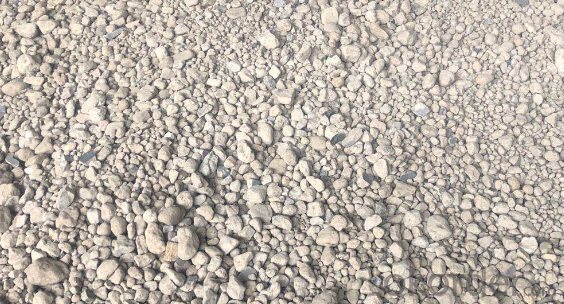

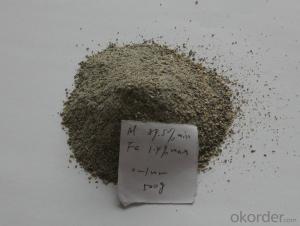

REFRACTORY GRADE CALCINED BAUXITE WITH COMPETITIVE PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Shanxi, China

· Shape: Block or grain size or powder

· Material: Alumina

· SiO2 Content (%): 4%-24%

· Al2O3 Content (%):70%-90%

· MgO Content (%):+CaO 0.8%MAX

· CaO Content (%):+MgO 0.8%MAX

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: Calcined bauxite

· Color: Gray or Cyan

· Size:50MESH/100MESH/200MESH/325MESH/0-1MM/1-3MM/3-5MM/0-40MM

· BULK DENSITY:2.6-3.3G/CM3

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q: Can someone professionally introduce the classifications of refractories?

- It can be divided into two categories of ordinary and special refractory. Ordinary refractories can be devided into acidic, neutral and alkalinee refractories according to chemical properties. Special refractory can be devided into high temperature oxide, refractory compounds and high-temperature composite materials according to the compositions. Furthermore, it canbe devided into ordinary refractory products (1580 ~ 1770 ℃), advanced refractory products (1770 ~ 2000 ℃) and super refractory products (above 2000 ℃) according to the strength of refractoriness. It can be divided into bulks (standard brick, special-shaped brick, etc.), special shape (crucible, sagger, pipe, etc.), fibrous (aluminum silicate, zirconia and boron carbide, etc.) and Indefinite shape (refractory clay, castableand ramming mass, etc.) according to the shapes of products. According to the sintering process, it can be divided into sintered products, cast products, melting jetting products.

- Q: How much is refractory spraying coatings?

- This depends on whether you use the thin coatin or thick coating. Then it depends whether you use an aqueous coating or oily one. Usually thick aqueous coating is 2-3 dollars per kilogram. While the thin is six or seven dollars per kilogram. The oily coating is more than ten dollars. The prices obtained from the Internet is for reference only.

- Q: What is the strength of high strength refractory material?

- With the help of high temperature and load, refractory material deforma to a certain degree of temperature from the beginning of deformation (load softening point), known as high temperature structural strength or high load softening temperature. It is a the ability to resist deformation ih high temperature and load at the same time. The nature of the high temperature is very improtant for selection of a furnace building materials under the effect of high temperature and force.

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- I am engaged in construction. Refractory material does not necessarily belong to construction industry. Fire resistance is only a part of material?performance. Indeed, there are many places requiring refractory accorded with fire resistant level.

- Q: What is the difference between wear-resistant material and refractory material?

- There must be difference. The requirements of refractory material are that it can be called refractory material when temperatures it can withstand are over 1570 ℃. Refractory material must have high strength. The specific value of refractory material is not clear.

- Q: For refractory knowledge. What is the ratio of clay ramming?mass?

- Soil aggregates, dispersing agent, water reducing agent, plasticizer, binding agent and powder! ~ Bone meal feed approximately 6, OK

- Q: who knows the requirements of refractory for forge furnace?

- Requirements are as follows: 1, it should have enough refractoriness and softening point under a fixed load. Because under the effect of electric arc, inner surface temperature in different parts of furnace lining can reach 1500 ~ 1800 ℃. 2, it should have strong slag resistance. Because slag and smoke at high temperature penetrate through furnace lining to its internal lining, causing the melting of refractory, organization stratification, and even peeling?off. 3, it should have good thermal shock resistance. Because in the process of steelmaking, openning the oven door and lifting the furnace lid will make temperature of refractories in the furnace lining change rapidly, it might happen peeling?off and cracking, causing the premature failure of furnace lining. 4, it should have sufficient strength, because the furnace lining will be shocked when being loaded, vibrated when being tilted, scoured by metals,molten slag and air flow when boiling. 5, smaller thermal conductivity, lower electrical conductivity. Commonly used refractories for electric furnace include magnesia bricks, dolomite brick, high alumina refractory brick, siliceous refractory brick and magnesite ramming material,etc. owing to the different work environment of each part of the furnace,refractory used by each part is also different.

- Q: Would you like to know if there are any enterprises in Mianyang that need fire-resistant materials?

- I only know that the Stone Town Youxian district with a fire stopping collar.

- Q: What kinds of refractory materials that uses a-Al2o3 powder? What are the purpose of it?

- 04La-Al2O3 powder is a alumina powder whose raw material is industrial aluminum oxide which has been calcined at high temperature. It is a good polishes for ceramics and jade, meanwhile, it is also an important raw material for high-end refractory materials. The technical indicators parameters A1023 mark A1535 chemical composition AL2O3≥ 99.92 3%, ≥ 3.10FE203≤ 0.799 Refractory calcined alumina powder (a-Al2O3) 1.2 true density (g & # 47, by fully ground powder made of different fineness .O.10 0.07 0.04NA2O≤ 0.93a-Al2O3 (%) ≥ 95 95 primary crystallization average grain (um) 2 ~ 3 3 ~ 5 average particle size (um) 40 ~ 602.6SIO2≤ 0.1 0.15B2O3≤ - 0, glass, engineering ceramics typical use electronic ceramic insulating ceramic refractory ceramic wear 3

Send your message to us

REFRACTORY GRADE CALCINED BAUXITE WITH COMPETITIVE PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords