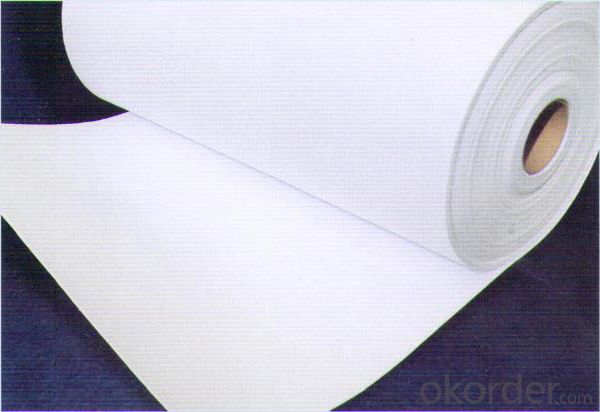

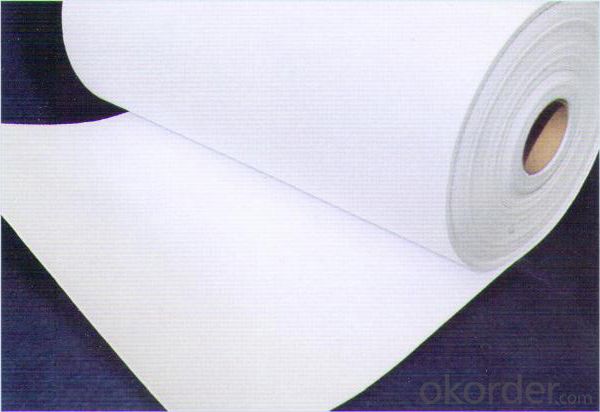

Rock Wool Refractory Ceramic Fiber Paper Fireproof Rigid Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 11111 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Company information

CNBM, China National Building Materials Group Corporation is leading in building materials and equipment industry. CNBM is also pioneer in providing reliable high quality refractories with technical expertise and logistic solution. CNBM is your one stop source of supply for wide range of refractory products. You can find out more extensive technical data and services at our website. Our aim is to develop a long term business relationship with customers or partners to achieve a competitive pricing and services. Continuous strive for product Excellency in term of material quality and customer satisfaction is our mission. We look forward to hearing your valuable enquiries or technical question in due course.

CMAX ceramic fiber blanket is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. Double-side needling provides blanket with great tensile or handing strength for easy installation. The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃,1100℃,1200℃ and 1350℃

Feature

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent(shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

Physical & Chemical Data

Description | 1000 NATI Ceramic Fiber Blanket | 1260 NATI Ceramic Fiber Blanket | 1425 NATI Ceramic Fiber Blanket | 1500 NATI Ceramic Fiber Blanket | 1600 NATI Ceramic Fiber Blanket |

Classification temperature( ℃) | 1000 | 1260 | 1425 | 1500 | 1600 |

Melting point( ℃) | 1760 | 1760 | 1800 | 1900 | 2000 |

Color | White | White | White | Green-blue | White |

Average fiber diameter (um) | 2.6 | 2.6 | 2.8 | 2.65 | 3.1 |

Fiber length (mm) | ~250 | ~250 | ~250 | ~150 | ~400 |

Density for fiber (Kg/ m3) | 2600 | 2600 | 2800 | 2650 | 3100 |

Shot content ( > 212um) (%) | 12 | 12 | 12 | ||

Thermal conductivity rate Kcal/mh℃ (W/mK) ,ASTM C201 | |||||

Average 400℃ | 0.08 | 0.08 | 0.08 | ||

Average 600℃ | 0.19 | 0.12 | 0.12 | ||

Average 800℃ | 0.19 | 0.16 | 0.16 | ||

Average 1000℃ | 0.23 | ||||

Chemical composition : | |||||

Al2O3 | 43 | 45 | 35 | 40 | 72 |

SiO2 | 55 | 52 | 46.7 | 58.1 | 28 |

ZrO2 | 15-17 | ||||

- Q: What does the rock wool board look like?

- What does the rock wool board look like?

- Q: What role does dolomite play in rock wool products?

- Rock wool is a traditional insulation material, because it is inorganic materials, insulation performance is not very good

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Burning performance: Combustion performance refers to all the physical and chemical changes that occur when the building material is burned or in case of fire. This performance is caused by the fire and flame propagation of the material surface, heat, smoke, carbonization, weight loss, and toxicity And other characteristics to measure. The burning performance of the products of rock wool products is zero.

- Q: The difference between rock wool and rock wool

- The difference between rock wool and rock wool

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Fire protection and noise reduction of the elevator shaft of the building wall, the roof of the insulation, the firewall, the fire door, the large and medium diameter pipes, the small and medium sized storage tanks, the kilns, the thermal power plants, Boilers and other equipment insulation.

- Q: Rock wool board is inorganic composite insulation material

- Rock wool composite insulation material depends on what you compound the material

Send your message to us

Rock Wool Refractory Ceramic Fiber Paper Fireproof Rigid Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 11111 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords