High Quality Carton palletizing machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Carton palletizing machine made in China

Description of High Quality Carton palletizing machine made in China

Robotic palletizers are suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to box and palletize, canned, boxed, bottled, and other shapes of finished products. The structure is very simple, easy to maintain and repair; the main components of fewer parts, fewer parts, so the maintenance costs are very low; robot hand palletizing machine can be set in a narrow space, you can effectively use; all control can be operated on the control cabinet screen , the operation is very simple. Can work all day, equipped with robots can replace the workload of many workers.

Main Features of High Quality Carton palletizing machine made in China

1. The robot has powerful computing functions and high-precision operations, enabling rapid packing, palletizing and demolition work.

2. In the production line, the robot pallets for packing, palletizing, and demolition work can be flexibly laid out. It is ideal for palletizing at the end of the production line to palletize two or more lines at the same time.

3. The servo motors, programmable controllers, and frequency conversion speed controllers use top quality products to ensure the reliability and long life of the system hardware.

4. High-quality hardware is combined with specialized control software designed by experts to achieve a highly automated system. Perfect safety interlock mechanism can provide protection for equipment and operators.

5. Our superior technology, stable and reliable products and perfect services improve the level of factory automation.

Specifications of High Quality Carton palletizing machine made in China

| Assignment style | Horizontal gripper type |

| Productivity | 45 boxes/minute |

| Processing products | Boxes, containers, cans, etc. |

| Product conveyor belt height | 850mm |

| Tray conveyor height | 650mm |

| Tray size | 140MMH(approx) |

| Stacking method | According to user requirements |

| Pallet stacker | 15 trays as a benchmark |

| Power supply | 11Kw |

| Equipment weight | 5500kg |

| Equipment size | L8400 mm x W4700mm x H3700mm |

Applications of High Quality Carton palletizing machine made in China

Robotic palletizers are suitable for chemical, beverage, food, beer, plastics, air conditioning and other manufacturing companies to box and palletize, canned, boxed, bottled, and other shapes of finished products.

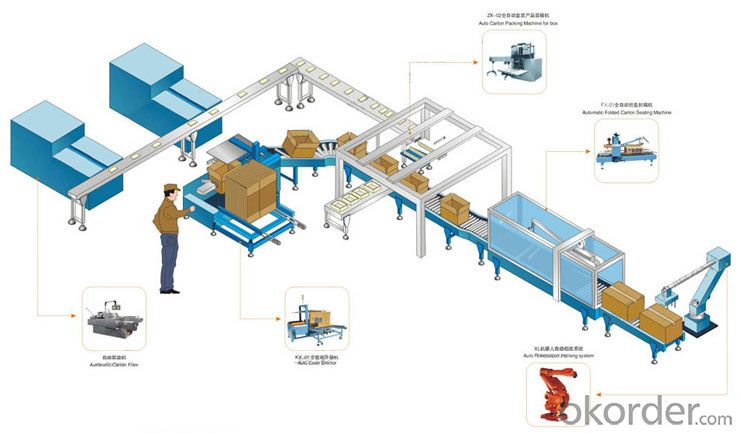

Robotic palletizers can be integrated in any production line to provide intelligent, robotized, and networked production sites, palletizing logistics for a wide variety of jobs in the beer, beverage and food industries. They are widely used in cartons, pharmaceuticals, chemicals, and beverages. , food, beer, plastics, air conditioners, plastic boxes, bottles, bags, drums, film bags and filling products. Supporting three-in-one filling lines, etc., for all types of bottles and bags for palletizing. The automatic operation of the palletizing machine is divided into steps such as automatic feeding, transfer, sorting, stacking, shifting, stacking, feeding, down stacking, and exporting.

Images of High Quality Carton palletizing machine made in China

FAQ

Q1. Does your machine fit for different volumes?

A: Yes, one machine can fill different volumes, which is based on your product information.

Q2. Can your machine reach different production?

A: Yeah, we can make machines with different of filling nozzles, and the nozzle numbers based on your production. You can adjust different filling speed within the range.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- . This is the importance of after-sales service. Qingdao Xun packaging machine models, can meet the needs of all levels.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- (1) calculate the average of two samples;(2) the variance of two samples was calculated;(3) which packaging machine is more stable in packing quality?(1) according to the average, the number divided by the sum of each group;

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: What is the working principle of the pillow packing machine?

- The sealing form - bag two sealing, a middle sealing surface,

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard specifies the terms and definitions, models, types and basic parameters, technical requirements, test methods, inspection rules and signs, packaging, transportation and storage requirements of the three-dimensional packaging machine for transparent film.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

High Quality Carton palletizing machine made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords