Ringlock Easy Assembly Top Quality Metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

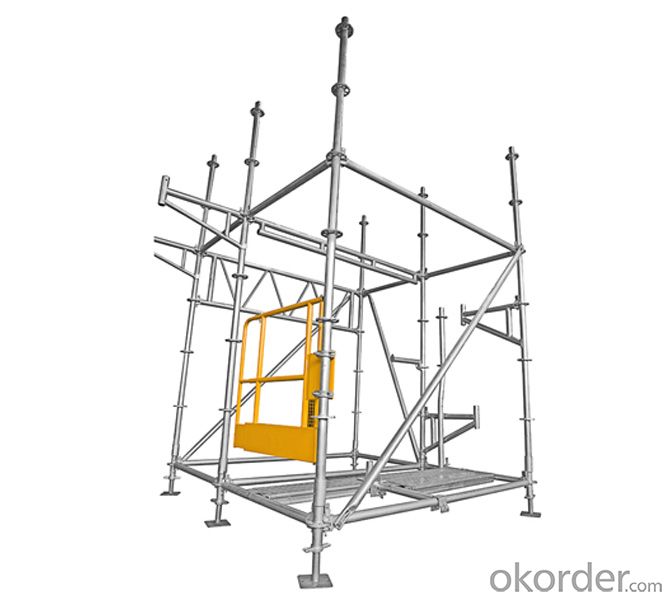

Ringlock Scaffolding

Ringlock is a modular scaffold system which can provide major savings in labor costs while meeting the demands for safety, ease of handling and reductions in maintenance.

Ringlock scaffold has the following features:

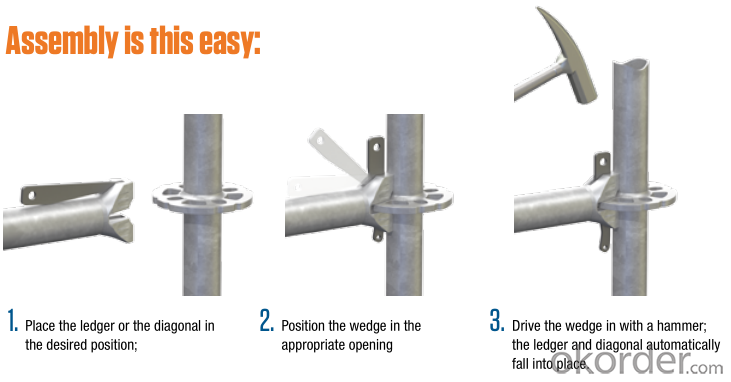

1.Quick erection: Ringlock scaffold are all pre-measured and just a hammer is required when erection.

2.Safety: The reliable wedge connections prevent ledgers and diagonal braces from any kind of loosening, The rigid, right fit of all connections with concentric derivation of loads guarantees safety even at great heights.

Main Features of the Ringlock Scaffolding

Place of Origin | Beijing, China (Mainland) |

Product Name: | Ringlock Scaffolding |

Custom Code | 7308400000 |

Color | Silver, golden |

Surface treatment | Painted,Hot-Dip,Galvanized,Electro Galvanized, Powder Coating |

Material | Q235,Q345.etc |

Package | Customized Package |

Payment Terms | T/T,L/C |

Delivery Detail | 15-25 Days |

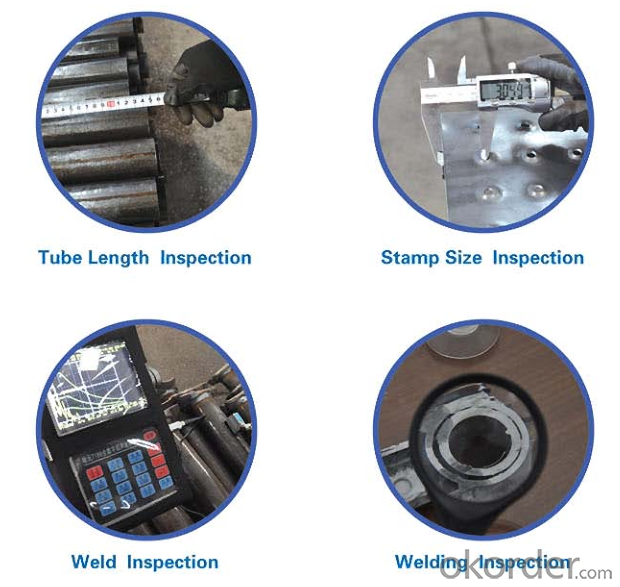

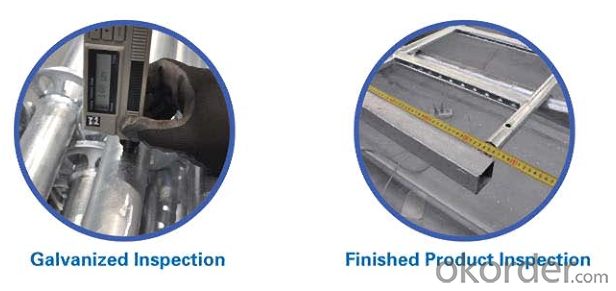

Quality Control | IS09001 Certification, Quality Test |

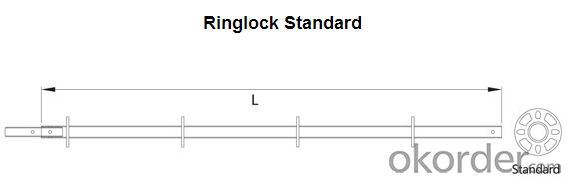

Standard | 48.3*3.25*4000mm |

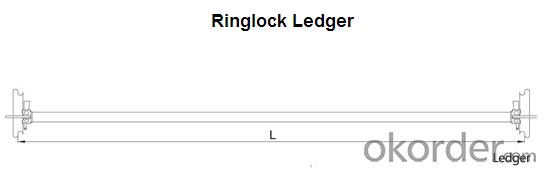

Ledger | 48.3*3.25*3072mm |

Ledger End | 1.2kg |

Advantages

1)To be erected easily and quickly

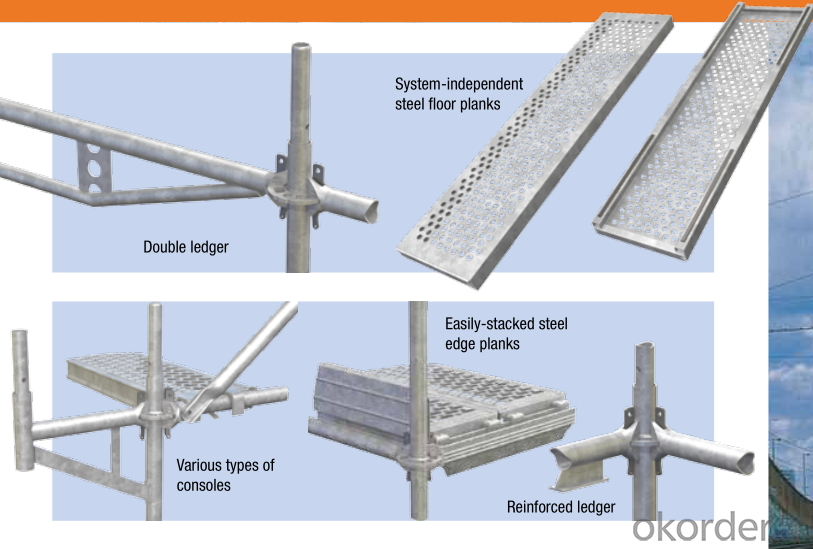

2)Installed to different angels with rosettes of

two different hole being positioned there

3)Ringlock scaffolding provides complete flexibility to lock in any angel.

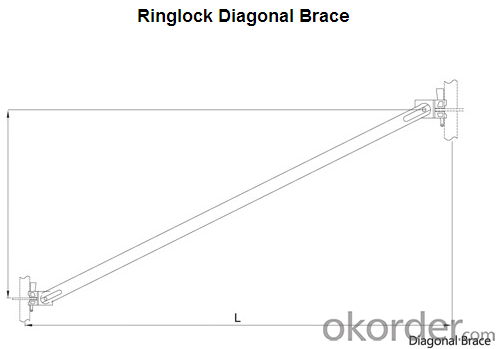

4)Diagonal braces are to be tailored in

accordance with the lengths of vertical and horizontal tubes

Specification of Ringlock Scaffolding

The Standards(Verticals) | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

3000 | 3/3.25 | 48 | HDG/Painted | |

2500 | 3/3.25 | 48 | HDG/Painted | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1500 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

500 | 3/3.25 | 48 | HDG/Painted | |

The Ledgers(Horizontals) | ||||

Effective Length(mm) | Tube Thickness(mm) | Tube Diameter | Surface Treatment | |

2000 | 3/3.25 | 48 | HDG/Painted | |

1770 | 3/3.25 | 48 | HDG/Painted | |

1000 | 3/3.25 | 48 | HDG/Painted | |

The Diagonal Brace | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

2411 | 3 | 48 | HDG/Painted | |

2244 | 3 | 48 | HDG/Painted | |

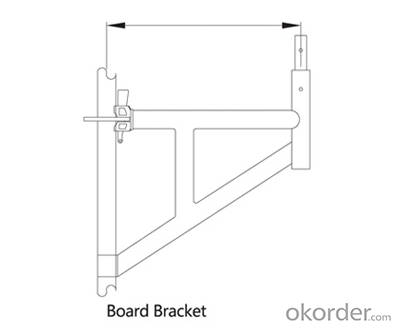

The bracket | ||||

Length(mm) | Tube Thickness(mm) | Tube Diameter(mm) | Surface Treatment | |

730 | 3 | 48 | HDG/Painted | |

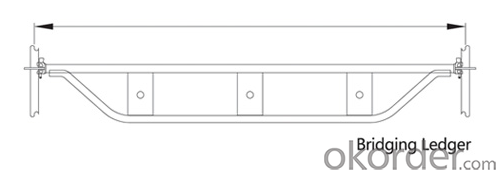

Plank | ||||

Effective Length(mm) | Width(mm) | Height(mm) | Surface Treatme | |

2050 | 480 | 45 | HDG | |

1820 | 480 | 45 | HDG | |

3000 | 240 | 45 | HDG | |

2000 | 240 | 45 | HDG | |

1000 | 240 | 45 | HDG | |

Hollow Head Jack And Jack Base | ||||

Length(mm) | Tube Diameter(mm) | Size of Plate(mm) | Surface Treatment | |

600 | 38 | 150*120*50*4 | HDG | |

600 | 38 | 150*150*4 | HDG | |

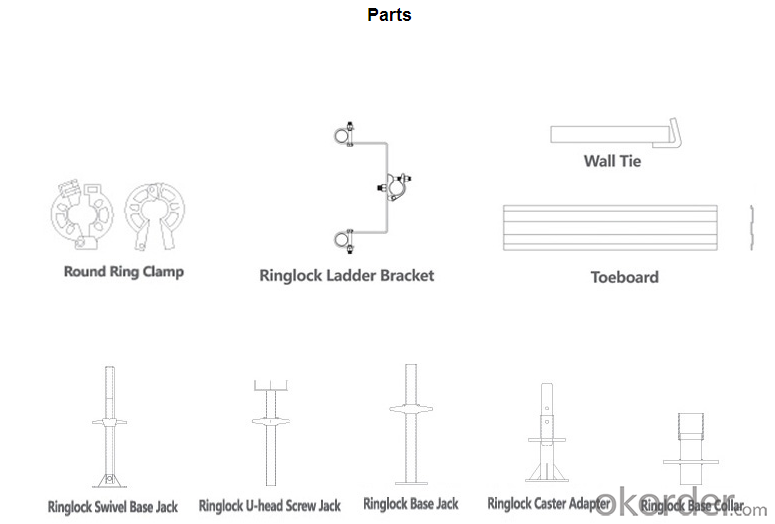

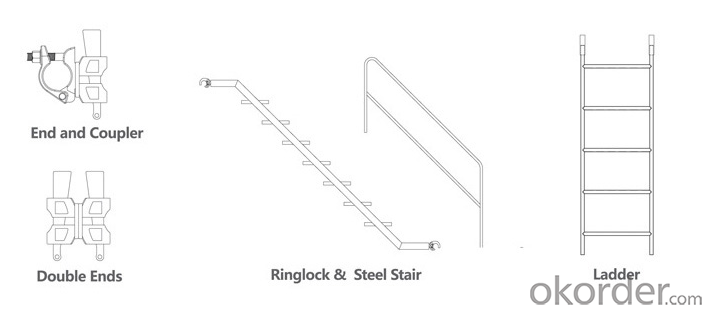

Accessories

Packing

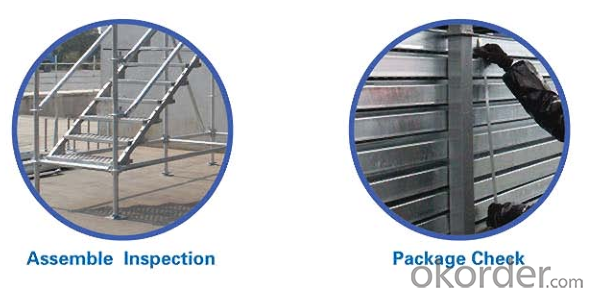

Inspection

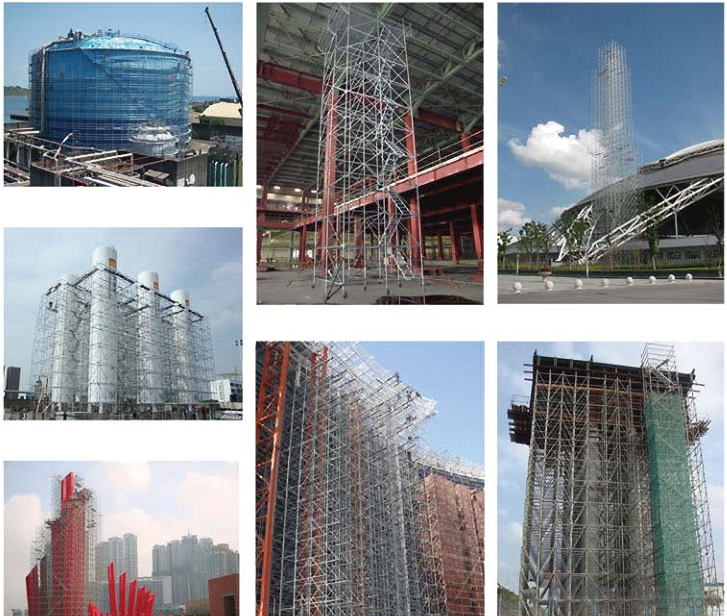

Project

More Photos

- Q: for how long must hester prynne stand on the scaffold ? The Scarlet letter a?

- I don't know, but you know who does probably know? Nathaniel Hawthorne. Why don't you read that book he wrote, the scarlett letter. The answers probably in there.

- Q: Specification for bowl scaffold support top rod length of not more than 30cm, which is the standard which page specific ah, too lazy to check out, who knows?

- Specification for bowl scaffold support rod top length of not more than 30cm

- Q: left end. What is the Tension in EACH wire??can anyone help

- And you asked this physics question in the math section of answers because? Let Tl and Tr be the tensions in the left and right wires. We are told the weight of the box is W and that the scaffold is weightless.

- Q: how much does a scaffolding business earn a year?

- Given the collapsing housing and construction sectors of the economy, it's highly likely that few if any scaffolding companies are making so much as pennies these days.

- Q: Hey guys, so I got my scaffolding (ear) done yesterday. My piercer told me NOT to clean it, and that the best thing for a cartilage piercing is to quot;leave it bequot; I trust this advice, but I wanted to ask your opinion or methods that worked for you :) Thanks lt;3

- nonono, industrials or notorious for infections. if you don't clean it, imagine how much bacteria is going to be near it since all the folds of the ear and the oils or your hair. I clean my industrial at least twice daily, and I have yet to get an infection though. What I do is Sea Salt Soaks in the morning and night. I put a little emu oil to advoid hypertrophic scarring. and I have kept my hair up every day since getting it pierced to make sure my hair doesn't irritate it while its still in its early healing phase.

- Q: How come wwe doesn't have any barb wire rope or scaffold match?

- Because they're on basic cable? Seriously, barbwire matches are extremely violent and not worth the risk, and Scaffold matches are all payoff and no good build. I've only seen two watchable scaffolding matches in my life. One was between the Free Birds and the Road Warriors, the other was Rhino and AJ in TNA. A good, entertaining scaffolding match is hard to pull off, and not worth the risk of injury. I guess the correct answer is Vince McMahon cares about money, and to injure a major draw in such a stupid, boring, one-spot-wonder like a Scaffold Match is just bad business. As for barbwire rope matches, they limit what you can do in the ring, you'd be surprised how claustraphobic it can be for a wrestler who can't leave the ring, go up top, or hit the ropes, not to mention the major risk. I mean, have you seen what happened to Sabu during the Funker/Douglas/Sabu match back in ECW? One of the sickest scars ever.

- Q: On my blackberry so bare with me, I got my scaffold pierced on monday, everything fine, monday night I saw a lil blood clot scab thing...being an idiot I picked it, since then its non stop bled on and off, its now wednesday and its bleeding heavily, I don't know what to do, it soaks up pads of tissue in minuets.Anyone have any suggestions? Thankyou x

- Did you try peroxide? Put some on a cotton ball and clean around the piercing. If this does not go away within two days and the bleeding persists your body may be rejecting the metal from your skin. This will cause the peircing to eventually migrate out. Go back to the piercer and see what they say.

- Q: I got mine done about 10 weeks ago, with the two rings either side of the ear to give it healing space, then about 2 weeks ago, got the bar put through it... but I still can't sleep/lie on it comfortably. How long after getting the piercing, roughly, have people been able to sleep on their without it hurting?

- It takes 6-12 months for a cartilage piercing to heal when done properly with a needle and double that time if a gun was used. I don#x27;t know why they pierced you with rings (should never be used in a scaffold#x2F;industrial piercing) and especially why they changed it to a bar so soon. You should have been pierced with a bar to begin with because changing the jewelry like that causes irritation and prolongs healing time. I think you need to find a different piercer.

- Q: I have to write an essay on the use of the scaffold in the novel. The first use is in the beginning when Hester is standing on it for public punishment. The third time is at the end, when Dimmesdale pleads for forgiveness and then dies. I am confused on the second time it is used. Any ideas?

- The second time is like the turning point of the novel i believe. I think it was acceptance and purging. Don't they feel better after that? Its the same principle when Dimmesdale goes through the forest and comes out feeling better. Its the beginning of them purging for their sins. I think that the second time could be labeled as confession, actually Because they all meet up and its discovered that Dimmesdale is an adulterer as well. So go with that, confession and purging, haha I read it last year; we totally did an essay on it too. (and i totally aced it! whattt) haha Hope this helps!

- Q: how much compensation can i get for falling of scaffolding and breaking my arm?

- Clumsiness? Zero.

Send your message to us

Ringlock Easy Assembly Top Quality Metal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords