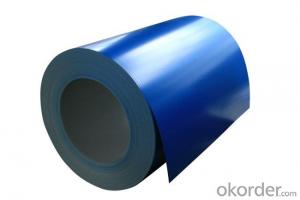

RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 28000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

Description of RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; auto parts etc.

Specifications of RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

Product | RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each color. And we could give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your can offer the better price we can provide.

2. How long can we receive the product after purchasing?

Usually within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15- 25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common coil tests performed for quality control?

- Some common coil tests performed for quality control include tension tests, bend tests, hardness tests, and dimensional checks. These tests help to ensure that the coils meet the required specifications and are of high quality.

- Q: I have a Nike SQ Sumo 21 degree and it is a steel shaft. I hit the ball very high with this club and I lose distance. I don't hit any of my other clubs high it's just this one. Is it because of the steel shaft or is it the club? Help please.

- if you are a good player they say steel shaft is better. more consistent. I prefer graphite its lighter and I can flip my wrists easier.

- Q: How are steel coils used in the manufacturing of body reinforcements?

- Steel coils are used in the manufacturing of body reinforcements by being shaped and welded to form sturdy structural components, such as pillars, beams, and frames, that provide strength and rigidity to the vehicle's body structure.

- Q: What is the maximum width of steel coils?

- The maximum width of steel coils is subject to variation, influenced by factors like steel type, manufacturing capabilities, and intended usage. Nevertheless, in most cases, steel coils tend to have a maximum width of approximately 2,200 millimeters or 86.6 inches. This width is widely employed in the steel industry for coils of standard sizes. It is worth mentioning that wider widths may be achievable through specialized steel coils or custom manufacturing methods, albeit less frequently and possibly necessitating particular equipment or processes.

- Q: I want to build an indoor riding arena, should I go for Steel ones.

- Though okorder /.. You can also have a look!!

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- There are many ways in welding stainless steel, such as coating manual welding,argon arc welding, pulsed argon arc welding, MIG, pulsed MIG, double pulsed MIG. Different welding ways own their merits and faults and adaptive working conditions. It is recommended to choose pulsed MIG, its molding very good and efficiency high, so it is mainstream application for stainless steel welding. Now many digital welding machines can supply these welding methods at the same time. And their welding effects is far better than traditional machines. Among them, FRONIUS’s TPS series and Nebula series are representitive products.

- Q: How do steel coils contribute to the agricultural sector?

- Steel coils contribute to the agricultural sector by being used in the manufacturing of agricultural machinery and equipment. These coils are used to create components such as plows, harrows, tillers, and seeders, which are essential for cultivating, planting, and harvesting crops. The durability and strength of steel coils make these agricultural machinery and equipment more robust, reliable, and efficient, thereby improving productivity and ensuring higher crop yields.

- Q: Can you suggest me names of sites which aids in construction of Pre Fabricated Steel Buildings.

- A word of caution, there are many bad steel building contractors out there. Stay with reputable brands such as Butler, Behlen, and Whirlwind. A broker such as Heritage will get you good results but I have heard horror stories about a lot of steel building brokers.

- Q: Which one would be stronger? And should damascus steel be tempered?Thank You

- Damascus steel is in history books only,no body knows its composition.THey just named a modern steel as Damascus steel

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

Send your message to us

RAL Scale Z40 Prepainted Rolled Steel Coil for Construction Roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 28000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords