Rock Wool Heat Resistant Fireproof Ceramic Fiber Paper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 111111 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

China Supplier Heat Resistant Fireproof Ceramic Fiber Paper

Product Description

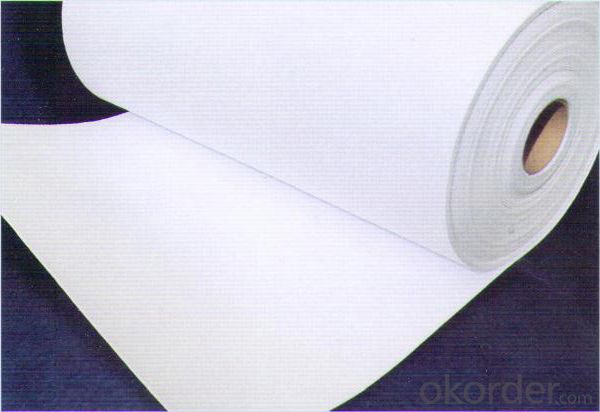

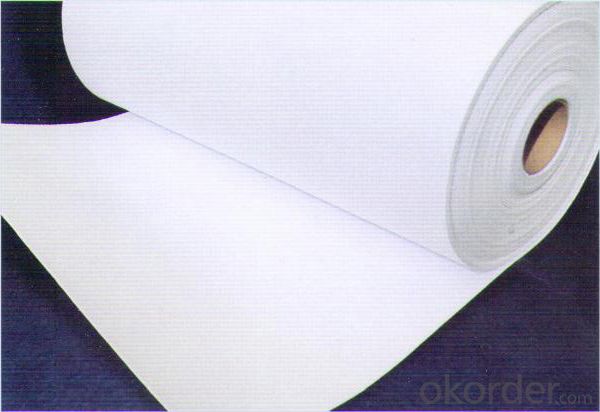

Ceramic Fiber Paper Introduction

Ceramic Fiber Paper takes ceramic fiber as main raw material, using wet paper molding process to be made, with the advantage of good resistance to high temperature, low thermal conductivity, corrosion resistance. Products are divided into: common, high pure, high aluminum, zirconium type aluminum silicate ceramic fiber, which been made well by series processing of needling, cutting and rolling.

Ceramic Fiber Paper Specification

Types | Standard | High Pure | High Aluminum | Zircon | |||

Classification Temperature | 1050 | 1260B | 1260HB | 1360 | 1430 | ||

Shrinkage on Heating (%) | 800°C×24h≤-3 | 1000°C×24h≤-3 | 1280°C×24h≤-3 | 1400°C×24h≤-3 | |||

Organic Content | ≤10 | ||||||

Thermal Conductivity by Mean Temp. (W/m.k.) (250kg/m3) | 200 | 0.055~0.065 | 0.060~0.070 | ||||

400 | 0.110~0.0120 | 0.105~0.125 | |||||

600 | 0.160~0.170 | 0.170~0.180 | |||||

Density (kg/m3) | 180~200 | ||||||

Normal Size (mm) | 60000x610/1220x1 | 30000x610/1220x2 | 20000x610/1220x3 | ||||

15000x610/1220x4 | 12000x610x1220x5 | 10000x610/1220x6 | |||||

Other size on your request | |||||||

Ceramic Fiber Paper Feature

Good handling strength

Low thermal conductivity and heat storage

Excellent thermal shock resistance

Easy machining

Low weight; Elastic; Flexible

Excellent hydrophobic property

Smooth surface and anti-tearing

Ceramic Fiber Paper Application

Insulation of high-temperature pipe and instruments

Sealing for valve and flange

Covering Material for fireproofing cable, cloth, high temperature expanding material

Insulation off fireproofing refrigeration engineering in transportation, construction,petrochemical industry, electric power industry.

Special high temperature equipment (high-temperature resistance furnace, induction furnace, Ladle lid, glass glass melting furnace, kiln car, high-temperature radiant tube, high-temperature vessel, hot-blast furnace, burner) in Metallurgy, scientific research, spaceflight and nuclear reaction industry.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- What role does dolomite play in rock wool products?

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Heat load shrinkage temperature: heat load shrinkage temperature used to characterize the rock wool board moisture and heat stability, is to wet the rock wool product samples soaked in the gradual heating of water, rock wool products at a temperature of 643 degrees will begin to shrink , So rock wool products load shrinkage temperature of 643 degrees, that is to say in the outside temperature of 643 degrees when the rock wool board will be deformed.

- Q: The difference between rock wool and rock wool

- Rock wool can also be made with glass wool aluminum silicate composite made of rock wool composite insulation pipe.

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- With low thermal conductivity, the use of high temperature, fire non-flammable, construction convenience, energy-saving effect is remarkable, there is a high cost performance. Adiabatic with rock wool, mineral wool and its products for a variety of pipe insulation and fire protection

- Q: Rock wool board is inorganic composite insulation material

- Insulation material A-level fire is organic meet the inorganic meet resolutely

Send your message to us

Rock Wool Heat Resistant Fireproof Ceramic Fiber Paper

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 111111 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords