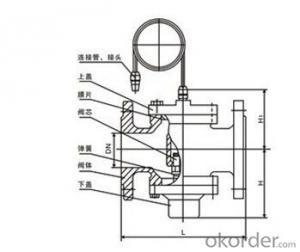

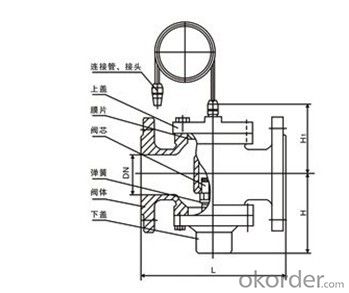

Self-operate differential pressure control valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Size: DN15-DN400

Nominal Pressure: PN10/PN16

Operation Temperature: 0°C~150°C

Suitable Medium: Water,Steam

2.Feature

ZYC self-reliance type differential pressure control valve is a kind of self control USES the pressure of medium changes and keep unchanged through the control system in the medium pressure difference of energy-saving products. Applicable to the heating mode adopts double pipe system of differential pressure control, to ensure that the system pressure difference basically remain unchanged, reduce noise and balance the resistance, eliminating heat supply network hydraulic disorder.

- Q: Z11H/Y forged steel gate valves H/Y what does that mean?SZ45H S what do you mean?Blow 2Z41YGY-40P, what do you think?What does NKZ61H vacuum valve NK mean?What does DS/Z64H water seal valve DS mean?Specific valve number how to see ah, detailed information, thank you!

- The meaning of valve number:Valve type Z, J, L, Q, D, G, X, H, A, Y and S respectively: gate valve, globe valve, throttle valve, ball valve, butterfly valve, diaphragm valve, plug valve, check valve, safety valve, relief valve, drain valve.The connecting codes for valves are 1, 2, 4, 6, 7, respectively: internal thread, 2, outer thread, 4, flange, 6, welding, 7, pair.Valve transmission mode code 9, 6, 3, respectively, said: 9, electric, 6, pneumatic, 3, turbo worm.Body material Z, K, code Q, T, C, P, R and V respectively: grey cast iron, malleable cast iron, ductile iron, copper and alloy, carbon steel, stainless steel, chrome nickel chromium nickel molybdenum stainless steel, chromium molybdenum vanadium steel.Seat sealing or lining R, T, X code, S, N, F, H, Y, J, M, W respectively: austenitic stainless steel, copper alloy, plastic, rubber, nylon plastics, fluorine plastic, Cr stainless steel, hard alloy, rubber lining, Monel alloy, valve body material.

- Q: What does the J41Y-100I valve type mean?

- J41Y-100I flange type chrome molybdenum steel valve forgingJ represents the cut-off valve, 4 (flange) on behalf of his connections, 1 (straight) on behalf of his structure, Y (seal) on behalf of his seat sealing surface or liner material code, 100 is the nominal pressure value, I (chrome molybdenum steel) is the code of the body material

- Q: Valve connections - two how do different connections work?

- The connection of two different connection forms is achieved by a transition conversion connector

- Q: What kind of valve is it? How do you see the status of the switch?

- This is a ball valve, that is, usually said cut-off valve, to determine the switch state is carefully look at, there is a switch on the status of the arrow, you will understand.

- Q: What are the other valves used for the control of dual-use items?

- The coding needs to do export dual-use items technical license, this is to go to Beijing for approval for 1 months, I have the electronic key for you to handle, you can also charge electronic keys

- Q: Air compressor out of the gas with what kind of valve control okay, globe valve or other?

- Air compressor all copper safety valve (AQ-20) (AQ-25)Air compressor, air release valve and so on. The air compressor rated exhaust pressure is divided into low pressure (0.7~1.0MPa), medium pressure (1.0~10MPa), high pressure (10~100MPa) and ultra high pressure (100MPa or more), to see what kind of installation you are and use

- Q: Representation of several types of valves

- Valve body material:Z grey castings (usually not shown)X malleable ironQ nodular cast ironT copper alloyB lead alloyII chromium molybdenum alloy steelL chrome alloyP chromium nickel steelV (II) chromium molybdenum vanadium alloy steelR cr.ni.mo.ti steelF fluoroplasticP leather (Shen Penggang)S plasticD nitrided steelCJ lining adhesiveTC magnetic boringCS lined plasticCQ lined with leadW sealing ring is machined from valve body, C carbon steel (generally not shown)G ferrosilicon

- Q: How much is the 150LB of the valve?

- 150Lb=2.0MPa=20 kg.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications.

- Q: What are the key valve enterprises in China? Mainly in those areas?

- Chinese valve is mainly produced in Zhejiang, where Wenzhou, Shanghai there are a lot of Zhejiang valve in Wenzhou, but also Shanghai valve production, many are also Zhejiang boss, the key depends on whether you need what valve valve, the valve may be located in different regions is not the same

- Q: What's the difference between a valve and a valve?

- The correct unit should be called "group". A set of threaded valves include valves, live connections, and short tubes. A set of flanged valves consist of a pair of flanges (including bolts, gaskets, rubber pads), and short tubes".

Send your message to us

Self-operate differential pressure control valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords