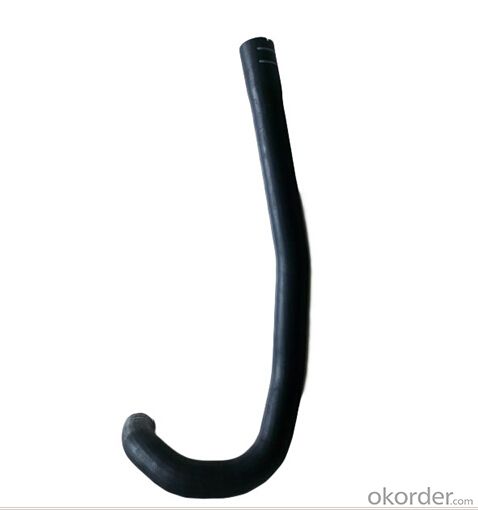

Rubber Fuel Hose High Pressure 90 Degree OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details

Material: 100% pure silicone rubber+high quality polyester

Application: turbo boost/racing/tuning/intercooler/turbo/air intake/wastegate/cooling system

Thickness:4mm-6mm

Ply:3-5

Length:50mm-2000mm

ID:3mm-150mm

Color: red, blue, black, pink, purple, yellow, green, orange, white, transparent and other colors

Working Pressure: 1.2 Mpa

Bursting Pressure: 03~0.9 Mpa

Operating Temperature: -20℃ to ~ + 260 ℃

Quality Quarantee: 5 years

Packaging & Delivery

Packaging Detail: | fuel line hoses packing(5/16 inch) 80000m/container size:long 591 cm,wide5850px,high5950px. G.W:13TON |

Delivery Detail: | 15 Days |

Product Description

Construction:

Tube:Rubber with high performance on oil resistance

Reinforcement: High tensile braid of fibers

Cover: Synthetic rubber with excellent aging resistance and weather ability. Smooth surface, concave-convex surface and cloth covered

Temparature Range:-40°C~+110°C

Specification:

NO | I.D | Refer to O.D | Working pressure | Burst pressure | approximate Weight | |||||

(inch) | (mm) | (inch) | (mm) | MPa | Psi | MPa | Psi | kg/m | lbs/ft | |

1 | 1/8 | 3.2±0.2 | 0.35 | 9±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.078 | 0.12 |

2 | 5/32 | 4±0.2 | 0.4 | 10±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.092 | 0.14 |

3 | 3/16 | 4.8±0.2 | 0.43 | 11±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.108 | 0.16 |

4 | 1/4 | 6.3±0.3 | 0.5 | 12.7±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.134 | 0.2 |

5 | 5/16 | 8.0±0.3 | 0.56 | 14±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.147 | 0.22 |

6 | 3/8 | 9.5±0.3 | 0.63 | 16±0.4 | 2.06 | 300 | 8.27 | 1200 | 0.182 | 0.27 |

7 | 15/32 | 12±0.3 | 0.75 | 19±0.5 | 2.06 | 300 | 8.27 | 1200 | 0.238 | 0.35 |

8 | 1/2 | 12.7±0.4 | 0.78 | 20±0.5 | 2.06 | 300 | 8.27 | 1200 | 0.262 | 0.39 |

9 | 5/8 | 16±0.4 | 0.94 | 24±0.5 | 1.03 | 150 | 4.12 | 600 | 0.351 | 0.52 |

10 | 3/4 | 19±0.4 | 1.13 | 28.8±0.5 | 1.03 | 150 | 4.12 | 600 | 0.515 | 0.77 |

11 | 1 | 25.4±0.5 | 1.38 | 35±0.6 | 1.03 | 150 | 4.12 | 600 | 0.637 | 0.95 |

Our Services

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What is the function of the rubber pipe joint and the installation pipe?

- The action of the rubber pipe joint on the installation of pipes:1. Small size, light weight, good elasticity, easy installation and maintenance.2. After installation, the transverse, axial and angular displacement of the pipe vibration can be absorbed. The pipe is not concentric and the flange is not parallel.3 、 after installation, it can reduce the noise caused by vibration of pipes, pumps and so on, and has strong vibration absorption ability.

- Q: What are the production processes and characteristics of high pressure rubber hose?

- According to the knitting process, the high-pressure hose is divided into high-pressure steel wire braided hose and high-pressure steel wire winding hose.

- Q: What is the method of making large diameter rubber joint?

- Rubber joint also known as shock absorber, shock absorber throat, the main function is to shock absorption, noise reduction, protection of the pipeline, compensation pipeline expansion, cold caused by displacement.Its structure: both ends are two carbon steel flanges, the middle is rubber shock absorption part.

- Q: Latex tube, rubber tube, silicone tube, which three of the best tightness?

- Rubber tightest is butyl rubber, rubber pipe products in general, with no fiber layer, expanding 300-500% is no problem, you can put it into the glass tube, depends on the strength of the glass tube and technique.

- Q: Natural gas can be connected to a gas cooker. Can rubber tube be used?

- Yes, rubber hoses are required for selection of rubber hoses.

- Q: The basic buret is a rubber tube is inlaid with a glass bead to replace glass piston. Why this burets cannot be used to install Potassium Permanganate solution?

- Are made of glass, acid burette glass piston burette, no piston, just at the tip of a rubber tube, rubber tube with glass beads, glass or the lower beak. Why not the same because of acid burette, glass and alkali reaction, generate silicate, sticky, if it is very easy to use acid burette, the hole is blocked, damaged burets.

- Q: Is flexible rubber joint and telescopic device a kind of thing?

- The main features of metal pipe telescopic device are telescopic, large compensation and high temperatureUnder great pressure.And flexible rubber joint is a product!

- Q: Why should liquefied petroleum gas use strong rubber hose and liner?

- Commonly called liquefied petroleum gasMain ingredients: ethylene, ethane, propane, propylene, butane, butene, etc. (oil resistance will accelerate swelling and aging).Appearance and properties: colorless gas or yellow brown oily liquid, has a special odor.In order to remind people of the leakage of liquefied petroleum gas in a timely manner, the processing plant often mixes a small amount of foul odor mercaptan or thioether compounds into liquefied petroleum gas, which is the source of special odor.These gases on the rubber has a certain corrosion, swelling (not resistant to oil will speed up swelling), aging effect, liquefied petroleum, so choose rubber seal to consider oil resistance, corrosion resistance, swelling!

- Q: Hydraulic hose joint configuration

- Well control hose connector: composed of a core rod and sheathed and connected with the sleeve is characterized in that the outer surface of the core rod and the sleeve on the surface along the circumferential direction of the corresponding is provided with at least 1 slots with each other and clasp. The utility model has the advantages of high temperature resistance, high pressure and resistance to pull out of the rubber tube, and is especially suitable for the connection hose of the oil well drilling control device.

- Q: Three yuan ethylene propylene rubber tube covered with nylon PA66, what glue can not afford the layer?

- Because the nylon 66 excellent heat resistance, chemical resistance, strength and convenient processing, so it has been widely used in the automotive industry, currently has almost all parts for automobile, such as engine parts, electrical parts and body parts.

Send your message to us

Rubber Fuel Hose High Pressure 90 Degree OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords