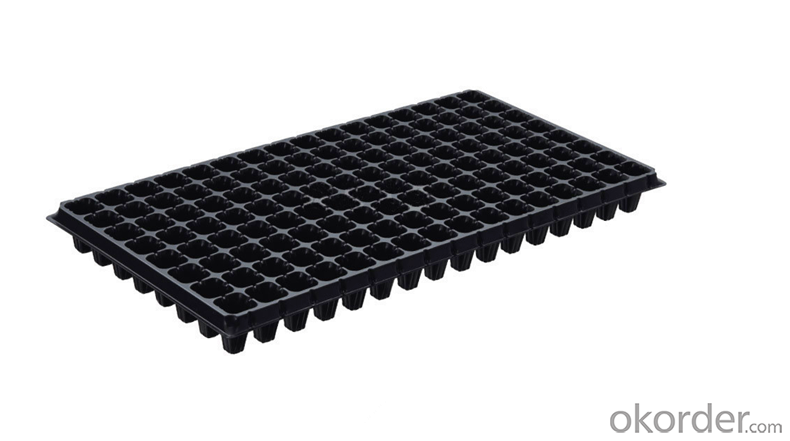

Seed Tray Greenhouse Usage Plug Trays HIPS Made Plastic (Growing and Seedling)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction to CNBM:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Features of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

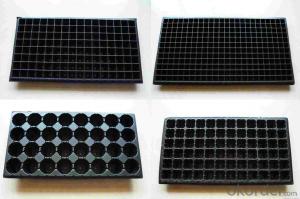

Picture:

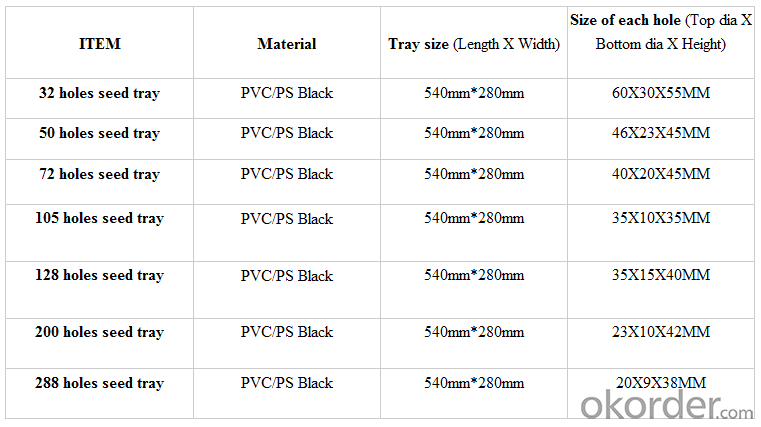

Specification of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

FAQ of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

Q:1.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

Q: 2.How long is the production time?

A: Usually one to two weeks.

Q: 3.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

- Q: We have to much plastic and not enough energy - is it possible to turn plastic INTO energy?

- start it on fire, and the smoke could power tiny little windmills that turn windpower into electricity:D

- Q: What are some ground cover options for alkaline soil?

- Some ground cover options for alkaline soil include creeping phlox, yarrow, sedum, creeping juniper, and lamb's ear.

- Q: Can nursery trays be used for starting a vegetable patch?

- Yes, nursery trays can be used for starting a vegetable patch. These trays provide a convenient way to germinate seeds and nurture seedlings before transplanting them into the ground. They are designed to provide optimal conditions for seedlings, such as proper drainage and a controlled environment. Using nursery trays can help ensure successful germination and early growth of vegetable plants, giving them a head start before being planted in the garden.

- Q: Can agricultural plastic products be used for mulching?

- Yes, agricultural plastic products can be used for mulching. Mulching with agricultural plastic products helps to control weed growth, conserve moisture, regulate soil temperature, and prevent erosion. It is a common practice in agriculture to use plastic mulch films or biodegradable mulch films made from agricultural plastic products to enhance crop growth and yield.

- Q: Are agricultural plastic products used in organic pest control methods?

- No, agricultural plastic products are not typically used in organic pest control methods. Organic pest control methods focus on natural and environmentally friendly approaches, such as crop rotation, companion planting, and biological controls. The use of plastic products contradicts the principles of organic farming and is more commonly associated with conventional farming practices.

- Q: How does ground cover impact the growth of nearby bulbs?

- Ground cover can have both positive and negative impacts on the growth of nearby bulbs. On one hand, a thick and dense ground cover can provide shade, reduce soil moisture evaporation, and protect bulbs from extreme temperatures, leading to more favorable growing conditions. On the other hand, if the ground cover is too dense, it can outcompete bulbs for nutrients and water, limiting their growth and survival. Therefore, the specific type and density of ground cover are important factors to consider for the successful growth of nearby bulbs.

- Q: My persian cat ate the plastic wrapper from a juice box straw is he gonna be okay? At first I thought he was playing with it so I left him alone but then he ate it! Is he going to be okay? ):

- Its sure not safe for anyone even us to eat plastic, keep an eye on her for sure to see if she has problems passing her bowel movements. Also to be safe call you VET monday morning and ask her this is a question they need to answer.. I sure wouldn't trust anyone Else's answers with out a solid back up.. you know? GOOD LUCK

- Q: Can agricultural plastic products be used for trellising?

- Yes, agricultural plastic products can be used for trellising. They are often used as a cost-effective and durable alternative to traditional materials like wood or metal. Agricultural plastic products, such as trellis netting or plastic stakes, provide support for climbing plants and help optimize their growth and yield.

- Q: What is a nursery tray?

- A nursery tray is a shallow container used for starting and growing seeds or seedlings. It provides a controlled environment for the plants, allowing them to develop strong root systems before being transplanted into larger pots or the ground.

- Q: I Been Looking For Years On How To Do Make Make Plastic//Lucite Jewelry Like This.

- Lucite is a particular type of plastic, but you can purchase epoxy resin at most any hardware store. Mix the two together and pour into a form, you will have plastic. Using more or less hardener will produce different results. Color is added separately. These types of plastics are generically called chemo-set, or chemically hardened. Alternatively, many plastics are thermo-set and basically melt or become fluid at higher temperatures and then set up, or harden, at lower temperatures. Plastic soda bottles are of this sort.

Send your message to us

Seed Tray Greenhouse Usage Plug Trays HIPS Made Plastic (Growing and Seedling)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords