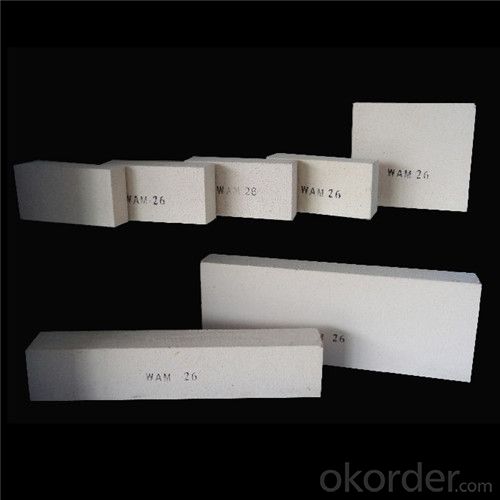

High Alumina Brick for Blast Furnace and Ball Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Refractory High Alumina Brick for Blast Furnace Ball Mill

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | Uncertain | Al2O3 Content (%): | ≥60% | MgO Content (%): | Uncertain |

| CaO Content (%): | Uncertain | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | Uncertain |

| SiC Content (%): | Uncertain | Model Number: | LNHAB14001 | Brand Name: | |

| Apparent porosity,%: | 18-22% | Cold Crushing strength Mpa: | 45-80Mpa | Fe2O3 %: | ≤2.0% |

| Sample Request: | Free | Advantage 1: | The most competitive price | Advantage 2: | Abundant Experience |

| Advantage 3: | Different Moulds. Save mould fees for you | Advantage 4: | Large stocks. Guarantee prompt delivery | Advantage 5: | Professional Packing |

| Advantage 6: | Lower ferric Oxide,porosity,density,higher CCS and exact tolerance |

Packaging & Delivery

| Packaging Details: | Packed on wooden pallets with water-proof cover, and tightened with plastic/steel bandages |

| Delivery Detail: | In 20 days after prepay |

Specifications

Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

5.ISO certificate

Description:

High alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. The main mineral components are corundum and mullite phases. It features excellent high temperature mechanics and chemical corrosion resistance.

Features

1.Resisting high temperature

2.Great bulk density

3.Low iron content

4.Good eroding resistance

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Specifications:

Ordinary High alumina brick

Item | HA60 | HA70 | HA75 | HA80 |

AL2O3(%) | ≥60 | ≥70 | ≥75 | ≥75-80 |

SIO2(%) | 32 | 22 | 20 | ≥18 |

Fe2O3(%) | ≤1.8 | ≤1.8 | ≤1.8 | ≤1.8 |

Refractoriness °C | 1790 | >1800 | >1825 | ≥1850 |

Bulk density,g/cm3 | 2.4 | 2.45-2.5 | 2.5 | 2.55-2.6 |

Softening temperature under load | ≥1470 | ≥1520 | ≥1530 | ≥1550 |

Apparent porosity,% | 22 | <21 | <21 | <20 |

Cold Crushing strength Mpa | ≥45 | ≥50 | ≥54 | ≥60 |

Phosphate bonded high alumina bricks

Item | L75 | L77 | L85 |

AL2O3 % | ≥75 | ≥77 | ≥80-85 |

Fe2O3 % | ≤3.0 | ≤3.0 | ≤1.8 |

Ca0 % | ≤0.6 | ≤0.6 | ≤0.6 |

Refractoriness °C | ≥1800 | ≥1800 | ≥1850 |

Bulk density g/cm3 | ≥2.65 | ≥2.70 | ≥2.80 |

Cold crushing strength MPa | ≥60 | ≥64 | ≥110 |

Refractoriness under load 0.2MPa °C | ≥1350 | ≥1300 | ≥1350 |

Application | Used for high temperature parts lining of cement rotary kiln | Used for Badly worn parts of cement rotary kiln | |

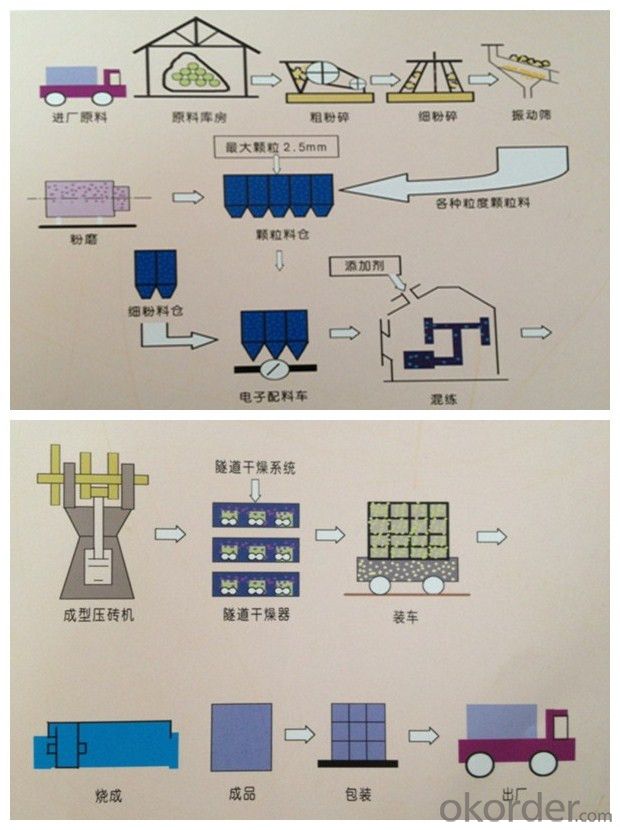

Process flowdiagram:

After the contract is signed, the relevant responsible person tracked production progress, product quality and product packing aperiodically. During the term of contract sent on time with quantity and quality guaranteed.

FAQ

1.Are you a manufacturer or trader?

Factory + trade (mainly factories, at the same time, we operates other related products)

2.Can we visit your factory?

Sure,welcome at any time,seeing is believing

3.What's the MOQ of trial order ?

No limit,We can offer the best suggestions and solutions according to your condition.

4.Which payment terms are you accept?

T/T,LC,Western Union,moneygram,Paypal are available for us.

5.After an order is placed, when to deliver?

15-25days

6.Is your company accept customization?

We have own factory and excellent technical team, and we accept OEM service.

7.How about your company's certification?

SGS,ISO9001 and Test Report,also we could apply other necessary certification.

8.How to solve the quality problems?

If the products are not conform to customer samples or have quality problems, our company will be responsible to make compensation for it.

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: What are the high aluminum bricks made of?

- We specialize in the production of various LeiBao refractory refractory material, such as corundum, zirconia products, alumina hollow ball products, mullite products and so on.

- Q: Application characteristics of high alumina brick

- Slag resistance. Due to the high alumina brick products in the three oxidation of two aluminum is neutral and high content, so this material products for acid-base slag corrosion resistance.

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.The water absorption rate of the first grade high alumina bauxite clinker should be less than 5%, and the water absorption rate of two grade high alumina material should be less than 7%. Fine grinding of soft clay and bauxite clinker with less than 4% water content. Mixed fine milling ingredients with this, can reduce the porosity of bricks.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: How to distinguish the good or bad of the high aluminum brick?

- The general high alumina bricks used in the steel, steelmaking, hot blast furnace, electric furnace, blast furnace, reverberatory furnace, rotary kiln lining of industrial furnace in China, mainly composed of a bauxite; sillimanite minerals (including kyanite, andalusite, sillimanite etc.); synthetic material, such as alumina synthesis of mullite, corundum, etc.. High aluminum brick has good quality, high refractoriness, long life and other characteristics, is the main use of refractory brick kiln products, commonly used units can not distinguish the quality and grade of high aluminum brick right in the procurement time, caused by the high prices to buy low grade products, thereby reducing the furnace life therefore, Zhengzhou's Sindh yuan refractory material factory in here is simple to introduce how to identify the quality when purchasing brick high alumina brick.Color: in the purchase of high alumina brick, first of all to see the color, high quality aluminum brick surface smooth, yellow color white, four sides smooth, no broken angle, no cracksWeight: the weight of a block of bricks to be called, according to the standard weight level, high aluminum brick weight of 4.5 kg. Two grade high alumina brick weighs 4.2 kg, three high aluminum brick weighs 3.9 kg, the same level, the same parameters can reach this standard can be regarded as high-quality high aluminum bricks, the opposite is not up to the weight that the quality is good, if there is a crack, four angle uneven, off angle phenomenon, then substandard products, some of the above points to help to the purchaser

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- The expansion of high alumina brick is not only related to temperature, but also related to its material composition. The refractory temperature of high alumina brick is above 1770 centigrade. The temperature of 800 DEG C has little influence on the expansion of high alumina brick.

- Q: What kind of material is the general metal case?

- Ordinary computer chassis and the material itself does not produce high-energy radiation, only in the space environment of the computer is the external defense requirements, and in the space structure, the use of lead as protective materials, unbearable weight.

- Q: The difference between clay bricks and clay bricks

- According to the hole rate: solid brick (no hole or hole rate less than 25% bricks), porous brick (hole rate is equal to or greater than 25%), the size of the hole is small and the number of bricks, usually used in load-bearing parts, higher strength level. Hollow brick (hole rate equal to or greater than 40%, large pore size and small amount of brick, commonly used in non load parts, low strength grade).Solid bricks and porous bricks are mostly used for load-bearing structural walls. Hollow bricks are mostly used in non load bearing structures.

Send your message to us

High Alumina Brick for Blast Furnace and Ball Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches