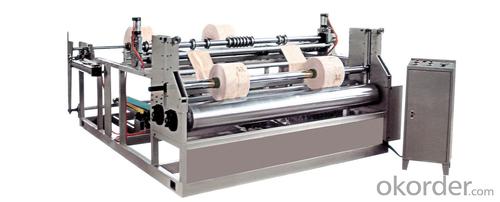

Roll to Roll Paper Slitting Rewinding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roll to Roll Paper Slitting Rewinding Machine Function

1. Double blades (upper blades and down blades) slitting. Cutting edges are more smooth and neat.

2. Adopt shaftless material loading device which can bear 2000kgs weight.

3. Pneumatic loading and unloading system; material paper roll loading and finished rolls unloading to be automatically.

Roll to Roll Paper Slitting Rewinding Machine Technical Parameters

Technical Parameter | Control System | ||

Material Paper | 40-600gsm | Main Motor | 15kw Wannan |

Unwind Width | 600-1600mm | Inverter | 18.5KW Delta (Taiwan) |

Unwind Diameter | 1200mm (standard) | Lifting Motor | 1.1kw*2 pcs Wannan |

Rewind Diamter | 1200mm (standard) | Clamping Motor | 1.5kw *2 pcs Wannan |

Minimum Slitting Width | 35mm | Execute Components | CHNT |

Working Speed | 0-250 meters/min | Signal Components | Hugong |

Speed regulation | By Inverter | Pneumatic Components | Jingwei |

Material Loading Device | Shaftless Device | Electric Components | CHNT |

Loading Type | Automatically by Pneumatic (hydraulic can be customized) | Bearing | Haerbin |

Rewinding Type | Air Inflation Shaft | Configuration | |

Unloading Type | Automatically by Pneumatic | Material Paper Fixing Cone | 2 Pieces (76mm ID) |

Power Supply | 380V/3Phase/50Hz (can be customized) | Lifting Air Cylinder | 2 Pieces |

Discharging Air Cylinder | 2 Pieces | ||

Size | Material Shafts Braking Device | 2 Sets | |

Mainframe (two parts) | 3000*1700*1100mm (Unwinding side) | ||

Blades | 20 Sets (standard) | ||

3300*1200*1200mm (Rewinding side) | Operating Box | 1 Set | |

Curved Roll | Have | ||

Weight | 3200kgs | Meter Counter | Optional |

Enclosed Spare Parts | Automatic Correcting Unit | Optional | |

Useful Tool | 1 Set | ||

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: What are the main plastic forming processes?

- 3. cold pressing molding. Cold pressing molding is also called cold pressing sintering molding. The difference between the cold press molding and the ordinary compression molding is that the material is pressurized and molded at room temperature. The mold after release can be heated or cured by chemical action. This method is used in the forming of polytetrafluoroethylene and some high temperature resistant plastics (such as polyimide, etc.). The general process is three steps of billet sintering cooling.4. transfer molding. Transfer molding is a molding process for thermosetting plastics. When molding, the mold is heated and softened in the heating chamber and then pressed into the mold cavity where it has been heated. According to the different types of transfer molding equipment form: trap type; the tank; the piston.The requirement of plastic molding for transfer molding is that the plastic should have a greater fluidity before reaching the curing temperature, and the curing rate must be faster at the curing temperature. Phenol, melamine, formaldehyde and epoxy resins can meet this requirement.Transfer molding has the following advantages: less waste edge products, can reduce the processing quantity; second molding with fine or brittle insert and perforation of the products, and can keep the insert and the hole position is correct; the product performance is uniform, accurate size, high quality; the mould wear small. The disadvantage is that the manufacturing cost is high compression mold die; the plastic loss; the fiber reinforced plastics for fiber orientation and anisotropy; and around the insert around the plastic, sometimes due to melting is not strong and make the products according to the strength reduction.

- Q: A & B two sets of packaging machines, at the same time packaging quality of 500 kilograms of goods

- 10 bags were randomly extracted from each of them, and the actual quality was measured as follows: (unit G)A: 501500503506504506, 500498497495B: 503504502498499501, 505497502499

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: What does the mechanical equipment include?

- Hydraulic lifting track machineHydraulic tamping machine, rail sawing machine, rail machine

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

Send your message to us

Roll to Roll Paper Slitting Rewinding Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords