Sealing Machine Automatic Carton with China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

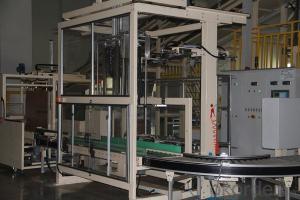

Sealing Machine Automatic Carton with China

Product Details

Basic Info.

Model NO.:SKY-FX15

Automatic Grade:Automatic

Applicable Industry:Food, Commodity, Machinery & Hardware, Medical, Alcohol and Tobacco, Textiles, Gift, Handicraft, Toy, Apparel

Application:Cleaning, Detergent, Cosmetics, Fruit Drinks, Milk, Skin Care Products, Pure Water, Yogurt, Alcoholic Beverages, Hair Care Products, Oil, Carbonated Drinks

Driven Type:Electric

Packaging Type:Cartons

Packaging Material:Paper

Export Markets:Global

Additional Info.

Trademark:Sky Machine

Packing:Wooden Case

Standard:CE

Origin:Zhangjiagang City, Jiangsu Province, China

HS Code:8422309090

Production Capacity:100sets/Year

Product Description

Automatic Carton Sealing Machine

1, Model: SKY-FX15

2, Capacity: 8-15ctn/min

Machine Features:

Automatic Carton Sealing Machine Adopt international advanced finishing equipment, processing, selection of international brands accessories.

Dominant colors this tape sealing machine is white, according to customer requirements, configuration suitable for machine production lines corresponding color;

Lightweight, pulleys complement, displacement very flexible, more convenient installation and commissioning.

According carton size, manually adjusting the width and height, simple, fast and convenient;

This adhesive tape sealing machine for packing the product lighter carton sealing, sealing effect of formation, norms, and beautiful;

Sealing tape that is affixed, rapid, easy to adjust, can be a complete upper and lower sealing action.

Paper sealing machine has been widely used in food, pharmaceutical, beverages, tobacco, chemical, automotive, cable, electronics in China and abroad.

Technical parameter:

| Model | SKY-FX15 |

| Power | 220V 50/60HZ 0.24KW |

| Suitable carton size | L150-CO*W150-500MM*H120-500MM |

| Capacity | 8-15ctn/min |

| Adhesive tape width | 48MM/60MM/72MM |

| Weight | 150KG |

| Machine size | L1020*W850*H1350MM(without conveyor) |

- Q: Where is secondhand corrugated paper packaging machinery available?

- And in the packaging materials, carton packaging accounted for a large part of the weight.Therefore, the carton factory is still very optimistic about the prospects.Business is best to have their own, if not, it is like playing a battle without vigor.But if you have better personal skills, you can also sell it to someone else's factory.After all, it is impossible to have friends and relatives need cartons, no "relationship" can be bigger and stronger.

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Buddy, you go to Taobao to buy a few hundred vacuum packaging machine, the 3 days is no problem, I suggest you go to buy a good brand, this thing hundreds of, garbage is easy to bad, shelf life 3 days, basically no problem

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packing machine? Should the packing of the tableware be contracted? Tak Cheung packing machinery, automatic heat shrinkable tableware packing machine can be considered

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- (1) urea formaldehyde moulding powder;The resin powder of urea formaldehyde resin, commonly known as electric jade powder, is produced by wet process, such as tree ester, curing agent, filler, colorant, lubricant, stabilizer, plasticizer and so on1 Components(1) resin used for urea formaldehyde resin molding powder by condensation reaction degree is relatively shallow, the resin with low viscosity, easy dipping filler, and can ensure the long production cycle and drying after proper fluidity, condensate in the industrial use of urea and formaldehyde at low temperature (a mixture of dimethylol urea, urea and formaldehyde) are usually used. The ratio of 1:1.5 (molar ratio), the PH=8 (and temperature) 30 - 35 of all dissolved, adding urea oxalate was 0.3% - 0.33% and 0.88% - 0.54% of the oxalic acid, then the occurrence of exothermic reaction, temperature rise, temperature in 55 - 60 degrees, and strictly control the PH=5.5 - 6.5, 60 - 75min by urea formaldehyde resin is required. Because the condensation degree is low, in fact just over addition reaction, condensation reaction is mainly in the curing process.(2) the curing agent used in curing agent and pressing powder requires latent, usually oxalic acid, phthalic acid, two formic acid, benzoic acid, chloroacetic acid, etc.(3) packing material is the most commonly used pulp, followed by wood powder or inorganic fillers (glass fiber, asbestos, mica etc.). The pulp is wood as raw material, with sodium bisulfite, non soluble cellulose impurities to the wood, and then byThat is the pure cellulose bleaching. The amount of filler material for the total amount of 25%-32%, the amount is too small, the pressure of plastic powder fluidity big, product strength is low; on the contrary, the amount of excessive pressure, plastic powder fluidity decreases, the product surface is not smooth, water

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: Energy saving reform of packaging machine

- First, the working principle of food packaging machinePillow type automatic packaging machine of the present domestic leading and most mature and reliable design and production technology, the essence of a collection of many years of experience in the field of packaging machinery, the packing machine can be used in a variety of composite packaging film coil on the packaging of bulk food, very suitable for the majority of users need to Chinese. 1) the electrical parts of the automatic packing machine are usually made up of the following parts:

Send your message to us

Sealing Machine Automatic Carton with China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords