Geogride Stragrip Sg-150 Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

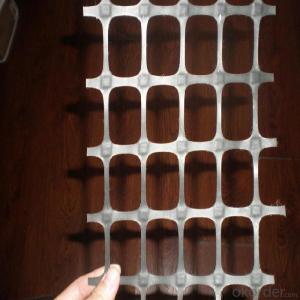

Structure of Self-Adhesive Fiberglass Geogrid Description:

Self-Adhesive Fiberglass Geogrid can be used to enhancement of permanent bearable toft including roads and railways embankment, slopes, tunnel, airfields, parks, docks and ground which cargo lays on and their main usage

Main Features of Self-Adhesive Fiberglass Geogrid:

1.Enhance the bearing capacity of road foundation and extend the duration of roads.

2.Prevent road surface from collapse, crack and being dirty.

3.Be convenient for construction, timesaving and cut down the cost of maintenance.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

6.Reduce the surface thickness of the ground.

Self-Adhesive Fiberglass Geogrid Images

Self-Adhesive Fiberglass Geogrid Specification:

Item | TGSG15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | |||||

Unit | MD | CD | MD | CD | MD | CD | MD | CD | |

True initial Modulus in Use | KN/m | 15 | 15 | 20 | 20 | 30 | 30 | 40 | 40 |

True Tensile Strength @2% Strain | KN/m | 5 | 5 | 7 | 7 | 11 | 11 | 16 | 16 |

True Tensile Strength @5% Strain | KN/m | 7 | 7 | 14 | 14 | 21 | 21 | 32 | 32 |

Junction Efficiency | % | 100 | 100 | 100 | 100 | ||||

Flexural Stiffness | mg-cm | 280.000 | 780,000 | 900,000 | 1,200,000 | ||||

Aperture Stability | kg-cm/deg | 3.1 | 4.8 | 4.3 | 3.4 | ||||

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | ||||

Resistance to Long Term Degradation | % | 100 | 100 | 100 | 100 | ||||

Unit Weight | g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | ||||

Rolls Dimensions (Length, Width) | m | 50×3.95 | 50×3.95 50X5 | 50×3.95 | 50×3.95 | ||||

Lading Capacity | Rolls/40HC | 300 | 260 | 140 | 100 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Glass fiber grille is not geogrid

- Yes, one of the three categories of geogrid. Fiberglass grille is another kind of glass fiber geogrid.

- Q: What is the difference between woven and non-woven geogrids?

- Woven geogrids are made by weaving individual yarns together, creating a grid-like structure. Non-woven geogrids, on the other hand, are manufactured by bonding or interlocking fibers together through mechanical, thermal, or chemical processes. The key difference is in the manufacturing process, which results in woven geogrids being stronger and more rigid, while non-woven geogrids tend to be more flexible and have higher tensile strength. Additionally, woven geogrids are generally used in applications that require high load-bearing capacity, while non-woven geogrids are often used for soil stabilization and separation purposes.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in sandy soils?

- Geogrids improve the performance of mechanically stabilized slopes in sandy soils by providing reinforcement and increasing the stability of the soil. They help distribute tensile forces and reduce lateral movement, preventing slope failure. Additionally, geogrids enhance the bearing capacity of the soil, allowing for higher loads and reducing settlement.

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and enhance the stability of the soil, reducing the risk of embankment failure. By distributing loads and increasing the bearing capacity of the soil, geogrids help to prevent settlement and movement, ensuring the long-term stability of the embankment for pipeline crossings.

- Q: Can geogrids be used in retaining walls for highway projects?

- Yes, geogrids can be used in retaining walls for highway projects. Geogrids are commonly used in such projects to reinforce soil and provide stability to the retaining walls. They enhance the overall strength and durability of the walls, making them a reliable choice for highway construction.

- Q: Can geogrids be used in bridge abutment reinforcement?

- Yes, geogrids can be used in bridge abutment reinforcement. Geogrids are commonly used in civil engineering projects to enhance soil stability, prevent soil erosion, and provide reinforcement. They can be used to reinforce the backfill material behind bridge abutments, improving their overall stability and load-bearing capacity.

- Q: Are geogrids suitable for reinforcement of mechanically stabilized aggregate base layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate base layers. Geogrids are designed to improve the strength and stability of soil or aggregate layers by distributing loads more efficiently and reducing lateral movement. They can enhance the performance and lifespan of mechanically stabilized aggregate base layers by increasing their load-bearing capacity, reducing rutting, and preventing the formation of cracks.

- Q: How thick is the need to lay a layer of Geogrid in the new highway earthwork backfill? Specific foundation to pave the way to solve

- The road at the interface, and the next day than the Square Street shop

- Q: Can geogrids be used in mining and geotechnical applications?

- Yes, geogrids can be used in both mining and geotechnical applications. In mining, geogrids can be used for reinforcement and stabilization of slopes, mine walls, and tailings dams. They can also be used for erosion control and soil stabilization during excavation and reclamation activities. In geotechnical applications, geogrids are commonly used for soil reinforcement, retaining walls, embankments, and pavement construction to improve the stability and load-bearing capacity of the soil.

- Q: Fiberglass grille and geogrid which use more

- Geogrid is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as civil engineering, called geogrid.

Send your message to us

Geogride Stragrip Sg-150 Self-Adhesive Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords