Raw Materials for Refractory - High Content Manesia Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

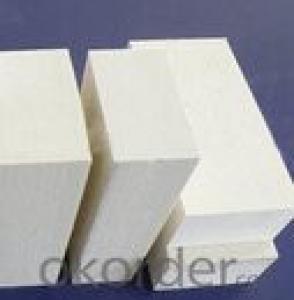

Features:

1. Low thermal conductivity, good thermal insulation performance.

2. Long service life, easy operation, could be shaped freely

3. Product specification: standard form, normal standard, shaped and special shaped bricks.

4. Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Applications:

1. Carbon bake furnaces in the aluminum industry

2. Preheat zones and cyclones of rotary cement kilns

3. Insulation for glass tanks

4. Fireplace and pizza ovens

5. Coke ovens

6. Blast furnaces

7. Reheating furnaces

8. Suspended roofs

9. Lime kilns

10. Chimney

Specifications:

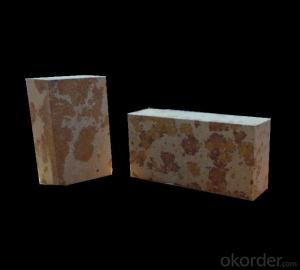

Thermal Insulation Fire Clay Brick, Firebrick Refractory For Coke Ovens, Blast Furnaces, Suspended Roof

Technical data

Item | AL-30 | AL-34 | AL-38 | AL-45 | AL-55 |

AL2O3 % (min) | 30 | 34 | 38 | 45 | 55 |

Fe2O3% (max) | 3 | 3 | 2.8 | 2.8 | 2.6 |

Refractoriness | 1670°C | 1710°C | 1750°C | 1770°C | 1770°C |

Refractoriness under load, 0.2MPa, (°C) | 1250 | 1300 | 1350 | 1450 | 1470 |

Apparent porosity (%) | 22-26 | 22-26 | 20-24 | 20-22 | 20 |

Bulk density (g/cm³) | 1.9-2.1 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.2-2.35 |

Cold crushing strength (MPa) | 20 | 25 | 30 | 35 | 40 |

Thermal expansion at 1000°C (%) | 0.8 | 0.6 | 0.6 | 0.5 | 0.4 |

Competitive Advantage:

1 Competitive Price. Make the products competitive in your market.

2 Abundant Experience. Prevent cracks and twist in bricks.

3 Different Moulds. Save mould fees for you.

4 Strict Quality Control. Meet clients’ quality requirement.

5 Large stocks. Guarantee prompt delivery.

6 Professional Packing. Avoid damage and secure the goods in transportation

FACTORY:

- Q: How to divide the fire resistant level of EVB?

- 1. The thermal insulation material of level A combustion performance: Inorganic fiber spray coating, glass wool, foam glass, foamed ceramics, rock wool, foam cement and hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3, combustion performance is level B2 insulation material: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. I hope I can help you!

- Q: How to divide fire rating of decorating materials ?

- Decorating materials shall be divided into four levels according to combustibility. Level A: noninflammability; B1: difficult-flammability; B2: combustibility; B3: inflammability.

- Q: What is the best refractory company?

- Palladium activity is very rich ah, Sina micro-blog introduced a lot of jewelry related content, style is very unique, see people could not help but want to store to buy impulse.

- Q: As for fireproofing material rock wool and glass wool, which one is better?

- First of all, glass wool and rock wool fireproof materials, rock wool and glass wool belong to Class A fireproofing rating, secondly, rock wool can endure high temperature of 800 degrees, glass wool high temperature of 450 degrees, again,unit weight of rock wool is relatively heavier and unit weight of glass wool is lighter, finally, glass wool has better waterproof performance.

- Q: whether the fire resistant level of aerated concrete building blocks can reach the grade one?

- the fire resistant level of aerated concrete building blocks can reach the grade one level. Aerated concrete strength grade shall be divided according to the concrete cubic compressive strength value. Use the symbol C and the cube compressive strength value (in N / mm2 or MPa gauge) to express. According to GB50010-2002 "concrete structure design specifications" provisions, ordinary concrete is divided into fourteen levels, namely: C15, C20, C25, C30, C35, C40, C45, C50, C55, C60, C65, C70, C75, C80 .

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- This is the use of steel tapping water procedures inside!!

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: What are the materials of class A fire resistant window?

- Environmentally friendily, non-poisoned non-peculiar smell, non-radioactive; non-combustible, fireproof, moisture-proof, corrosion-resistant; easy to operate, lightweight, high strength, themal insulation, sound insulation; able to be cut, planed, sawed and carved. It also meets GB8624 -2006A1 level non-combustible standards. Lightweight, high strength, anti-aging, corrosion resistance; meeting the GB / T20285-2006 Opium (AQ1) safety and environmentally friendly products; Foamed fire door core board specifications: 2100 × 900 × (26 ~ 65) mm; 2050 × 850 × (26-65), and many other specifications. I hope my answer can help you.

- Q: What's the A class fireproof and thermal inuslation matertial for external wall?

- It is a kind of green and environmental protection inorganic material, free of harmful substances like asbestos, benzene, formaldehyde, etc. Its fire resistance can be up to A1grade non-combustible material, which means it can endure the highest temperature of 1400 ℃. It is thermal insulating with low heat conductivity and high heat storage coefficient. It has good weather resistance, finished product stability, anti hollowing, crack resistance, wind pressure and shock resistance with the same service life as buildings of 70 years. It is water-fast and moistureproof, breathable but waterproof, and fungusproof without influence from steam. It is convenient in construction which omits many procedures of panels construction. Once the second plastering is finished, the construction is completed, which greatly shortens the construction period. It has good adhesive property with various base planes, and meanwhile its external exposed surface can choose coating, facing brick, aluminum sheet, marble, etc. It saves money. Excellent construction technology reduces the construction cost. It effectively prevents the panels from leakage at the external wall, window, eave, etc. which saves the subsequent maintenance fund. It provides timely delivery. With sufficient supplies of raw materials and convenient production, it is fast in delivery.

- Q: Pals who know something about fire resistant material please tell me how many types of refractory material there are

- Refractory materials used in special applications include high temperature oxcide, such as alumina, lanthanum oxide, beryllium oxide, calcium oxide, zirconia and other, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, mainly contain metal ceramic, high temperature inorganic coatings and fiber reinforced ceramics.

Send your message to us

Raw Materials for Refractory - High Content Manesia Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords