Plug Trays (Growing and Seedling) Greenhouse Usage HIPS Made Plastic Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction to CNBM:

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

Features of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Picture:

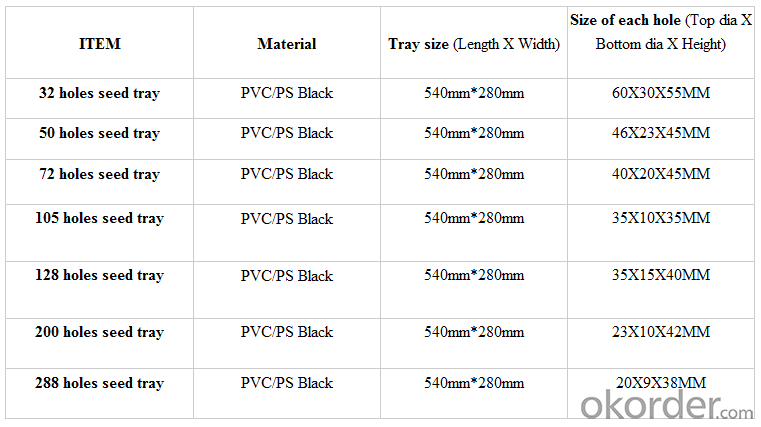

Specification of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

FAQ of Plug Trays (Growing and Seedling) HIPS Made Plastic Plug Tray for Greenhouse:

Q:1.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

Q: 2.How long is the production time?

A: Usually one to two weeks.

Q: 3.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

- Q: Can agricultural plastic products be used in agroforestry?

- Yes, agricultural plastic products can be used in agroforestry. Agroforestry involves the integration of trees and agriculture, and plastic products can serve various purposes in this system. For example, plastic mulch films can be used to control weeds, conserve moisture, and regulate soil temperature, enhancing tree and crop growth. Plastic tree guards or tubes can protect young saplings from pests and provide a controlled microclimate for their development. Additionally, plastic irrigation pipes or drip systems can efficiently deliver water to both trees and crops, ensuring their optimal growth and productivity in agroforestry systems.

- Q: Describe how farmers utilize agricultural plastic tarps to shield crops from adverse weather conditions.

- <p>Farmers use agricultural plastic tarps to protect crops from rain and wind by covering the crops with the tarps, which act as a barrier against the elements. These tarps are made of durable materials that can withstand rain and wind, preventing water from directly hitting the plants and reducing wind damage. They are often used in conjunction with a framework of poles or hoops to create a tunnel-like structure over the crops. This not only shields the plants from rain and wind but also helps in maintaining temperature and humidity levels, promoting optimal growing conditions. In some cases, farmers might also use the tarps to cover the soil to prevent erosion and retain moisture, indirectly protecting the crops by preserving the quality of the soil.</p>

- Q: I broke my plastic one and was wondering. I know the aluminum block is more durable but it cost about 35$, the plastic one is weaker but it cost 3$. Is the aluminum block worth the by or should i go for the cheap plastic one. Please Help!

- If you don't mind replacing it once in a while go for the cheap one.

- Q: This question asks for an explanation of the method by which farmers utilize plastic mulch film in agriculture to combat soil salinity.

- <p>Farmers use agricultural plastic mulch film to prevent soil salinity by covering the soil surface with the film. This practice reduces soil evaporation, thereby decreasing the amount of salt that is drawn to the surface through capillary action. The film also helps to retain soil moisture, which can dilute the salt concentration. Additionally, it can improve the efficiency of water and nutrient use by directing water directly to the plant roots, reducing the overall water needed and thus limiting the potential for salt buildup. By controlling the microclimate around the plant, plastic mulch film can also enhance the overall health of the crop, making it more resilient to soil salinity issues.</p>

- Q: Can ground cover plants be used to create natural weed barriers?

- Yes, ground cover plants can be used to create natural weed barriers. Ground cover plants such as creeping thyme, creeping juniper, or vinca minor form dense mats that effectively suppress the growth of weeds. These plants cover the soil, blocking sunlight and preventing weed seeds from germinating. Additionally, ground cover plants have shallow root systems that compete with weeds for nutrients and moisture, further reducing weed growth.

- Q: Can nursery trays be used for starting ground orchids?

- Yes, nursery trays can be used for starting ground orchids. They provide a convenient and organized way to sow orchid seeds or propagate orchid plants. The trays help maintain the necessary moisture levels and are designed to promote healthy root development.

- Q: Can I use a plastic turkey baster to suck up hexane without it melting?

- You asked the question correctly Will hexane dissolve plastic? - and then you used the term melting Melting implies a change of state from sold to liquid upon application of heat - something dissolving and something melting are NOT the same. Do not confuse the terminology! Also, be very careful about the term plastic. There are huge numbers of different synthetic polymers all of which can be regarded as plastics and all of which have specific properties. Simply referring to plastic is a bit like saying we're having food for dinner tonight ! In the case of hexane, however, it is relatively innocuos and doesn't act as a solvent for most common synthetic polymers under normal conditions. So you should be OK, although a glass pipette would be preferable!

- Q: Can nursery trays be used for growing ground orchids?

- Yes, nursery trays can be used for growing ground orchids. Nursery trays provide a suitable environment for starting ground orchids from seeds or propagating them from divisions. They allow for proper drainage and provide a controlled space for the orchids to establish their root systems. Additionally, nursery trays can be easily moved or rearranged to optimize sunlight and air circulation for the plants.

- Q: I bought some fine silver bars and they came in plastic. Will the silver lose value if I take it out of the plastic?

- no- they will loose value if the market goes down.

- Q: Can nursery trays be used for starting native grass seeds?

- Yes, nursery trays can be used for starting native grass seeds.

Send your message to us

Plug Trays (Growing and Seedling) Greenhouse Usage HIPS Made Plastic Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords