Polypropylene Geogrids - Corrosion Resistant Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

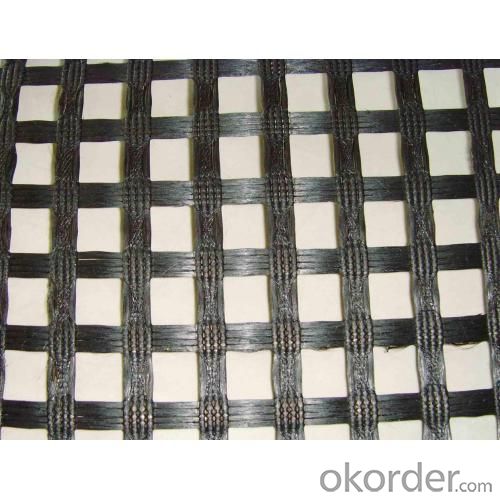

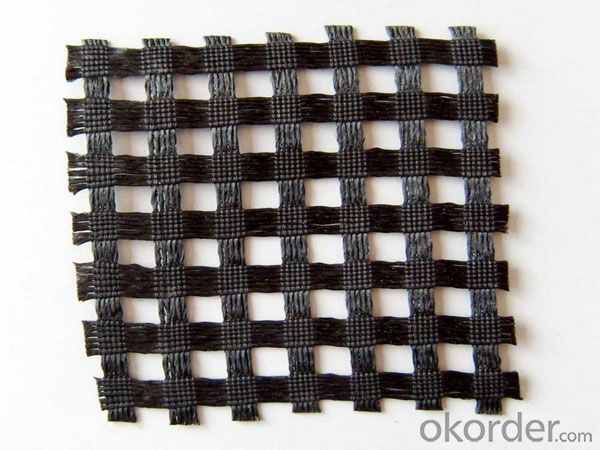

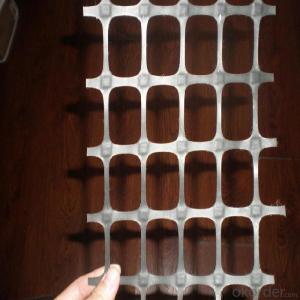

Structure of Corrosion Resistant Fiberglass Geogrid Description:

Corrosion Resistant Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.Used for engineering reinforcement,10%,13% elongation,50x50mm holes size.

Main Features of Corrosion Resistant Fiberglass Geogrid:

Fiberglass Geogrid Improve roadbed bearing capacity,enlarge road lifetime.

Prevent road collapse and crack

Fiberglass Geogrid maninly applied in strengthen soft ground of rail and road

Could replace steel-plastic geogrid in coal mine.

Corrosion Resistant Fiberglass Geogrid Images

Corrosion Resistant Fiberglass Geogrid Specification:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used for reinforcement in soft soils?

- Yes, geogrids can be used for reinforcement in soft soils. Geogrids are commonly used in geotechnical engineering to improve the stability and strength of soft soils. They provide additional tensile strength and distribute loads more evenly, reducing settlement and improving overall performance in soft soil conditions.

- Q: Who has the "highway geosynthetics geogrid" specification

- The first part of Geogrid

- Q: How do geogrids affect soil compaction?

- Geogrids help to improve soil compaction by providing reinforcement and stability to the soil. They distribute the load more evenly, reducing the risk of settlement and improving overall soil strength. Additionally, geogrids enhance the interlocking behavior of soil particles, increasing the soil's resistance to shear forces and minimizing lateral movement.

- Q: How do geogrids enhance the performance of geocell confinement systems?

- Geogrids enhance the performance of geocell confinement systems by providing additional reinforcement and stability. They are integrated within the geocell walls, creating a stronger structure that can withstand higher loads and pressures. Geogrids also distribute the applied forces more evenly, preventing localized stress concentrations and reducing the risk of deformation or failure. Ultimately, the use of geogrids improves the overall performance and longevity of geocell confinement systems.

- Q: What are the environmental impacts of using geogrids?

- The environmental impacts of using geogrids can vary depending on factors such as the type of material used, manufacturing processes, and disposal methods. However, some potential impacts include the extraction of raw materials, energy consumption during manufacturing, and the generation of waste and emissions. It is important to consider these factors and ensure proper management and disposal practices to minimize the environmental impacts of using geogrids.

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are typically resistant to acid degradation.

- Q: What is the difference between geogrids and geotextiles?

- Geogrids and geotextiles are both used in civil engineering and construction projects for soil stabilization and reinforcement, but they differ in their structural composition and primary functions. Geogrids are typically made of high-strength polymers or metals and have a grid-like structure. They are designed to provide tensile strength and stiffness to soils by interlocking with soil particles. Geogrids are commonly used in applications where there is a need for load distribution, such as retaining walls, embankments, and roadways. On the other hand, geotextiles are made of woven or non-woven fabrics and are primarily used for filtration, drainage, and separation of soil layers. Geotextiles allow water to pass through while preventing soil erosion and the mixing of different soil layers. They are frequently employed in applications like erosion control, sedimentation prevention, and drainage systems. In summary, geogrids provide structural support and strength to soils, whereas geotextiles primarily serve as barriers for filtration, separation, and erosion control.

- Q: What is the effect of aging on geogrid properties?

- The effect of aging on geogrid properties is generally a decrease in mechanical strength and stiffness. Over time, exposure to environmental factors such as sunlight, temperature variations, and moisture can cause degradation of the geogrid material, leading to reduced tensile strength, increased elongation, and diminished load-bearing capacity. The aging process can also result in changes to the geogrid's chemical composition and surface morphology, impacting its ability to interlock with surrounding soil particles and retain its original design characteristics. Therefore, it is crucial to consider the potential effects of aging when designing geogrid-based structures and to periodically assess their condition to ensure their long-term performance.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to first prepare the subgrade by removing any vegetation or loose soil, and then compact the subgrade to achieve a stable base. The geogrid should be unrolled and placed on top of the prepared subgrade, ensuring it is stretched and anchored securely at the edges. Overlapping the geogrid panels by the manufacturer's recommended amount and using connector devices may be necessary. Finally, the geogrid should be covered with an appropriate fill material and compacted in layers to ensure proper integration and load distribution.

- Q: What are the factors to consider in selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, there are several factors to consider. These include the type of soil and its properties, the expected loads and stresses on the geogrid, the desired design life and durability, the installation and construction methods, and any specific requirements or regulations for the project. Additionally, the cost and availability of the geogrid, as well as the supplier's reputation and technical support, should also be taken into account.

Send your message to us

Polypropylene Geogrids - Corrosion Resistant Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords