coils promotes a circular economy, minimizing waste and conserving resources.

- Q: What is the typical coil width for aluminum coils?

- The specific application and industry determine the typical coil width for aluminum coils. Generally, it can range from a few inches to several feet. In the construction, automotive, and packaging industries, common coil widths typically range from 12 to 72 inches. These widths are chosen based on manufacturing process requirements, final product dimensions, and coil processing equipment. It is important to mention that customer needs and the aluminum coil manufacturer's production capabilities may lead to customized coil widths.

- Q: Is it advisable to purchase and utilize recycled aluminum coils without initial quality assessment?

- <p>No, it is not safe to buy and use recycled aluminum coils without first checking their quality. Recycled aluminum coils may have inconsistencies in thickness, strength, and purity, which can affect the performance and safety of the final product. It's crucial to inspect the coils for any defects, impurities, or deviations from the required specifications to ensure they meet the standards necessary for your application. Quality control is essential to prevent failures, maintain safety, and uphold the integrity of your manufacturing process.</p>

- Q: I live around Minneapolis, MN. Is there a place that you can recycle crushed aluminum cans for money around here?

- Probably there are scrap metal companies in most major cities. It takes a lot of cans to make any money at it though .

- Q: What are the different coil annealing options available for aluminum coils?

- For aluminum coils, there are multiple options for coil annealing, depending on the desired outcome and requirements. 1. Full Annealing: To achieve a soft and fully recrystallized structure, the aluminum coil is heated to a specific temperature and then slowly cooled down. This process helps relieve internal stresses, improve ductility, and enhance the mechanical properties of the coil. 2. Solution Annealing: This method is primarily used for heat-treatable aluminum alloys. It involves heating the coil above the alloy's solvus temperature and then rapidly cooling it. By doing so, any alloying elements are dissolved and redistributed, resulting in a homogenous microstructure. 3. Stabilization Annealing: Certain aluminum alloys undergo stabilization annealing to enhance dimensional stability and reduce the risk of distortion during subsequent processing or usage. The coil is heated to a temperature slightly below the alloy's recrystallization temperature and then slowly cooled. 4. Stress Relief Annealing: This type of annealing is performed to relieve residual stresses that may have developed during previous manufacturing processes. By heating the coil to a specific temperature and holding it there for a certain duration, the stresses are allowed to relax. This improves the coil's formability and minimizes the risk of deformation during subsequent operations. 5. Intermediate Annealing: During the manufacturing process, intermediate annealing is used to restore the ductility and formability of the aluminum coil. The coil is heated to a temperature below the recrystallization temperature and then undergoes a controlled cooling process. This eliminates any work hardening that may have occurred during previous operations. These are just a few of the common coil annealing options available for aluminum coils. The choice of annealing method depends on factors such as the alloy composition, intended application, and desired material properties. It is advisable to consult with experts or heat treatment professionals to determine the most suitable annealing method for a particular aluminum coil.

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- When it comes to durability, aluminum coils outperform plastic coils. Aluminum is renowned for its strength and ability to resist wear and tear, making it a highly durable material. It can withstand heavy usage without cracking, breaking, or deforming under pressure. In contrast, plastic coils are more susceptible to damage, particularly with repetitive use or extreme temperatures. Although plastic coils may be cost-effective and lightweight, they may not maintain their quality over time. Consequently, for those prioritizing durability, aluminum coils are the superior option due to their longer lifespan and increased resistance to damage.

- Q: Is it possible to utilize aluminum coils for the purpose of storage?

- <p>Yes, aluminum coils can be used for storage, particularly in industrial settings. They are often used for storing materials such as paper, plastic films, and other coilable products. Aluminum coils are lightweight, corrosion-resistant, and can be easily transported and handled. They are also recyclable and environmentally friendly. However, their suitability for storage depends on the specific application and the type of material being stored. It's important to ensure that the coils are stored in a dry, clean environment to prevent damage and maintain their integrity.</p>

Send your message to us

Sheet Aluminum Coil 1100 Temper H18 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords