Semi-Auto Straw Baler, Rice Straw Baling Machine, Coconut Fiber Baler Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

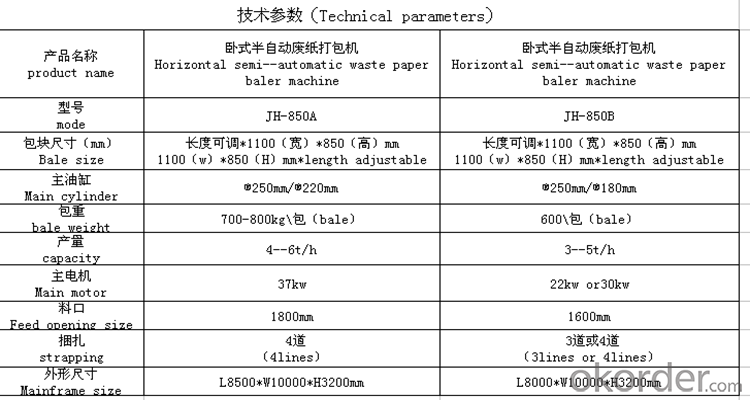

Specification

Product Application

The waste paper baler machine is used for extruding and forming the waste paper and the similar products in the normal condition,and use the special packing belt bale forming ,make its volume greatly reduced,so as to cchieve the purpose of reducing the volume of transport,saving freight and increasing the efficiency of the enterprise . introducing advanced technology of similar products at home dad abroad.

Name: line

All bearings, pairs of motion, guide rails, etc. shall be provided with lubrication refueling points, and have a prominent logo. Lubrication points that are not convenient for direct refueling shall be led to corresponding lubrication lines and refueling points, and be placed in a safe and convenient place for

Name: system

1、The device has alarm indicator, fault display and prompt function

2、Cooling tower cooling system is adopted so that the equipment can maintain normal operation below 60° for a long period of time;

3、Lubrication system: automatic lubrication system reduces mechanical wear, reduces mechanical noise, and stabilizes mechanical operation.

Name: Fixed pressure package

Fixed pressure package length: high strength train rail joint structure; and timer control package length.

Name: Bliwing Cylinder

Name: Bliwing Cylinder

1、Stranding mechanism: gear transmission, hydraulic winding; shred.

2、Wire tie method: hydraulic hook line, trimming system, and 3 lines.

3、Bottom structure: roller track, track with wear-resistant high-quality steel 20mm. Bottom support ribs 180 GB channel.

4、Pushing system: roller device, reducing the mechanical resistance of the main hydraulic cylinder return movement, effectively increasing the speed of pushing the package. The composition of the pusher head is welded from 20mm pure steel plate with a rib thickness of 20mm.

5、Fixed pressure package length: high strength train rail joint structure; and timer control package length.

6、Lubrication system: automatic lubrication system reduces mechanical wear, reduces mechanical noise, and stabilizes mechanical operation.

Our Service

Pre-Sales Service

1.Your inquiry will be replied within 24 hours.

2.Any questions, you could email us or call directly.

3.24 hours technical support by e-mail.

After-Sales Service

One year guarantee period after installation.

During this guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, we will provide them at cost price.

process

Waste paper bins, scraps, etc. are manually collected or conveyed by conveyor belts onto the feeding conveyor belt. The feeding conveyor belt conveys these materials to the host compression chamber. When the material reaches a certain height, the main cylinder drives the pressure plate to move forward. When compressing the material, when it reaches the front end, the main oil cylinder is reset backwards and waits for feeding. When the material is full and reaches a certain height, the main oil cylinder drives the pressure plate forward to compress the material and repeat the above process. When the compressed material reaches the set length, the pressure plate will stop at the front end and will not be reset afterwards. The hooking machine will stop when it moves forward to the extreme end, and the hooking machine will move backward to start the hooking line work. At the end of work, push the tank cylinder to work, push the wire and thread trimmer forward to the working position, work on the bundled wire motor, start the bundled wire, and after the bundled wire is completed, stop the bundled wire, trim the cylinder work, and cut the bundled bundle. Iron wire. Push tank cylinder reset, the main cylinder reset, a work process is completed. The above working process is completed automatically by the PLC intelligent control, and the entire process of feeding, compressing, hooking, binding, trimming, and packaging is automated. Touch screen control, good man-machine interface, whole process safety monitoring, failure, safety detection alarm, display function. Full hydraulic drive, stable operation, easy control and low failure rate.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- In today's world, the upgrading of packaging machinery and equipment and production lines are far ahead of Japan, which has earned a large number of dollars in this field. Southeast Asian Four Dragons also follow Japan, a heart in the performance of manufacturing packaging machinery equipment and production lines; in the European community, Italy packaging machinery equipment and production line upgrading faster than other members faster.Renewal is the means of replacing the local parts and components or key components and key technologies, so as to achieve the replacement of one of the unit, so that the original packaging machinery equipment or production line production capacity, performance, efficiency, and assembly way of updated models. In this way, most parts and machine parts are reused, which can improve the equipment value, save the raw materials and the labor force, and reduce the cost. This development trend shows that the packaging machinery, equipment and production lines are becoming more and more standardized, serialized, integrated, integrated and on-line. Civilian, military and high technology will also be more and more widely used in the field of packaging machinery equipment. Fierce market competition will undoubtedly speed up the upgrading of packaging machinery and equipment in all walks of life and technological transformation.

- Q: What is the price of a small jujube packing machine?

- Mainly see what some requirements, automatic metering packaging or vacuum packaging machine, after understanding can determine the price.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: What's the fastest packing machine?

- 3 ideal speed of the package can reach 70 packs, that is, 70*3 = 210., and now there are 4 packages abroad. But the bags are small.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Graphic symbols for packaging and storageGB/T 5009.60. Analytical method for hygienic standard of polyethylene, polystyrene and polypropylene moldings for food packaging

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

Send your message to us

Semi-Auto Straw Baler, Rice Straw Baling Machine, Coconut Fiber Baler Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 300 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords