Seamless Steel Pipe ASTM A106, ASTM A53, ISO3183-2-1996 GB3087 China Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B description:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell.

As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable.

Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Features :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Standard :GB5310: Seamless Steel Tubes And Pipes for High Pressure Boiler

● Application: For manufacture heating-pipelines, containers, coal-saving devices, super heaters and reheaters

of high pressure boilers(P>9.8Mpa,450℃

after consulting with customers.

4、Packaging & Delivery of CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

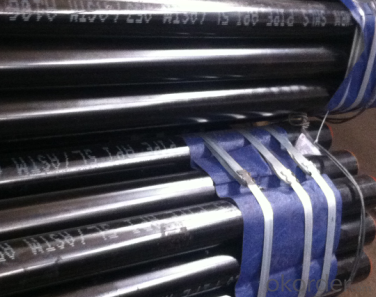

CS SEAMLESS PIPE ASTM A53/ ASTM A106/ API 5L GR B Images:

FAQ of Seamless Pipe ASTM A106/53:

①Quality

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②Price

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

Why us?

Professional teams ensure a high efficiency of your purchase

▲ Professional sales team

▲ Professional engineering and technology team

▲ Professional exportation and contract processing/management team

▲ Professional cooperators and partners

Looking forward to doing the corporation with you

Any question, kindly feel free to contact us !

- Q: How are steel pipes used in the construction of buildings?

- Steel pipes are commonly used in the construction of buildings for various purposes. They are primarily used for structural support, providing stability and strength to the overall framework. Steel pipes are also used for plumbing systems, carrying water and other fluids throughout the building. Additionally, they are used for HVAC (heating, ventilation, and air conditioning) systems, allowing for efficient distribution of air. Overall, steel pipes play a crucial role in ensuring the durability, functionality, and safety of buildings.

- Q: Can steel pipes be used for pharmaceutical manufacturing plants?

- Yes, steel pipes can be used for pharmaceutical manufacturing plants. Steel pipes are commonly used in pharmaceutical manufacturing plants for various purposes such as conveying fluids, gases, and chemicals within the facility. They are preferred due to their durability, strength, and resistance to corrosion, making them suitable for maintaining the integrity and purity of pharmaceutical products. Additionally, steel pipes can be easily cleaned and sterilized, meeting the stringent hygiene and safety requirements of pharmaceutical manufacturing.

- Q: How are steel pipes used in fire protection systems?

- Steel pipes are an integral part of fire protection systems, primarily used for the distribution of water or other fire suppressants in buildings. These pipes are known for their strength, durability, and resistance to high temperatures, making them ideal for withstanding the intense conditions of a fire. In fire protection systems, steel pipes are commonly used to create a network of pipes that deliver water to sprinkler heads or fire hydrants throughout a building. This network ensures that water is readily available to suppress or extinguish a fire in case of an emergency. One of the key advantages of steel pipes in fire protection systems is their ability to withstand the high pressure and flow rates required for effective fire suppression. Steel pipes can handle the forceful water flow needed to quickly and efficiently distribute water to the affected areas, helping to control and extinguish the fire as soon as possible. Additionally, steel pipes are resistant to corrosion, which is essential for maintaining the integrity of the fire protection system over time. Corrosion can weaken pipes, leading to leaks or even complete failure, which can be catastrophic in a fire situation. Steel pipes, however, have a longer lifespan and require less maintenance compared to other pipe materials, ensuring the system remains reliable and functional for years to come. Furthermore, steel pipes are often used in fire protection systems due to their fire resistance properties. Steel is inherently fire-resistant, meaning it can withstand high temperatures without deforming or losing its structural integrity. This is crucial in fire protection systems as it allows the pipes to remain intact and continue delivering water even in the midst of a fire, ensuring the safety of occupants and minimizing damage to the building. In summary, steel pipes play a vital role in fire protection systems by ensuring a reliable and efficient distribution of water or fire suppressants. Their strength, durability, resistance to high temperatures, and corrosion resistance make them an ideal choice for effectively combating fires and safeguarding lives and property.

- Q: Are steel pipes suitable for HVAC systems?

- Indeed, steel pipes prove to be a suitable option for HVAC systems. HVAC applications widely favor steel pipes due to their numerous advantages. Initially, their robustness and durability enable them to endure the high pressure and temperature requirements commonly associated with HVAC systems. Furthermore, steel pipes exhibit exceptional resistance to corrosion, rendering them suitable for both indoor and outdoor installations. Moreover, their extended lifespan significantly reduces the need for frequent replacements or repairs. Additionally, the availability of steel pipes in various sizes and thicknesses facilitates effortless customization and installation. Lastly, steel pipes offer a cost-effective solution for HVAC systems compared to alternative materials, making them a financially efficient choice. In conclusion, steel pipes emerge as a reliable and appropriate selection for HVAC systems due to their strength, durability, corrosion resistance, availability, and cost-effectiveness.

- Q: Can steel pipes withstand high temperatures?

- Yes, steel pipes can withstand high temperatures. Steel is a strong and durable material that has high heat resistance. It can retain its strength and structural integrity even when exposed to extreme heat, making it suitable for various high-temperature applications such as industrial furnaces, power plants, and steam pipelines.

- Q: How are steel pipes repaired in case of damage or leaks?

- Steel pipes can be repaired in case of damage or leaks through various methods. One common approach is to use a process called welding. Welding involves melting a filler material together with the damaged or leaking area of the pipe, creating a strong bond that seals the leak. This method is effective for small to moderate-sized leaks and is widely used in industries such as oil and gas, plumbing, and construction. Another method is to use mechanical couplings. These couplings are designed to join two sections of pipe together, providing a tight and secure connection. They can be used to repair damaged or leaking sections of a steel pipe by cutting out the damaged area and replacing it with a new section, which is then connected using the mechanical coupling. This method is particularly useful for larger leaks or damaged sections that cannot be repaired through welding. In some cases, a temporary fix may be applied using pipe clamps or epoxy compounds. Pipe clamps are used to tightly seal the damaged area, preventing further leakage. Epoxy compounds, on the other hand, are applied directly to the damaged or leaking area, creating a seal that temporarily stops the leak until a more permanent repair can be made. It is important to note that the method of repair will depend on the severity and location of the damage or leak, as well as the specific requirements of the application. In some instances, it may be necessary to replace the entire section of the steel pipe if the damage is extensive or if multiple leaks are present. Consulting with a professional or a specialized pipe repair service is recommended to determine the most appropriate repair method for a specific situation.

- Q: How are steel pipes tested for pressure and leakage?

- Steel pipes are tested for pressure and leakage using a variety of methods to ensure their safety and reliability. One common method is hydrostatic testing, where the pipe is filled with water and subjected to a specific pressure for a specified duration. This test helps identify any weaknesses or leaks in the pipe by observing if there is any pressure drop or visible water leakage. The pressure is carefully measured and monitored during the test, and if the pipe successfully withstands the required pressure without any signs of leakage, it is considered to have passed the test. In addition to hydrostatic testing, other non-destructive testing methods may also be employed. These methods include ultrasonic testing, which uses high-frequency sound waves to detect any flaws or defects in the pipe material, and magnetic particle testing, which involves applying a magnetic field to the pipe and inspecting it for any magnetic particles that may indicate cracks or imperfections. Moreover, visual inspection is an essential step in testing steel pipes for pressure and leakage. Trained inspectors examine the exterior and interior surfaces of the pipe to check for any visible signs of damage, such as corrosion, cracks, or faulty welds. This visual inspection helps to identify potential weak points that could lead to leaks or failures under pressure. Overall, a combination of hydrostatic testing, non-destructive testing methods, and visual inspection is used to comprehensively evaluate steel pipes for pressure and leakage. These rigorous testing procedures ensure that the pipes meet the required standards and are safe for their intended applications.

- Q: How are steel pipes used in the construction of tunnels?

- Steel pipes are commonly used in the construction of tunnels for various purposes, such as drainage systems, ventilation, and providing structural support. They are used to create efficient and durable drainage systems to manage water flow and prevent flooding in tunnels. Steel pipes are also used for ventilation systems, allowing fresh air to circulate and remove pollutants. Additionally, they can be employed to provide structural support, reinforcing the tunnel walls and ensuring stability and safety.

- Q: Can steel pipes be used for conveying hydraulic fluids?

- Yes, steel pipes can be used for conveying hydraulic fluids. Steel pipes are commonly used in hydraulic systems due to their high strength, durability, and resistance to high-pressure environments. They can effectively transport hydraulic fluids without leakage or significant loss in pressure.

- Q: Can steel pipes be used for oil refineries?

- Yes, steel pipes are commonly used in oil refineries due to their high strength, durability, and resistance to corrosion, making them suitable for transporting various petroleum products and chemicals within the refinery infrastructure.

Send your message to us

Seamless Steel Pipe ASTM A106, ASTM A53, ISO3183-2-1996 GB3087 China Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords