SAE1018 Steel Wire Carbon Rod 5.5mm Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

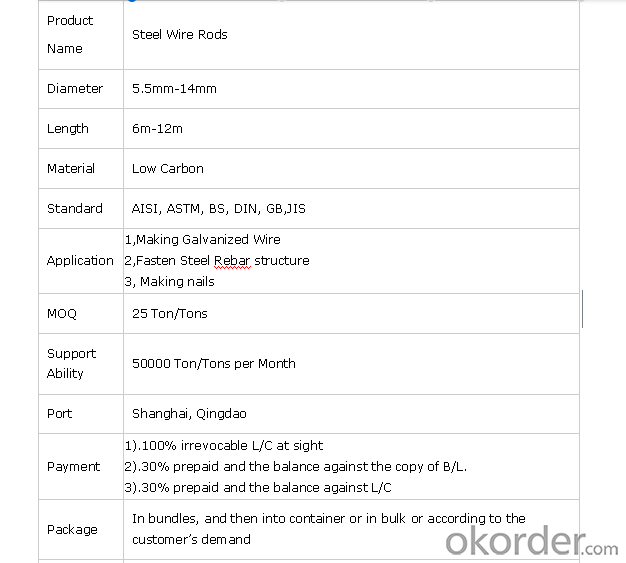

Specification

SAE1018 Steel Wire Carbon Rod 5.5mm Construction

Product Information:

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: What are the factors that affect the corrosion resistance of special steel?

- The factors that affect the corrosion resistance of special steel include the composition and content of alloying elements, surface finish and treatment, environmental conditions such as temperature, humidity, and exposure to chemicals, as well as the presence of protective coatings or inhibitors. Additionally, the manufacturing process and heat treatment can also influence the corrosion resistance of special steel.

- Q: How is special steel heat treated?

- Special steel is heat treated using a combination of heating and cooling processes to improve its strength, hardness, and other desired properties. This typically involves heating the steel to a specific temperature, known as the austenitizing temperature, followed by rapid cooling, known as quenching, to transform the steel's microstructure. This is then followed by tempering, where the steel is reheated to a lower temperature to relieve internal stresses and further enhance its mechanical properties. The specific heat treatment process and parameters vary depending on the type of special steel and the desired final properties.

- Q: Can special steel be used for making surgical instruments?

- Yes, special steel can be used for making surgical instruments. Special steel, such as stainless steel or high-carbon steel, is preferred for surgical instruments due to its excellent corrosion resistance, durability, and ability to be sterilized. These properties make it suitable for maintaining the hygiene and performance required in surgical settings.

- Q: How does special steel perform in erosion applications?

- Special steel performs exceptionally well in erosion applications due to its high resistance to wear and corrosion. Its unique composition and enhanced durability make it an ideal choice for environments where erosion is a common concern. Special steel's ability to withstand abrasive forces and maintain its structural integrity over time ensures long-lasting performance and minimizes the need for frequent replacements or repairs.

- Q: How does special steel contribute to the corrosion resistance of products?

- Special steel contributes to the corrosion resistance of products by incorporating specific alloying elements that enhance its ability to withstand the effects of corrosion. These alloying elements, such as chromium and nickel, form a protective layer on the surface of the steel, known as a passive film. This passive film acts as a barrier, preventing oxygen and moisture from reaching the underlying metal, thus reducing the likelihood of corrosion. The high levels of chromium in special steel, for example, enable the formation of a dense and stable chromium oxide layer on the surface. This layer acts as a physical barrier, preventing the diffusion of corrosive agents and inhibiting the formation of rust. Additionally, the presence of nickel in the alloy further enhances the corrosion resistance of the steel by promoting the formation of a more uniform and adherent passive film. Moreover, special steel can be specially treated or processed to enhance its corrosion resistance. Techniques such as heat treatment and surface coating can modify the structure and composition of the steel, promoting the formation of more stable passive films and reducing the susceptibility to corrosion. These treatments also help to improve the mechanical properties of the steel, making it more durable and resistant to external factors that may lead to corrosion. In summary, the use of special steel in various products contributes to their corrosion resistance by incorporating alloying elements and employing specific treatments that promote the formation of protective passive films. This, in turn, prolongs the lifespan of the products and ensures their performance and integrity, even in harsh and corrosive environments.

- Q: What are the requirements for special steel used in food processing equipment?

- The requirements for special steel used in food processing equipment include high corrosion resistance to prevent contamination, excellent hygiene and cleanability properties, high strength and durability to withstand heavy usage, and compliance with food safety regulations and standards.

- Q: What are the different methods for improving the toughness of special steel?

- There are several methods for improving the toughness of special steel. One method is through heat treatment, which involves processes such as quenching and tempering to enhance the steel's microstructure and increase its toughness. Another method is alloying, where specific elements are added to the steel composition to improve its toughness properties. Additionally, techniques like grain refinement and controlled rolling can also be employed to enhance the toughness of special steel.

- Q: How is special steel stored and transported?

- Special steel is stored and transported with utmost care to ensure its quality and integrity are maintained. Firstly, during storage, special steel is kept in a controlled environment with appropriate temperature and humidity levels to prevent any corrosion or damage. It is often stored in covered warehouses or storage facilities specifically designed for steel, offering protection from environmental factors such as rain, snow, and sunlight. When it comes to transportation, special steel is transported using various methods depending on the quantity and distance. For short distances, smaller quantities can be transported by trucks equipped with flatbeds or enclosed trailers. These trucks are designed to securely hold and protect the steel during transit, preventing any shifting or damage. However, for longer distances or larger quantities, special steel is often transported via rail or sea. Rail transportation ensures a smooth and stable journey, reducing the risk of damage due to vibrations or sudden movements. Steel is loaded onto specially designed railcars that provide secure storage and protection during transit. Sea transportation involves loading the steel onto shipping containers or directly onto specialized vessels. Containers are sealed and secured to prevent any movement or damage during the journey. Specialized vessels, such as roll-on/roll-off ships or heavy-lift vessels, are used for transporting oversized or extremely heavy steel components. In all cases, special steel is carefully packaged and secured using appropriate materials, such as wooden crates, steel strapping, or plastic wrapping, to prevent any scratches or dents. Additionally, the transportation process is closely monitored, and any necessary precautions are taken to ensure the steel arrives at its destination in optimal condition. Overall, the storage and transportation of special steel require meticulous planning, proper handling, and the use of specialized equipment to safeguard its quality and protect it from any potential damage or degradation.

- Q: What are the different defense grades of special steel?

- The different defense grades of special steel typically include grades such as AR200, AR400, AR500, and AR600, which are commonly used for protective armor and structural applications. These grades have varying levels of hardness, strength, and resistance to abrasion, making them suitable for different levels of defense against impacts, wear, and penetration.

- Q: How does special steel perform in corrosion fatigue conditions?

- Special steel is known for its exceptional performance in corrosion fatigue conditions. Corrosion fatigue refers to the combined effect of corrosion and cyclic loading, which can significantly degrade the mechanical properties of materials over time. However, special steel is specifically designed and alloyed to resist corrosion and maintain its structural integrity under these challenging conditions. The high corrosion resistance of special steel is achieved through the addition of alloying elements such as chromium, nickel, and molybdenum. These elements form a protective oxide layer on the surface of the steel, which acts as a barrier against corrosive agents. This oxide layer effectively prevents the penetration of moisture, oxygen, and other corrosive substances, reducing the likelihood of corrosion initiation and propagation. Furthermore, special steel exhibits excellent fatigue strength, allowing it to withstand cyclic loading without premature failure. Its unique microstructure, which is usually martensitic or austenitic, provides superior mechanical properties and resistance to fatigue crack initiation and propagation. This ensures that the material can endure repeated loading cycles without compromising its structural integrity. In addition to its corrosion resistance and fatigue strength, special steel also possesses good ductility and toughness. These properties are crucial in corrosion fatigue conditions as they enable the material to absorb and redistribute stress effectively, preventing localized stress concentrations that can lead to crack formation and propagation. Overall, special steel's exceptional performance in corrosion fatigue conditions can be attributed to its high corrosion resistance, fatigue strength, ductility, and toughness. These properties make it an ideal choice for applications where materials are subjected to cyclic loading and corrosive environments, such as offshore structures, marine equipment, and oil and gas pipelines.

Send your message to us

SAE1018 Steel Wire Carbon Rod 5.5mm Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords